Optical interconnection coupling structure based on soft photoetching

A coupling structure and soft lithography technology, which is applied in the coupling of optical waveguides and other directions, can solve the problems of the alignment tolerance accuracy falling to 0.1-0.3mm, the manufacturing process is complicated, and the mass production is difficult, so as to achieve flexible design and high coupling efficiency. , The effect of easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

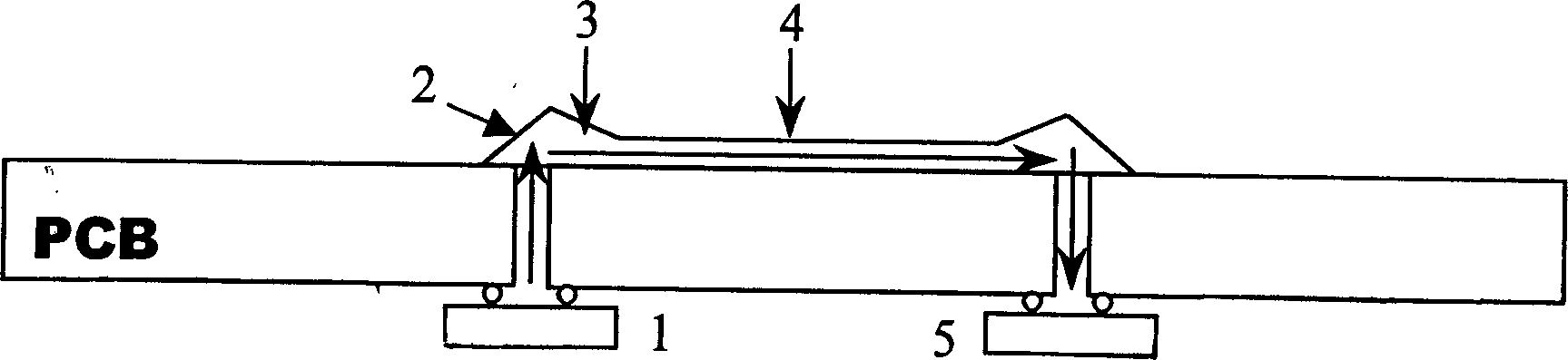

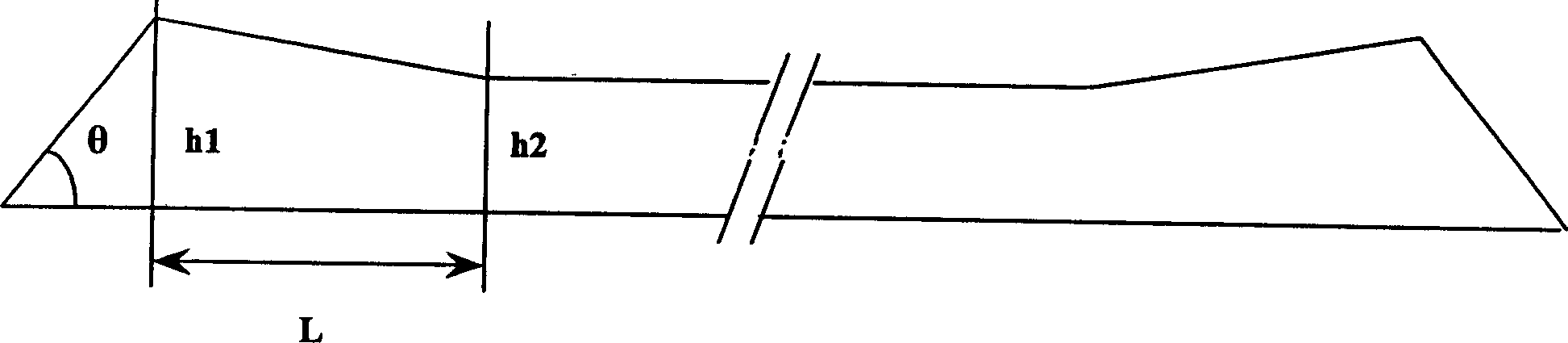

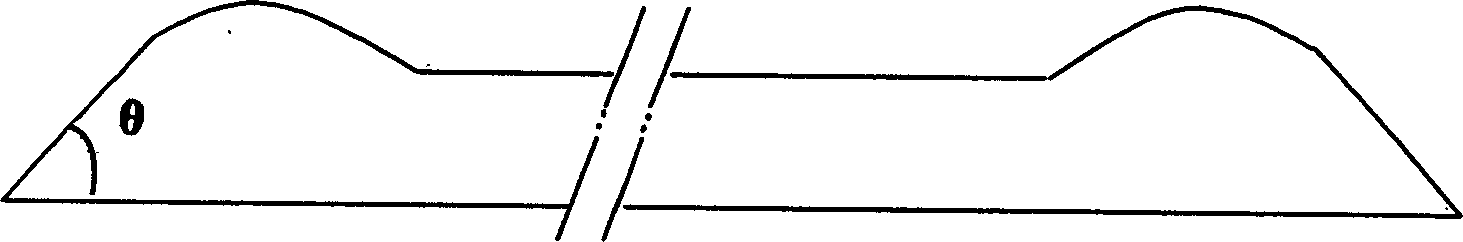

[0018] Such as figure 1 As shown, it includes a light source 1, two reflective surfaces 2, two intermediate coupling sections 3, a square wave guide 4, and an optical receiver 5. A reflecting surface 2 and an intermediate coupling section 3 are connected to one side of the square wave guide 4 in sequence, and the other intermediate coupling setting section 3 and the other reflecting surface 2 are connected to the other side of the square wave guide 4 in sequence , A symmetrically connected connector is installed on the printed circuit board. The printed circuit board has two through holes. The light source 1 and the light receiver 5 are placed on the other side of the printed circuit board. The light source 1 passes through the first through hole. Aligned to one reflective surface 2, the light receiver 5 is aligned to the other reflective surface 2 through the second through hole.

[0019] The light source 1 is a vertical cavity surface emitting laser with an operating wavelength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com