Water treatment materials and production thereof

A production method and new material technology, applied in the direction of adsorption of water/sewage treatment, clay products, other household appliances, etc., can solve the problems of difficult recycling, environmental pollution, waste of resources, etc., to save water treatment costs, good effect, Realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

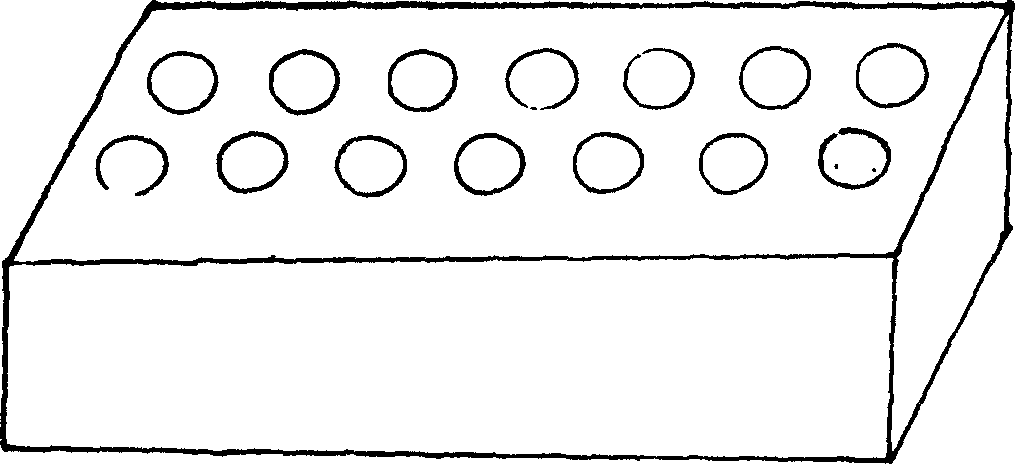

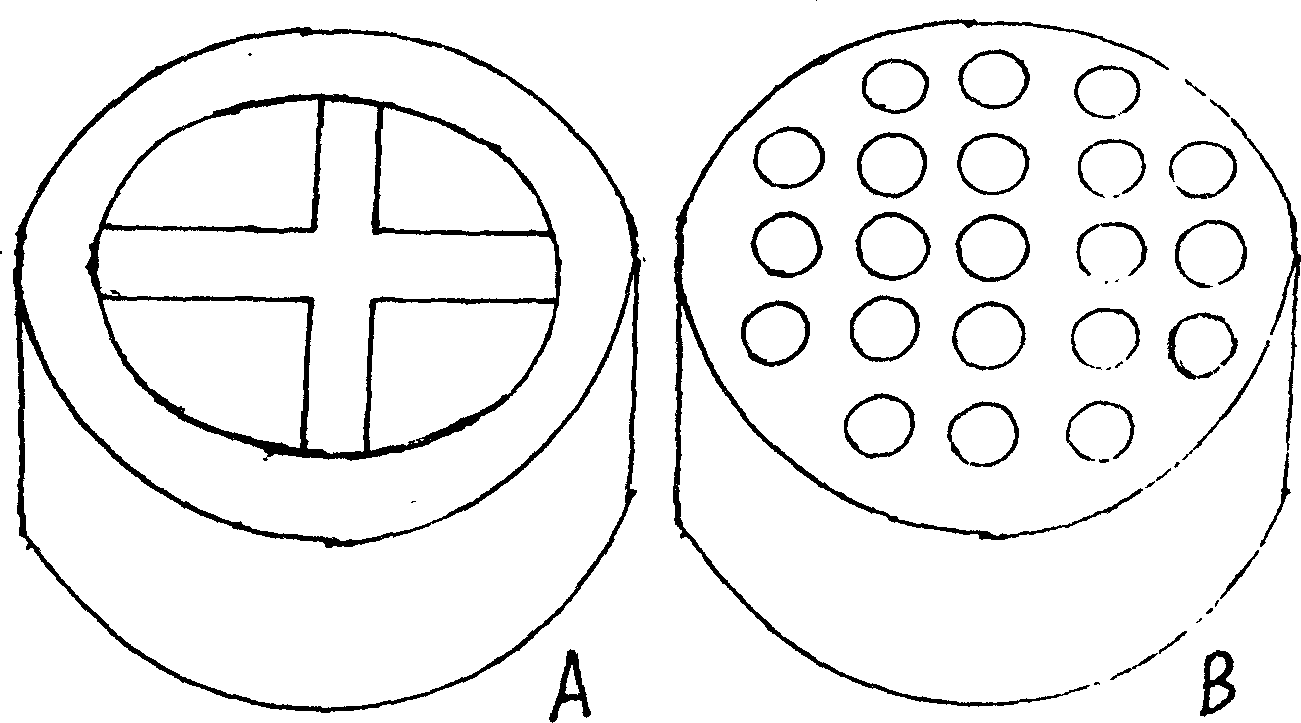

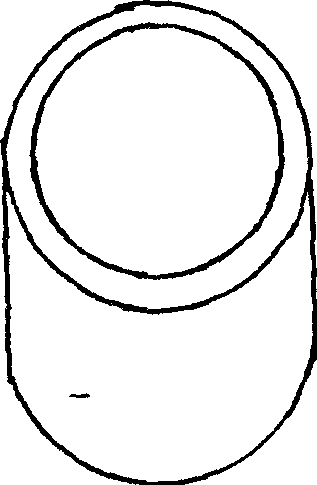

[0018] Take 700 kg of modified attapulgite clay and 300 kg of 20um-250um cinder, mix them evenly, and then add an appropriate amount of water to stir. The cylindrical mold that is provided with a plurality of columns in the mold is formed, and the solid after demolding is a cylinder (such as figure 2 As shown), vertical to the upper and lower planes of the cylinder, there are many holes that coincide with the pillars in the mold; the cylinder is air-dried and dehydrated and then baked in the furnace. When the temperature is slowly raised to 1000 ° C, the roasting is stopped. This process takes about four hours. , wait for it to cool down to room temperature naturally, spray the surface of the cylinder with an appropriate amount of beneficial microbial preparation mainly based on bacillus, so far the production of the present invention is completed, and the finished product is packed with a moisture-proof and anti-bacteria packaging Stored in reserve.

[0019] The material of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com