Method for preparing borate-based crystal and laser oscillation apparatus

A manufacturing method, borate technology, applied in the field of cesium-boric acid used in laser oscillators, can solve the problems of high cost and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Cesium-borate-based crystals are produced using one embodiment of the method for producing borate-based crystals of the present invention.

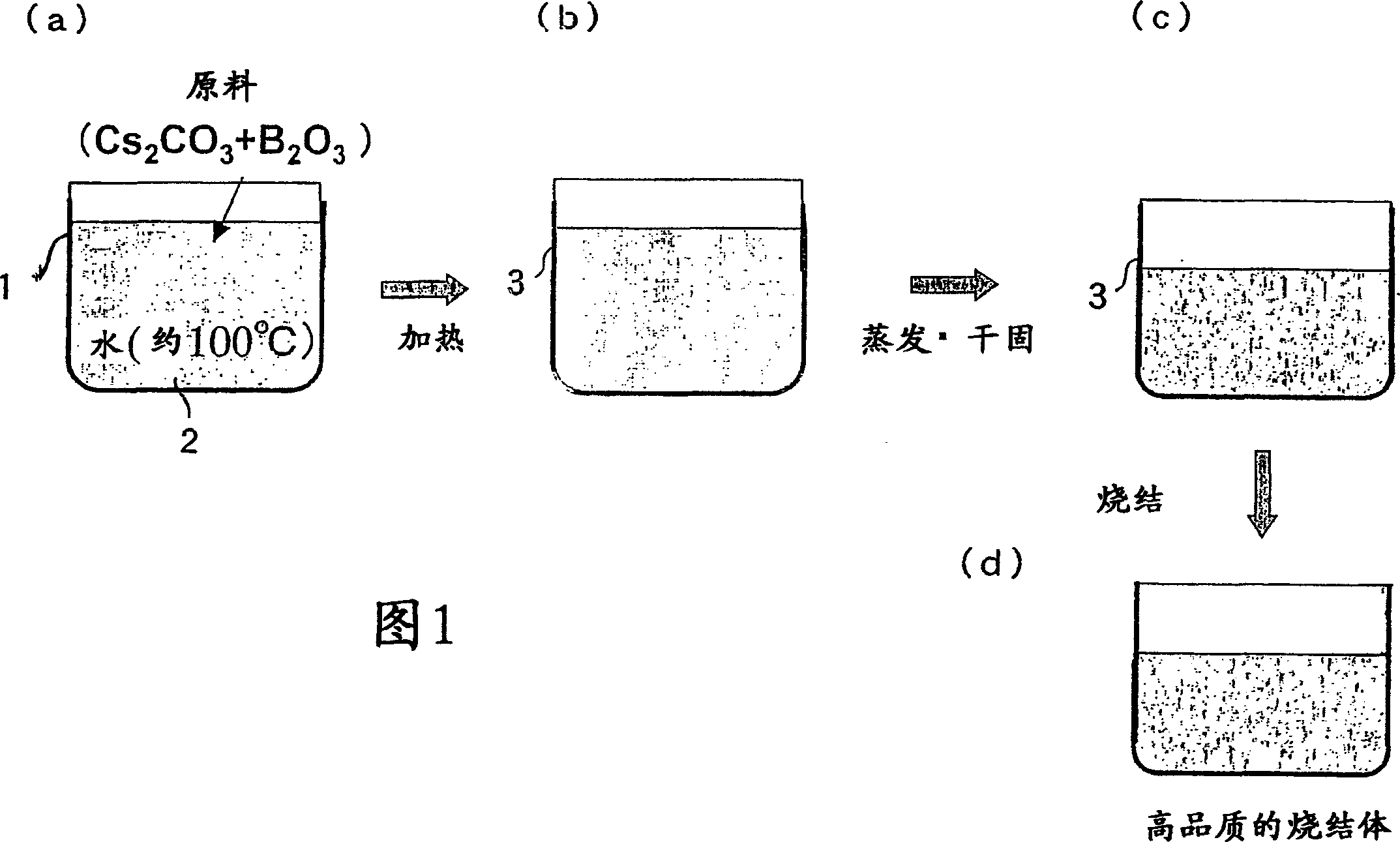

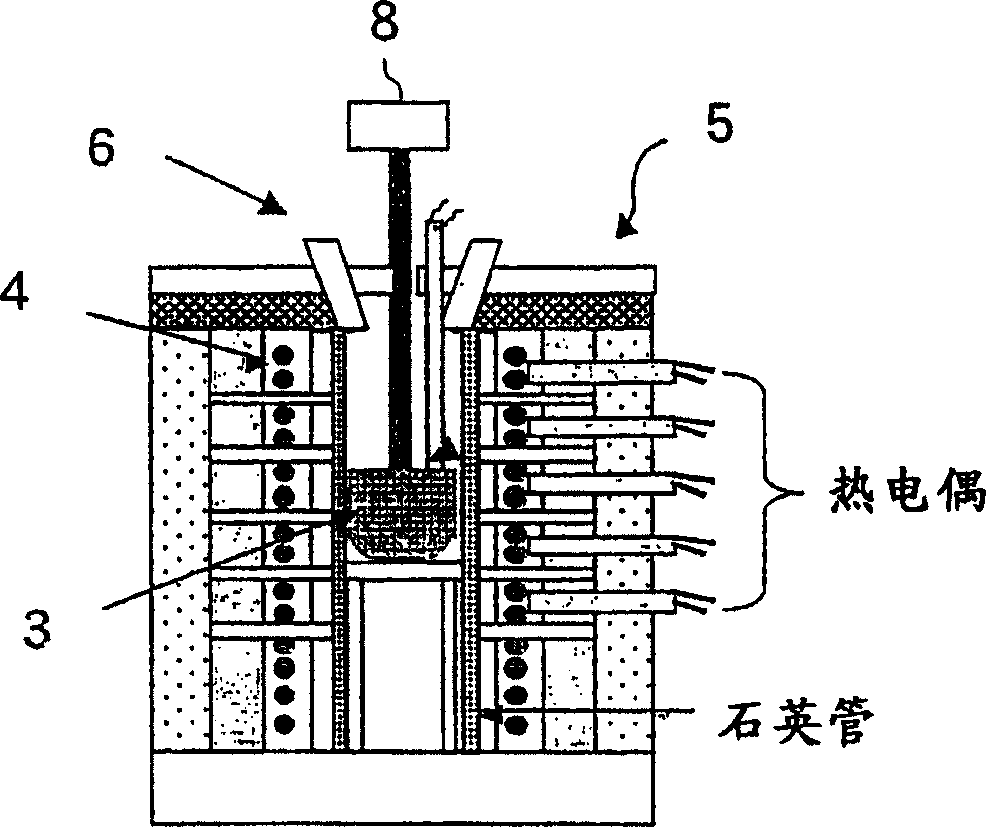

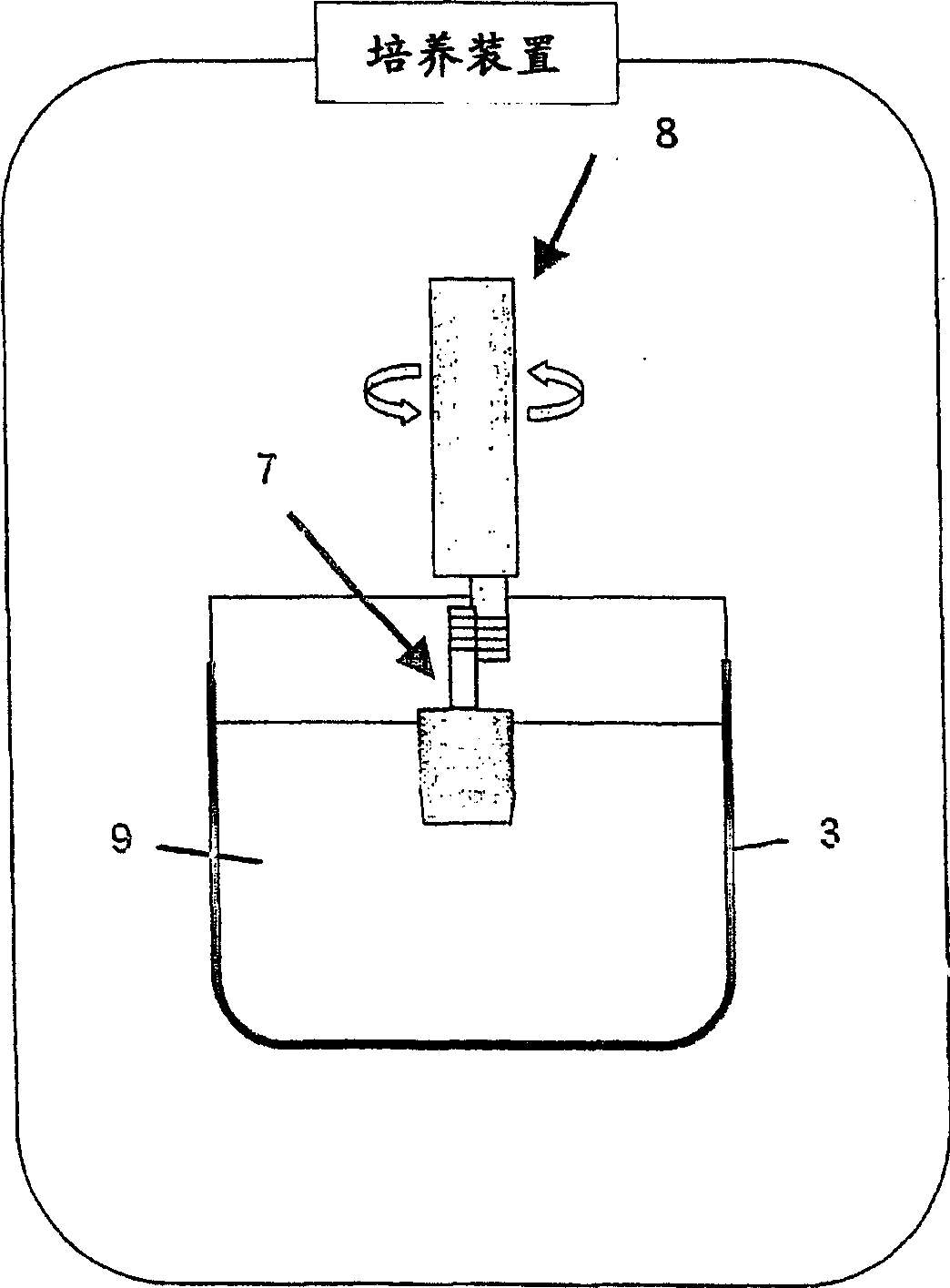

[0095] First, as shown in Figure 1(a)-(d), add ion-exchanged water (2) into a container (1) made of polymethylpentene with a diameter of 20 cm and a height of 26 cm, and heat it to about 100 ° C in a melting furnace. Add 4337.4g Cs to it 2 CO 3 with 2162.6g B 2 o 3 The homogeneously mixed mixture dissolves, and heating is continued to evaporate the water. After the water is evaporated, the remaining material is filled into an open platinum crucible (3) with a diameter of 15 cm x a height of 15 cm, heated to 300° C. to dry, and then heated to 650° C. to bake to make the culture material. Then put