High yield crystallized diabetin production process

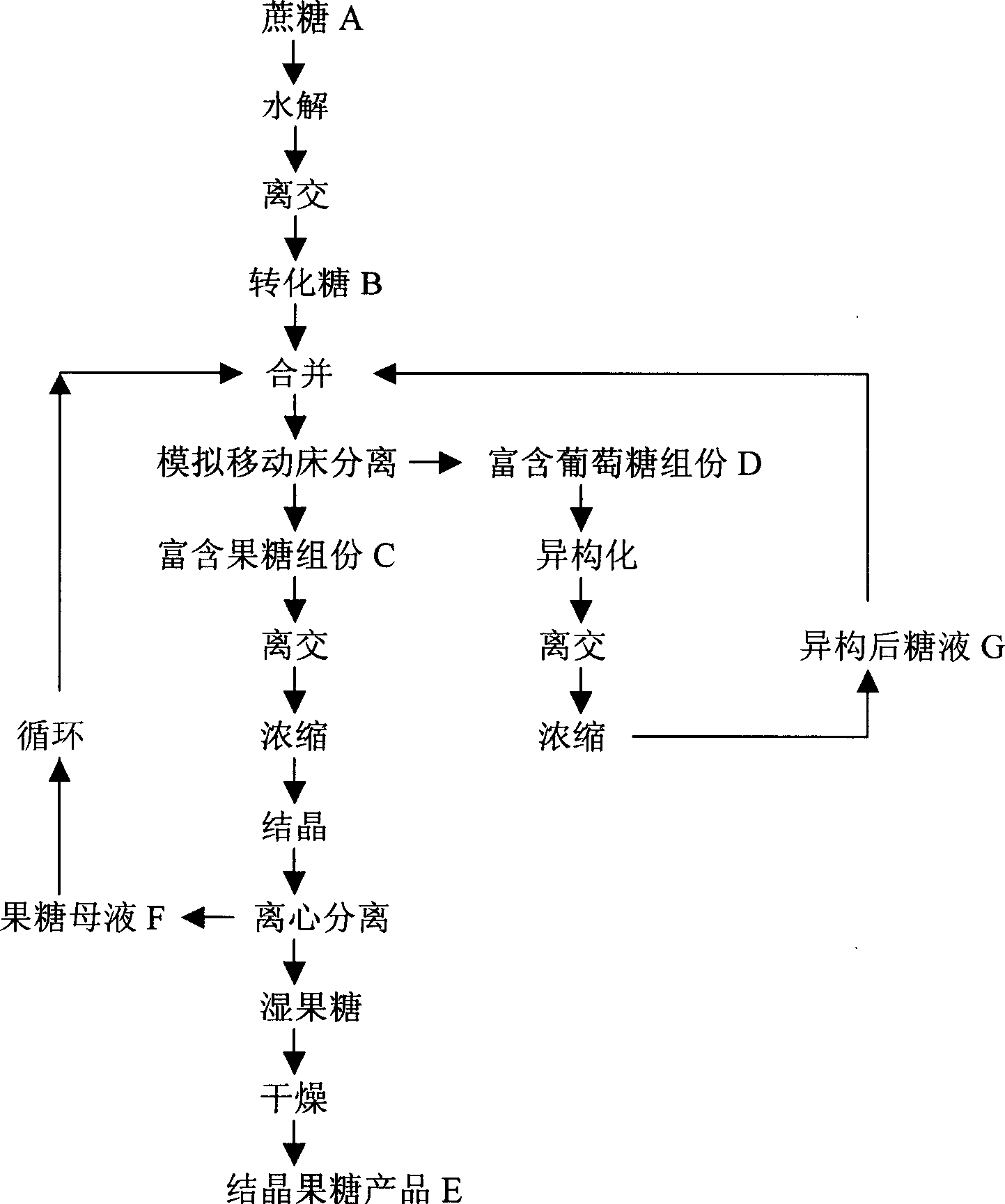

A high-yield technology for crystalline fructose, applied in the field of preparation of organic compounds, can solve problems such as the inability to realize industrialized production, the high production cost of crystalline fructose, and the inability to meet market needs in large quantities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: 1000 grams of edible white granulated sugar was dissolved in 1000 ml of deionized water to obtain a 50.14% aqueous solution of sucrose, and 50 ml of industrial hydrochloric acid was added to adjust the pH of the sugar solution to 2.18, and then the solution was heated at a temperature of 98 ° C. Stirring and reacting for 1.5 hours, then using cation and anion exchange resin columns to separate and remove impurities to obtain 1940 grams of refined invert sugar solution, the concentration of the sugar solution is 51.55%, containing 49.75% fructose, 49.82% glucose, and 0.43% other small amounts of impurities. %.

[0025] Use a simulated moving bed device to separate and treat the invert sugar solution, the feed concentration is 51.55%, and at a separation temperature of 58°C, with water as the eluent, the operations of feed, water, and discharge are continuously performed to obtain fructose-rich Component discharge and glucose-rich component discharge, the quali...

Embodiment 2

[0028] Embodiment 2: get 2138 grams (concentration is 24.32%) of the glucose-rich component obtained in example 1, contain fructose 6.2% in the dry matter, contain glucose 93.4%), add 6 grams of flake solid sodium hydroxide, The pH value of the sugar solution is adjusted to 10.60, then heated and kept at 65°C, stirred and reacted for 0.5 hours, then treated with cation and anion exchange resins, the separated sugar solution is collected, and concentrated under vacuum -0.06Mpa to a concentration of It is 41%, obtains 1260 grams of sugar liquid after isomerization, contains fructose 28.5% in its dry matter, compares with before isomerization, and fructose content rises to some extent, proves that alkali isomerization reaction is effective thus.

[0029] The purpose of Example 2 is to generate fructose from the isomerization of glucose-rich components, which is an important step in the high-yield production of crystalline fructose according to the present invention.

Embodiment 3

[0030] Embodiment 3: 235 grams (dry matter) of the fructose mother liquor obtained in Example 1 are combined with 1260 grams of the isomerized sugar solution obtained in Example 2 and 490 grams of fresh invert sugar B, and stir evenly to obtain mixed sugar Liquid 1946 grams, concentration is 51.5%, wherein fructose content is 47.76%, and glucose content is 49.50%.

[0031]Utilize the simulated moving bed device to separate and treat the obtained mixed sugar liquid, when the feed concentration is 51.5%, the separation temperature is 58°C, and water is used as the eluent, the feeding, water feeding and discharging operations are continuously carried out to obtain respectively The fructose-rich component and the glucose-rich component are 1550 grams, the concentration is 29.62%, and the fructose content is 93.73%; the glucose-rich component is 2180 grams, the concentration is 24.83%, and the fructose content is 7.1%. Contains 92.3% glucose.

[0032] 1550 grams of fructose-rich c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com