Nickel-iron smelting process from nickel oxide ore containing crystal water through blast furnace

A technology of blast furnace smelting and nickel oxide ore, which is applied in the field of blast furnace smelting technology, can solve the problems of nickel-chromium-containing hot metal that cannot flow out smoothly, large one-time investment, and serious environmental pollution, so as to avoid hearth burn-through, save energy, and process The effect of short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

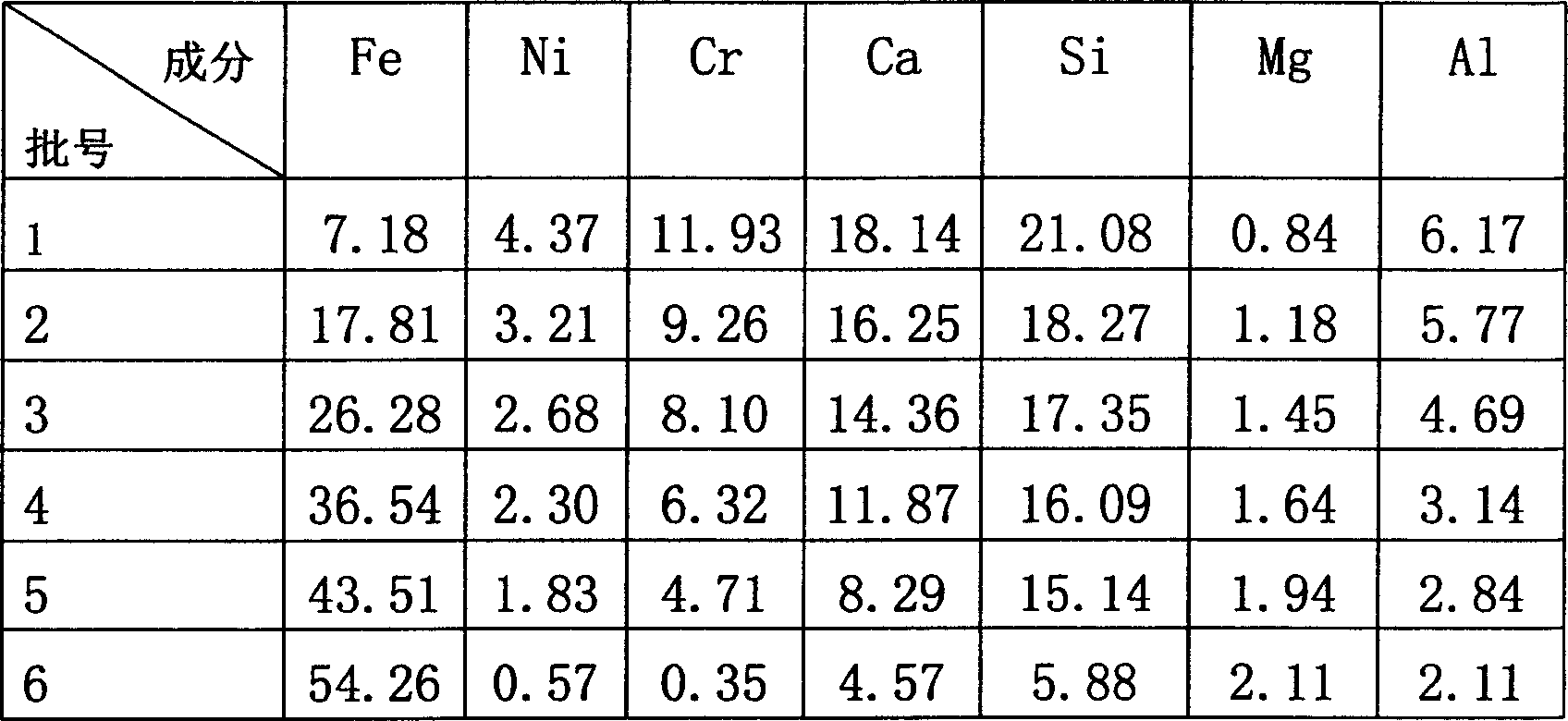

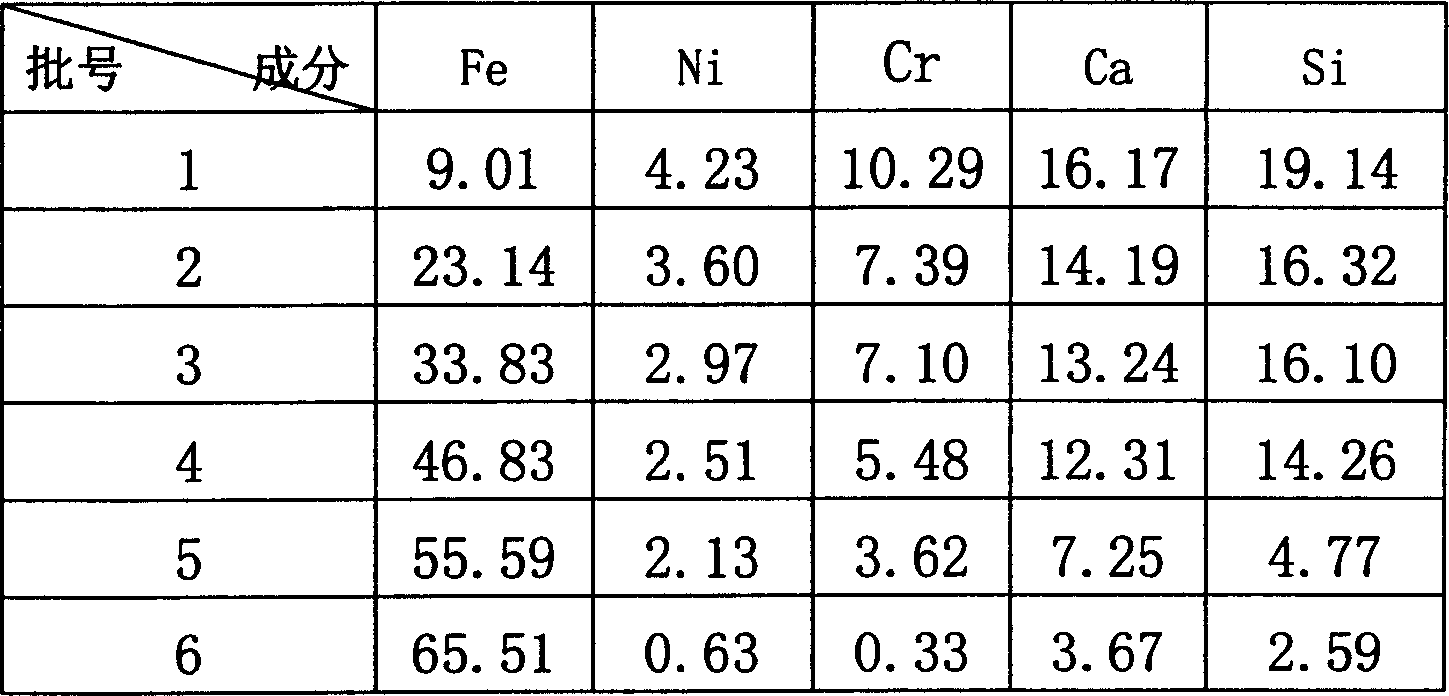

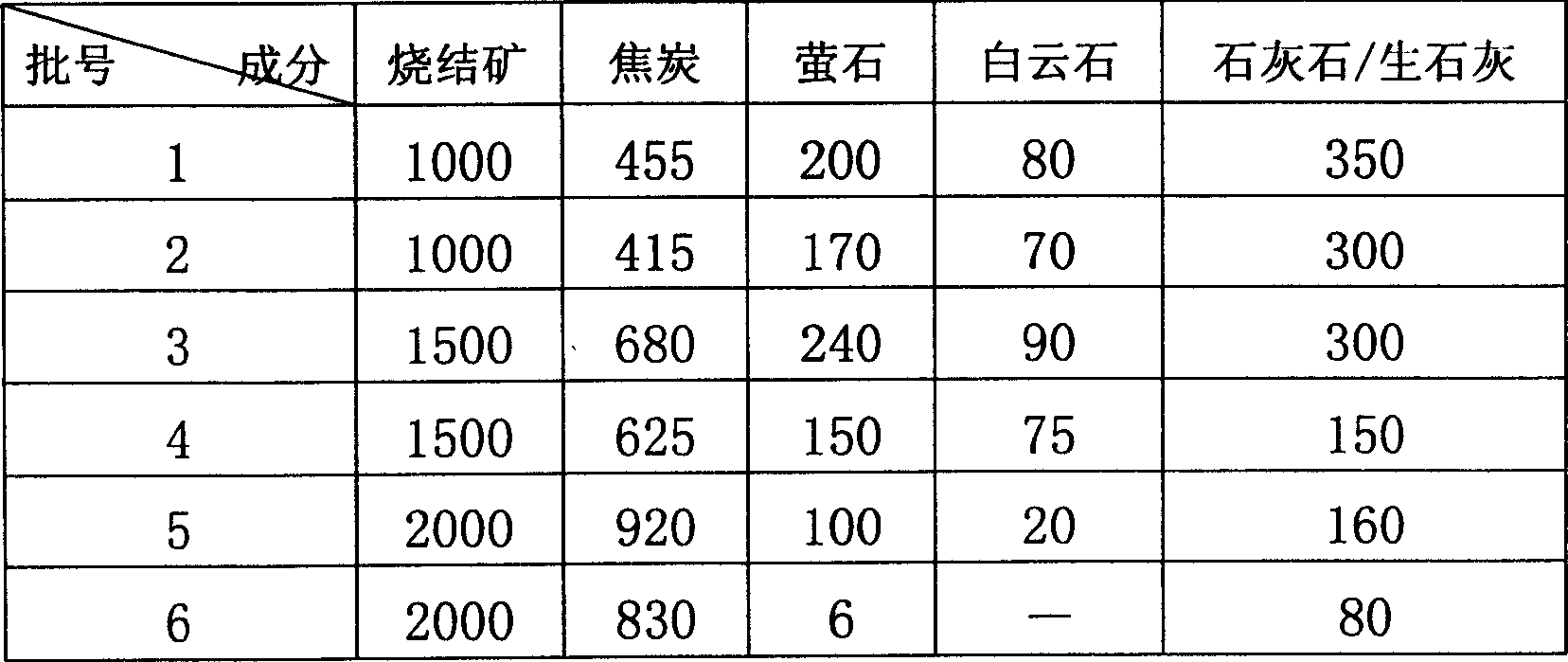

Examples

Embodiment Construction

[0026] The present invention will be further explained in conjunction with specific examples below. The following examples do not limit the scope of protection of the present invention, and all modifications and adjustments made based on the ideas of the present invention belong to the scope of protection of the present invention.

[0027] In the embodiment, the raw ore is selected from nickel-chromite imported from Albania.

[0028] The raw ore is crushed and screened, and the ore powder with a particle size of less than 2mm is mixed with coke powder and quicklime / limestone for sintering to obtain sintered ore nuggets;

[0029] Crush the sintered ore block obtained from the primary sintering, and then sieve through a 300-500-mesh sieve, and then perform magnetic separation to obtain the concentrate powder;

[0030] Sintering the concentrate powder, coke powder, and quicklime / limestone to obtain sintered ore nuggets;

[0031] Mix and smelt sintered ore nuggets with a particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com