Radiation polymerization method for aqueous polyurethane-siliceous acrylic resin fabric coating

A water-based polyurethane, silicone acrylic technology, applied in textiles and papermaking, etc., can solve problems such as the research stage of fabric coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

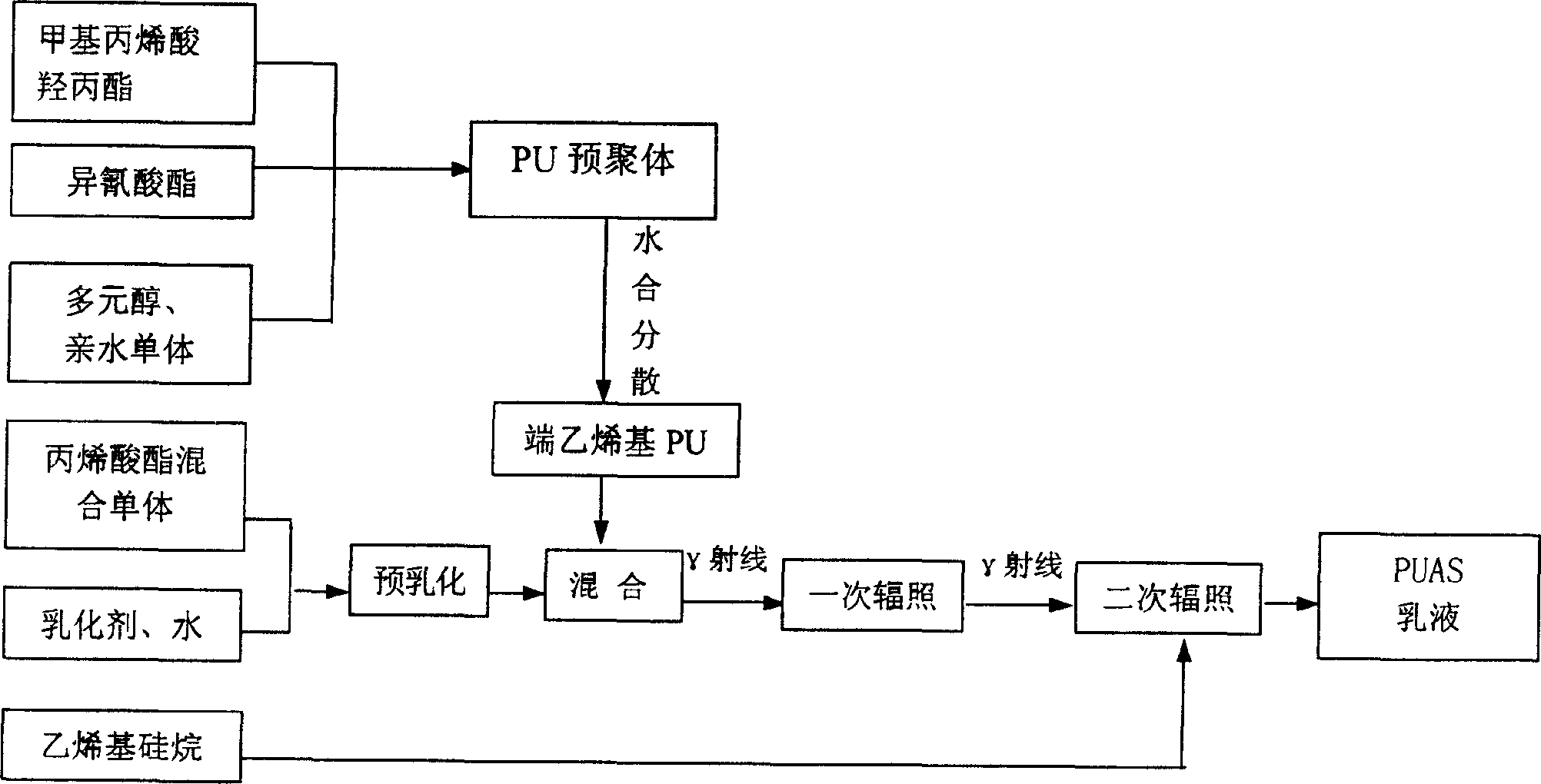

Method used

Image

Examples

Embodiment 1

[0065] The specific synthesis operation method is as follows:

[0066] 1. Preparation of vinyl terminated polyurethane emulsion

[0067] Put ethylene oxide diol polyether diol into the stainless steel reaction kettle, dehydrate in vacuum at 100-120 °C for 2 hours; then cool down to 80-90 °C, add toluene diisocyanate, and keep the reaction at 85-90 °C for 2 hours; At 70°C, the hydrophilic monomer dimethylolpropionic acid, the chain extender diethylene glycol, and β-hydroxypropyl methacrylate were added, and the reaction was incubated for 3 hours. During the reaction, acetone should be added if the viscosity is high. Cool to below 30°C, add neutralizing agent triethylamine, stir for 2-5 minutes, add water under high-speed stirring (1400 rpm-2500 rpm) to disperse into water emulsion, remove acetone in vacuum, prepare Outlet vinyl PU emulsion.

[0068] The consumption of each component in above-mentioned technological process is as follows:

[0069] Polyoxyethylene ether glyco...

Embodiment 2

[0090] The specific synthesis operation method is as follows:

[0091] 1. Preparation of vinyl terminated polyurethane emulsion

[0092] Put polyoxypropylene-ethylene oxide polyol into the stainless steel reaction kettle, dehydrate it in vacuum at 100-120°C for 2 hours; then cool down to 80-90°C, add cyclohexane diisocyanate, and keep the reaction at 85-90°C for 2 hours; cool down to 80-90°C At 70° C., add hydrophilic monomer dimethylol propionic acid, chain extender ethylene glycol, and β-hydroxyethyl methacrylate, and keep reacting for 3 hours. During the reaction, acetone should be added if the viscosity is high. Cool to below 30°C, add neutralizing agent triethylamine, stir for 2-5 minutes, add water under high-speed stirring (1400 rpm-2500 rpm) to disperse into water emulsion, remove acetone in vacuum, prepare Outlet vinyl PU emulsion.

[0093] The consumption of each component in above-mentioned technological process is as follows:

[0094] Polyoxypropylene-ethylene ...

Embodiment 3

[0108] The specific synthesis operation method is as follows:

[0109] 1. Preparation of vinyl terminated polyurethane emulsion

[0110]Put polyester polyol into the stainless steel reaction kettle, dehydrate in vacuum at 100-120 °C for 2 hours; then cool down to 80-90 °C, add 1,6-hexamethylene diisocyanate, and keep the reaction at 85-90 °C for 2 hours; At 70°C, the hydrophilic monomer dimethylolpropionic acid, the chain extender diethylene glycol, and β-hydroxyethyl methacrylate were added, and the reaction was incubated for 3 hours. During the reaction, acetone should be added if the viscosity is high. Cool to below 30°C, add neutralizing agent triethylamine, stir for 2-5 minutes, add water under high-speed stirring (1400 rpm-2500 rpm) to disperse into water emulsion, remove acetone in vacuum, prepare Outlet vinyl PU emulsion.

[0111] The consumption of each component in above-mentioned technological process is as follows:

[0112] Diethylene glycol adipate polyester p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com