Air admission and fuel supplying system for gas engine

A technology of fuel supply system and gas engine, applied in charging system, engine components, combustion engine, etc., can solve problems such as difficulty in starting, backfire, misfire, etc., and achieve good technical performance indicators, good comprehensive performance, and high thermal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

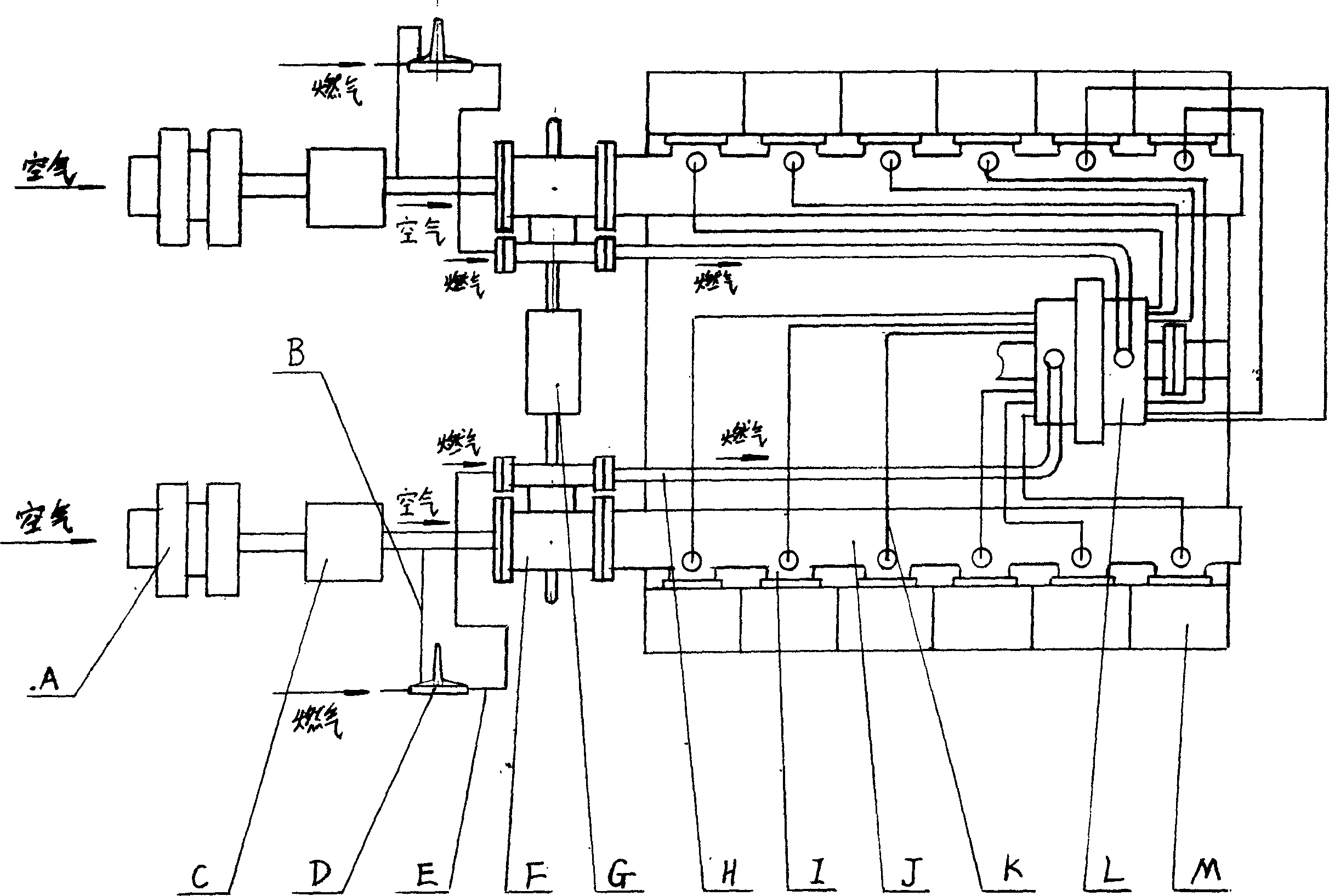

[0041] The specific implementation of the present invention for the 12V135 supercharged intercooler model is as follows:

[0042] The prototype diesel engine of this model is a 12V double-exhaust cylinder with a V-shaped angle of 75°. The two rows of intake pipes are arranged in the V-shaped angle. within the V-shaped angle.

