Polycinnamic alcohol production formula and its preparation process

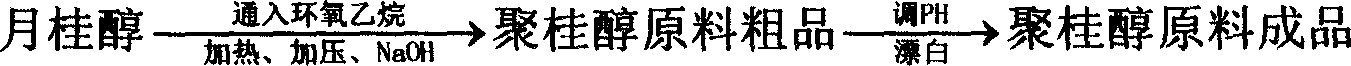

A preparation process, lauromacrogol technology, applied in the field of lauromacrogol production prescription and its preparation process, can solve the problems that have not been reported, and achieve the effect of simplifying the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In the reaction of synthetic lauromacrogol bulk drug,

[0054] 1. Specifications and standards of chemical raw materials:

[0055] lauryl alcohol chemically pure

[0056] Ethylene oxide chemically pure

[0057] Solid Sodium Hydroxide Chemically Pure

[0058] Acetic acid chemically pure

[0059] 2. Preparation route and related technical parameters:

[0060]

[0061] Feed Ratio Molecular Ratio Lauryl Alcohol: Ethylene Oxide = 1:9

[0062] Weight ratio lauryl alcohol: ethylene oxide = 1: 1.95 ~ 2.13 parts

[0063] The consumption of catalyzer solid sodium hydroxide: 0.1% (W / W, according to total feeding amount)

[0064] Namely: 0.00295~0.00313 copies

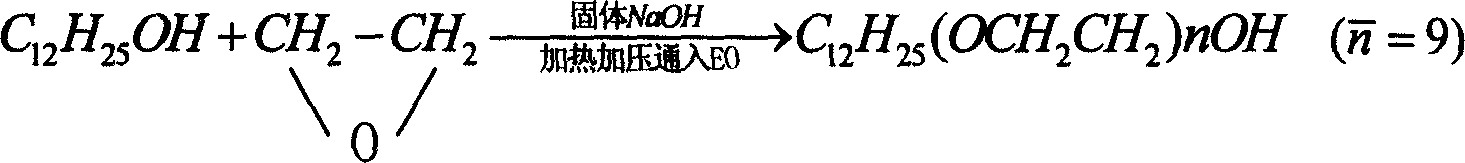

[0065] 3. Detailed chemical reaction formula and reaction conditions

[0066]

[0067] Heating, raising the temperature to 135-150°C, feeding ethylene oxide

[0068] The pressure is kept at 0.15~0.20MPa

[0069] The temperature is controlled at 140~155℃

[0070] Reacti...

Embodiment 2

[0092] In the reaction of synthetic lauromacrogol bulk drug,

[0093] 1. Specifications and standards of chemical raw materials:

[0094] lauryl alcohol chemically pure

[0095] Ethylene oxide chemically pure

[0096] Solid Sodium Hydroxide Chemically Pure

[0097] Acetic acid chemically pure

[0098] 2. Preparation route and related technical parameters:

[0099]

[0100] Feed Ratio Molecular Ratio Lauryl Alcohol: Ethylene Oxide = 1:9

[0101] Weight ratio lauryl alcohol: ethylene oxide = 1:2 parts

[0102] The consumption of catalyzer solid sodium hydroxide: 0.1% (W / W, according to total feeding amount)

[0103] That is: 0.003 copies

[0104] 3. Detailed chemical reaction formula and reaction conditions

[0105]

[0106] Heating, raising the temperature to 135°C, feeding ethylene oxide

[0107] The pressure is maintained at 0.18MPa

[0108] Temperature controlled at 150°C

[0109] Reaction end point control Reactant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com