the crucible (3) into the figure 2 In the five-layer controlled cylindrical resistance heating furnace (5) for cultivating the heater (4) shown, the small hole (6) for crystal seed entry and exit is provided at a position corresponding...

Embodiment 2

[0099] Cesium-borate-based crystals were produced using conditions different from those in Example 1 of the method for producing borate-based crystals of the present invention, and the properties of the cesium-borate-based crystals were evaluated as nonlinear optical crystals.

[0100] As shown in Figure 1, add ion-exchanged water (2) into a container (1) made of polymethylpentene with a diameter of 20 cm x a height of 26 cm, heat it to about 100 ° C in a dissolution furnace, and add 4671.1 g of Cs to it. 2 CO 3 with 2328.9g B 2 o 3 Mix the mixture evenly to dissolve it, and continue heating to evaporate the water.

[0101] After the water is evaporated, the remaining materials are filled in an open platinum crucible (3) with a diameter of 15 cm x a height of 15 cm, heated to 300° C. to dry, and then heated to 650° C. for sintering. Carry out the XRD measurement of this culture raw material, the result is as follows Figure 4 The peak shown in (b) can be confirmed to be on...

Embodiment 3

[0108] In the past CLBO crystallization culture, the amount of raw material was about 6kg, and expansion was caused by decarboxylation during heating, so Cs was not carried out. 2 CO 3 , Li 2 CO 3 , B 2 o 3 The powder is mixed and fired to fill a platinum crucible, and the temperature is raised to 900°C to melt or incubate the solution. In this case, during the heating process, the B with the lowest melting point among the raw materials 2 o 3 Melted first, it is estimated that Cs was dissolved in it 2 CO 3 with Li 2 CO 3 . That is, when melting raw materials in a heterogeneously mixed state, the high-viscosity boric acid-based raw materials are unlikely to cause diffusion, and it is estimated that regions with high concentrations of Cs and Li are locally generated, and it becomes difficult to form the necessary CLBO composition and structure during crystal growth.

[0109] In addition, a test of precipitating a CLBO crystal phase by sintering the raw material was al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com