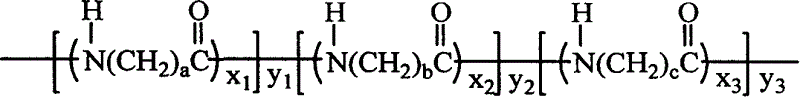

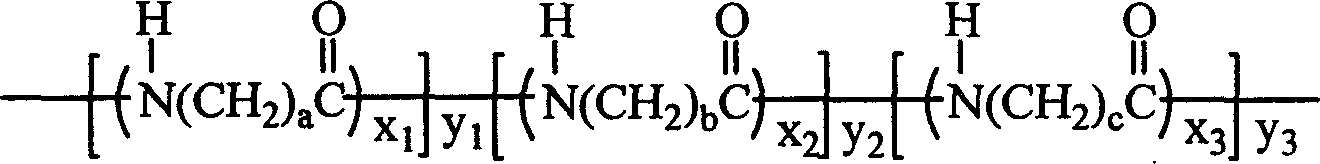

Block copolyamide and preparation thereof

A technology of copolyamide and block copolymer, which is applied in the field of block copolyamide and its preparation, can solve the problems of high cost, low-temperature resilience and poor flexibility of nylon resin, and achieve improved performance, reduced cost, and sufficient and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

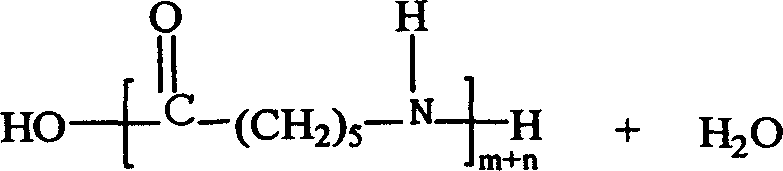

[0024] Preparation of block copolymerized PA611:

[0025] Using caprolactam (PA6) as raw material, adding monomer and 5-50wt% (calculated by monomer weight) deionized water into a stirring autoclave, the amount of feed to the polymerization tank does not exceed 2 / 3 of the volume of the tank. Replace the air in the polymerization kettle with nitrogen for 4-5 times, heat it, and keep the reactant under the condition of self-generated pressure for 2 hours when the temperature reaches 190°C, exhaust and depressurize to ambient pressure, heat to 220°C and vacuum for 60 Minutes, according to the actual viscosity of the reaction product, fill it with nitrogen and discharge it, cool it in a water tank, and cut it into pellets to obtain a PA6 prepolymer.

[0026] For the treatment of PA6 prepolymer, since the caprolactam monomer is soluble in water, boiling water can be used to remove the unreacted caprolactam monomer, that is, put the product into a certain amount of water, boil it, k...

Embodiment 2

[0053] Preparation of block copolymerized PA11 / 12:

[0054] With 11-aminoundecanoic acid (PA11), 12-aminododecanoic acid (PA12) and deionized water as raw materials, with a stirring autoclave of 10L, the polymerization of the oligomer can be carried out smoothly according to the preparation process of Example 1 Implementation, the proportioning of the prepolymer in the block copolyamide, the polymerization conditions and the process are the same as in Example 1.

[0055] The molecular weight of the prepolymer and the physical properties of the obtained block copolymerized PA11 / 12 are shown in Table 3.

[0056] table 3

[0057]

[0058] Polymerization vacuum (MPa)

Embodiment 3

[0060] Preparation of block copolymerized PA6 / 11 / 12:

[0061] With caprolactam (PA6), 11-aminoundecanoic acid (PA11), 12-aminododecanoic acid 9 (PA12) and deionized water as raw materials, with a 10L agitated autoclave, the polymerization of oligomers is according to the examples The preparation process of 1 can be implemented smoothly, the polymerization conditions and process of the block copolyamide are the same as in Example 1, and the proportioning ratio of the prepolymer in the block copolyamide is shown in Table 4.

[0062] Table 4

[0063]

[0064] The physical properties of the obtained block copolymerized PA6 / 11 / 12 and the molecular weight of the prepolymer are shown in Table 5.

[0065] table 5

[0066]

[0067] Intrinsic viscosity η r

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com