Photocatalytic membrane and its preparation process

A photocatalytic film and carrier technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as degradation and destruction of carrier adhesives, and achieve good photocatalysis without high temperature burning. The effect of active, good sustained photocatalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

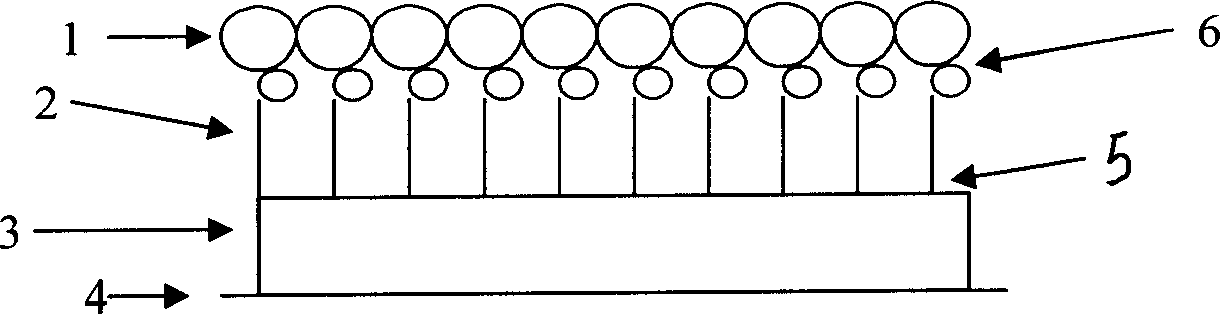

[0021] Embodiment 1: Take stainless steel net as carrier, coat polyurethane paint on stainless steel net; Before paint is dry, coat silane coupling agent DMC, WD-10, WD-30, WD-50, WD-60 or WD-80 (purchase from Wuhan University chemical factory), leaves standstill in the air to the silane coupling agent solidification of material surface; With anatase type, particle diameter is the TiO of 25 nanometers 2 Disperse in industrial alcohol to form a 20wt% suspension or sol, coat the suspension or sol on the silane coupling agent, and dry it under an infrared lamp to obtain a photocatalytic film.

[0022] Silane coupling

Embodiment 2

[0023] Embodiment 2: take copper net as carrier, coat polyester paint on copper net, coat silane coupling DMC, WD-10, WD-30, WD-50, WD-60 or WD-80 (from Wuhan University chemical factory purchase), in the air to stand still to the silane coupling agent solidification of material surface; TiO with anatase type, particle diameter is 25 nanometers 2 Disperse in industrial alcohol to form a 20wt% suspension or sol, coat the suspension or sol on the silane coupling agent, and dry it under an infrared lamp to obtain a photocatalytic film.

[0024] A silane coupling agent

Embodiment 3

[0025] Embodiment 3: take plastic net as carrier, coat polyurethane paint on plastic net; Coupling silane coupling agent WD-60, WD-10, DMC (purchase from Wuhan University chemical plant) on it, leave standstill in the air The silane coupling agent on the surface of the material is solidified, and the crystal form is dominated by anatase phase, mixed with about 20wt% rutile phase, and TiO with a particle size of 10 nanometers 2 Disperse in an aqueous solution of isobutanol with a volume concentration of 80% to form a 25wt% suspension or sol, coat the suspension or sol on a silane coupling agent, and dry it under an infrared lamp to obtain a photocatalyst membrane.

[0026] A silane coupling agent

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com