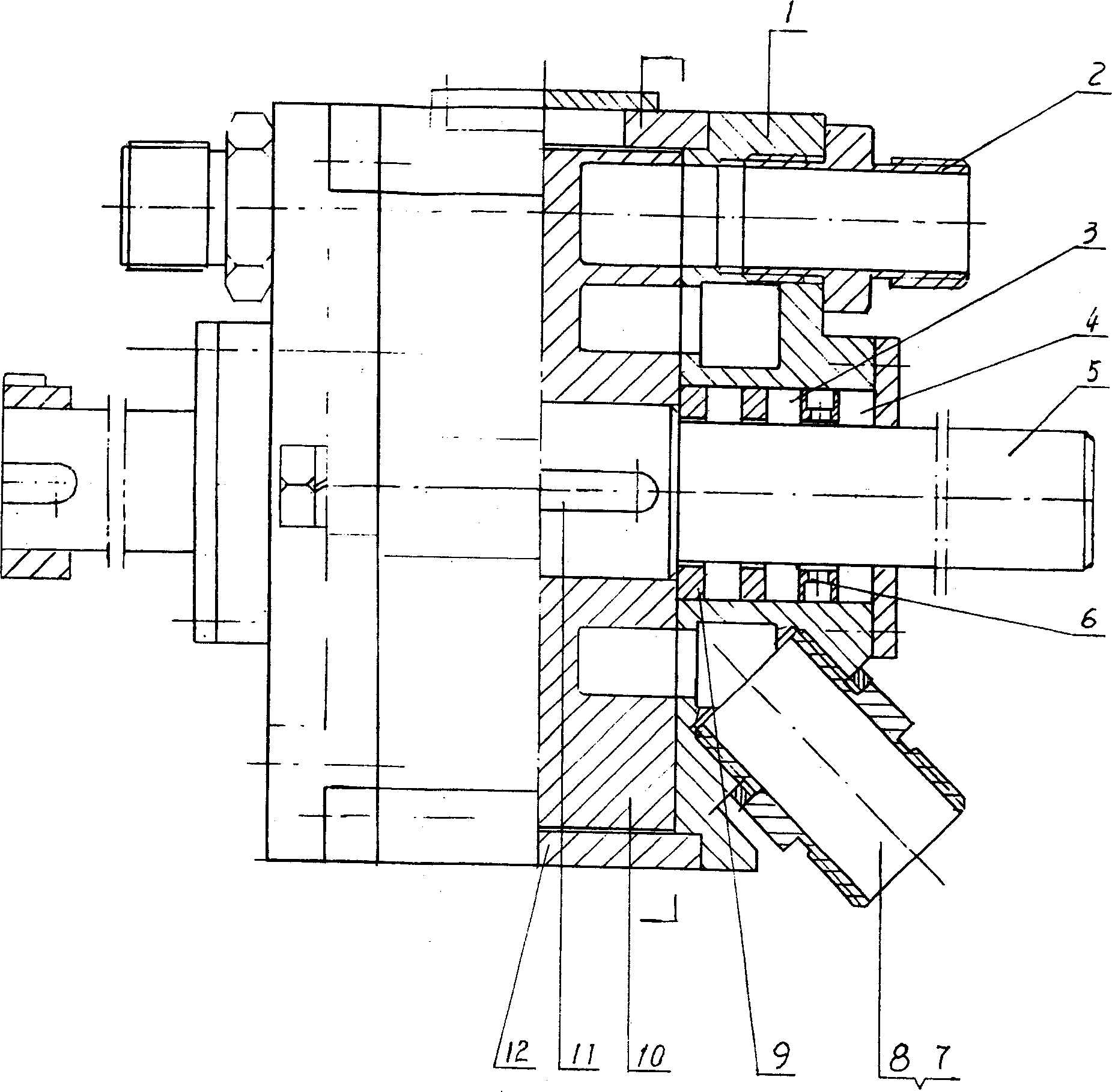

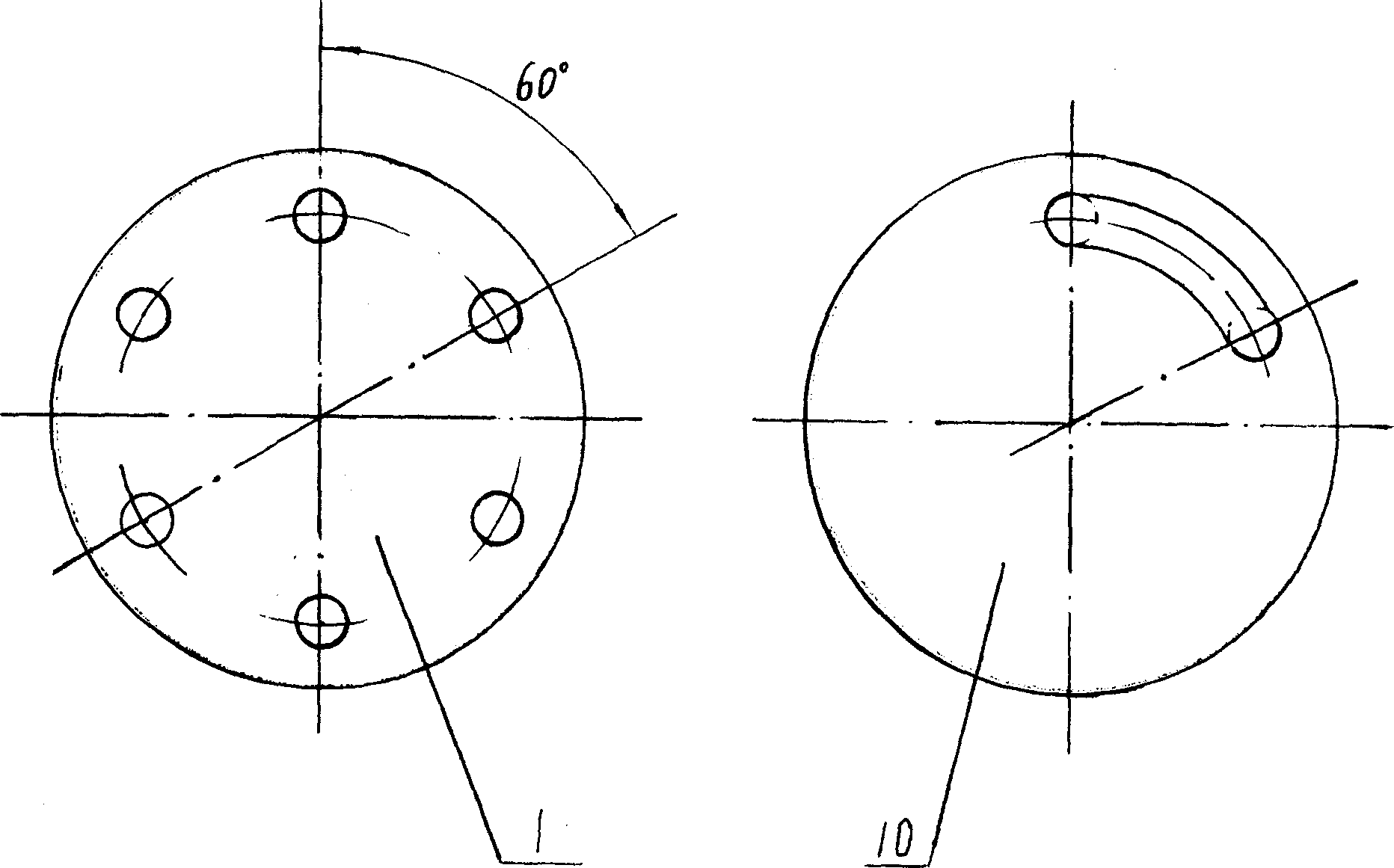

[0043] The general arrangement of the present invention for this model is as follows: figure 1 As shown, the connection relationship of each part is as follows: the air-fuel ratio controller F is two symmetrical, installed symmetrically on the two intake manifolds, and the middle is driven by the governor G; the air inlet of the air-fuel ratio controller F is connected to the The intercooler C of the supercharger A is connected; the air outlet is connected to the end face of the intake manifold J; the gas inlet is connected to the gas pressure regulator D through the gas manifold E in front of the controller; the gas outlet passes through the gas outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com