Method for preparing in-situ silver-carried natural zeolite deiodinating adsorbent

A natural zeolite and adsorbent technology, applied in chemical instruments and methods, silicate, inorganic chemistry, etc., can solve the problems of high production cost, easy crushing and pulverization, complex preparation process, etc., and achieve easy quality, low cost, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention comprises the following steps:

[0029] 1. Direct ammonium or acid exchange of raw ore:

[0030] Ammonium exchange: exchange 0.5-1.0mm raw ore zeolite with 0.5-2mol / l ammonium salt solution, the solid-to-liquid ratio is 1:10, heat to 95-100°C and reflux for 2 hours, exchange four times, wash with water, and dry.

[0031] Acid exchange: exchange 0.5-1.0mm granular raw ore zeolite with 0.5-1.0mol / l acid solution, the solid-liquid ratio is 1:10, stir at room temperature to 100°C for 2 hours, exchange 3-4 times, wash with water and dry .

[0032] 2. Silver loading

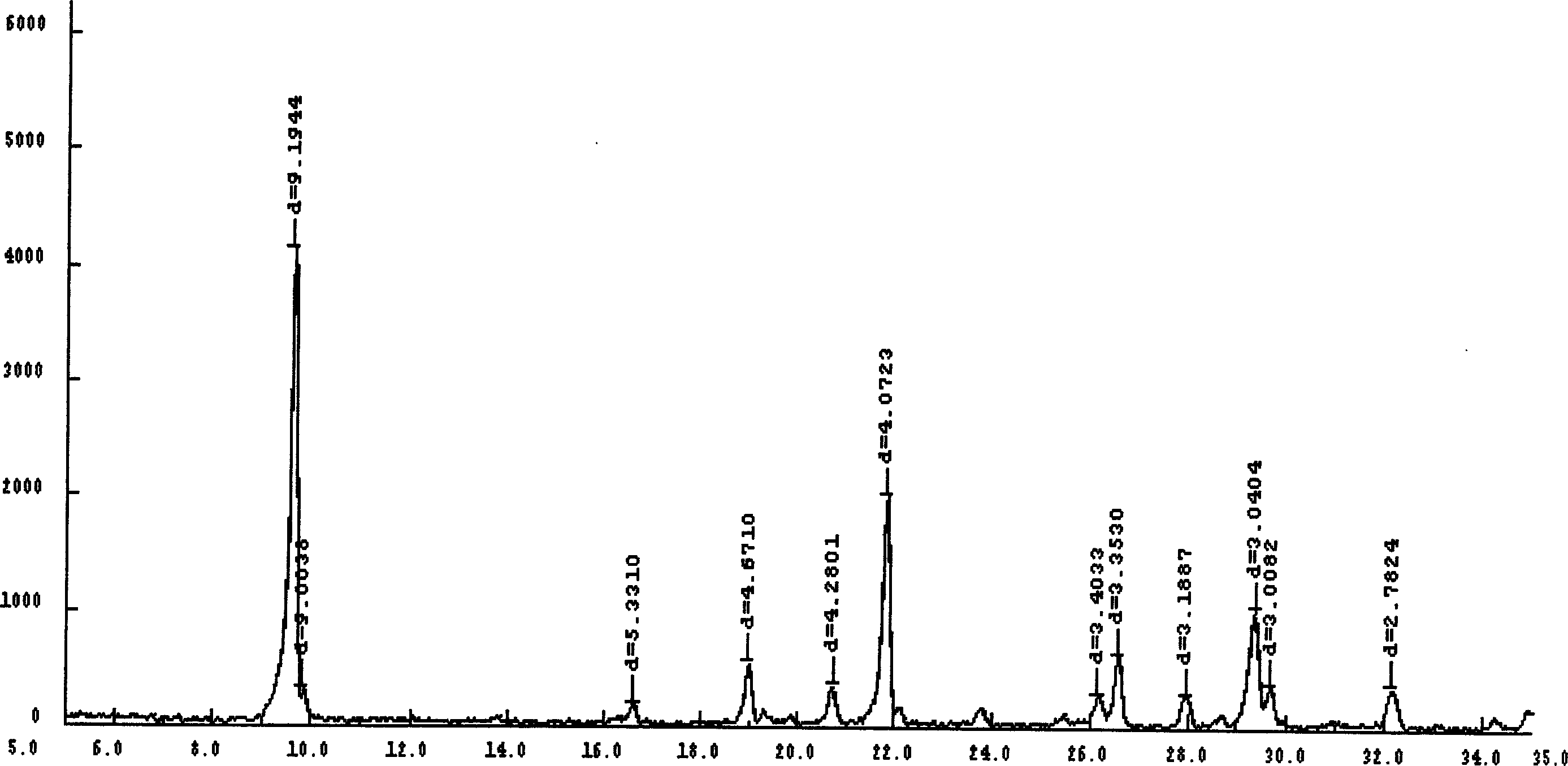

[0033] For the zeolite after the above-mentioned ammonium or acid exchange, use 0.01~1.5mol·dm -3 Left and right silver nitrate or silver acetate solution at room temperature ~ 110°C, space velocity 0.5 ~ 6hr -1 conditions, exchange for 5 to 48 hours to make it fully loaded with silver, and then the in-situ silver-loaded natural zeolite deiodination adsorbent can be made. See Table 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com