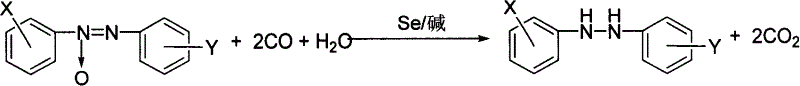

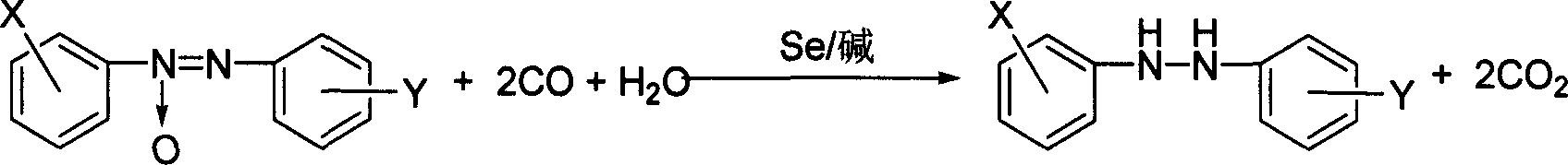

Method for synthesizing hydrogenated azo compounds

A technology for hydrogenating azo and compounds, which is applied in organic chemistry, hydrazine preparation, etc., can solve the problems of high cost and the reduction of azo oxide groups that have not been seen yet, and achieve the effects of low cost, easy subsequent separation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add azobenzene oxide 9.8g (50mmol), Se 0.08 (1mmol), H 2 O 9g (0.5mol), triethylamine 0.5g (5mmol) and solvent DMF 200mL, continue to pass through carbon monoxide, and heat to 88 ° C and stir for 0.5 hours, cool to room temperature, switch carbon monoxide to oxygen or air and stir for 0.5-1 hour Finally, filter out the selenium powder. The solvent was evaporated by distillation under reduced pressure (below 5kPa), washed with water, and filtered. The yield was 95%.

Embodiment 2

[0023] temperature(℃)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com