Polymorphic indium tin oxide thin-membrane and production of polymorphic indium tin oxide electrode

A technology of indium tin oxide and a manufacturing method, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of increased cost, difficult control of film uniformity, reduced competitiveness of manufacturers, and the like, Achieve the effect of improving yield, shortening processing time, and optimizing film properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

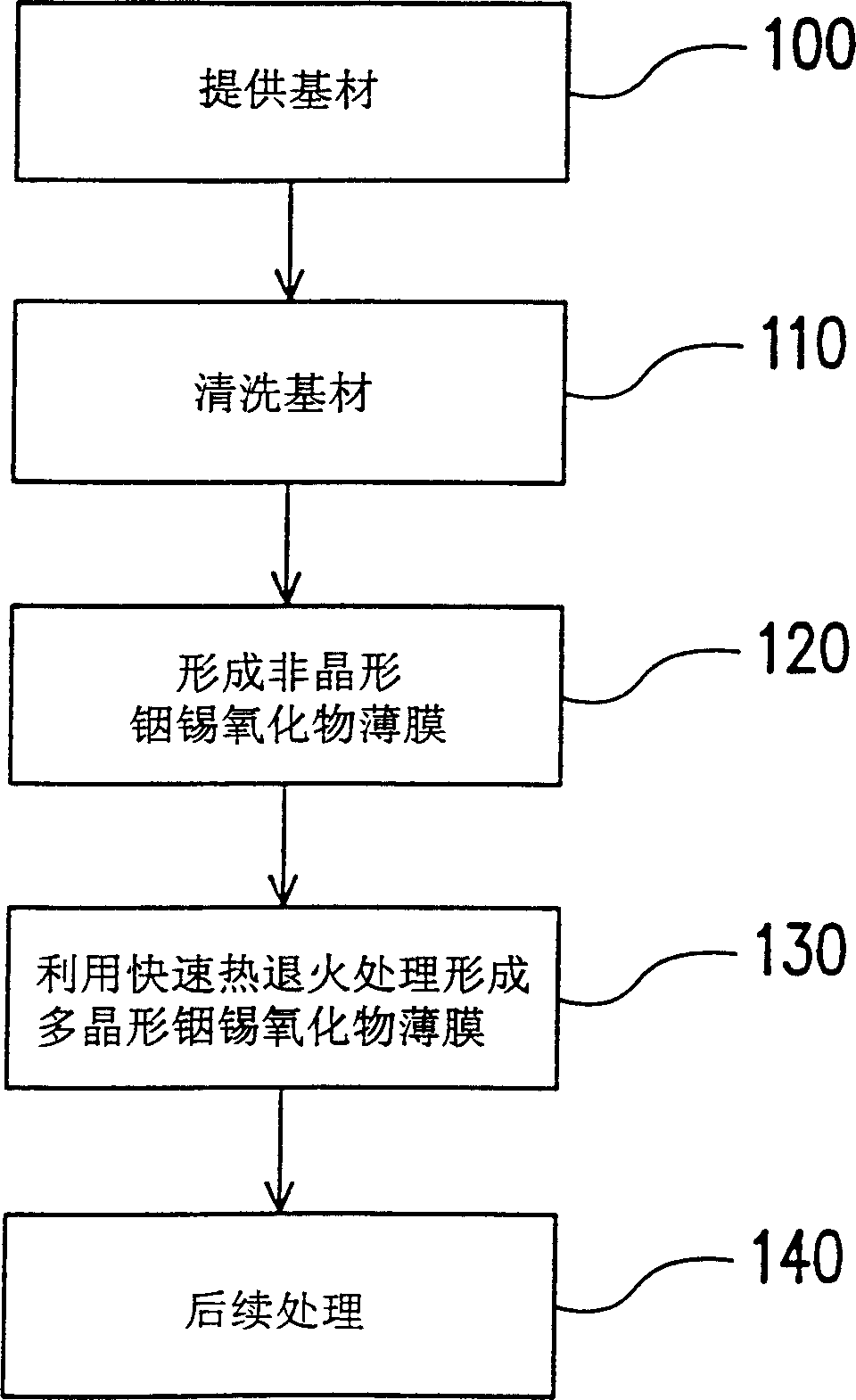

[0064] figure 1 It is a schematic flow chart of a manufacturing method of a polycrystalline indium tin oxide thin film in a preferred embodiment of the present invention, Figure 2A to Figure 2D It is a schematic cross-sectional flow diagram of a polycrystalline indium tin oxide film manufacturing method in a preferred embodiment of the present invention.

[0065] Such as figure 1 as well as Figure 2AAs shown, a substrate 210 is firstly provided (step 100 ), and before forming an ITO film, the substrate 210 is cleaned (step 110 ) to remove pollutants or particles on the substrate 210 . In this embodiment, the substrate 210 is, for example, a glass substrate, a silicon substrate, a plastic substrate, or other hard or soft substrates.

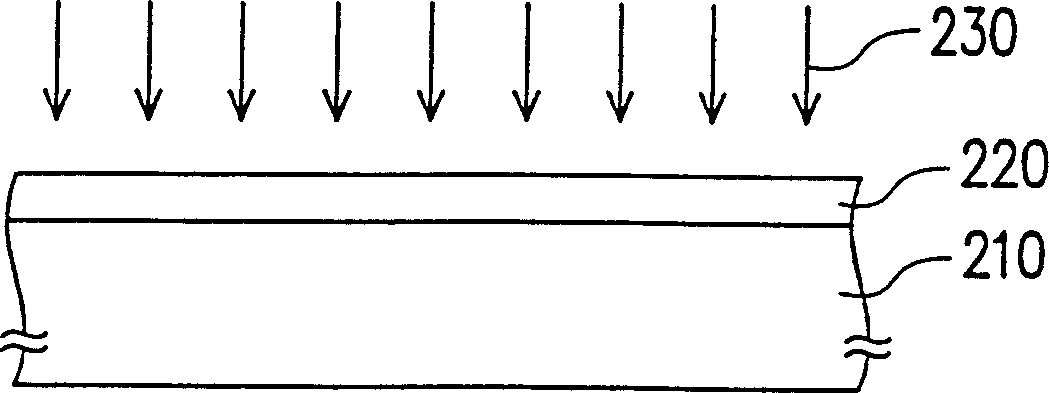

[0066] Next, if figure 1 as well as Figure 2B As shown, an amorphous ITO film 220 is formed on a substrate 210 (step 120). The method for forming the amorphous indium tin oxide film is, for example, physical vapor deposition or chemical v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com