Potash feldspar wet method decomposition and production process

A production process and technology of potassium feldspar, applied in potash fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of product and by-product output and quality to be improved, ore decomposition is not thorough enough, silicon-containing gas recovery is complex, etc., to achieve economic benefits Appreciable, easy-to-control, well-set-up effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

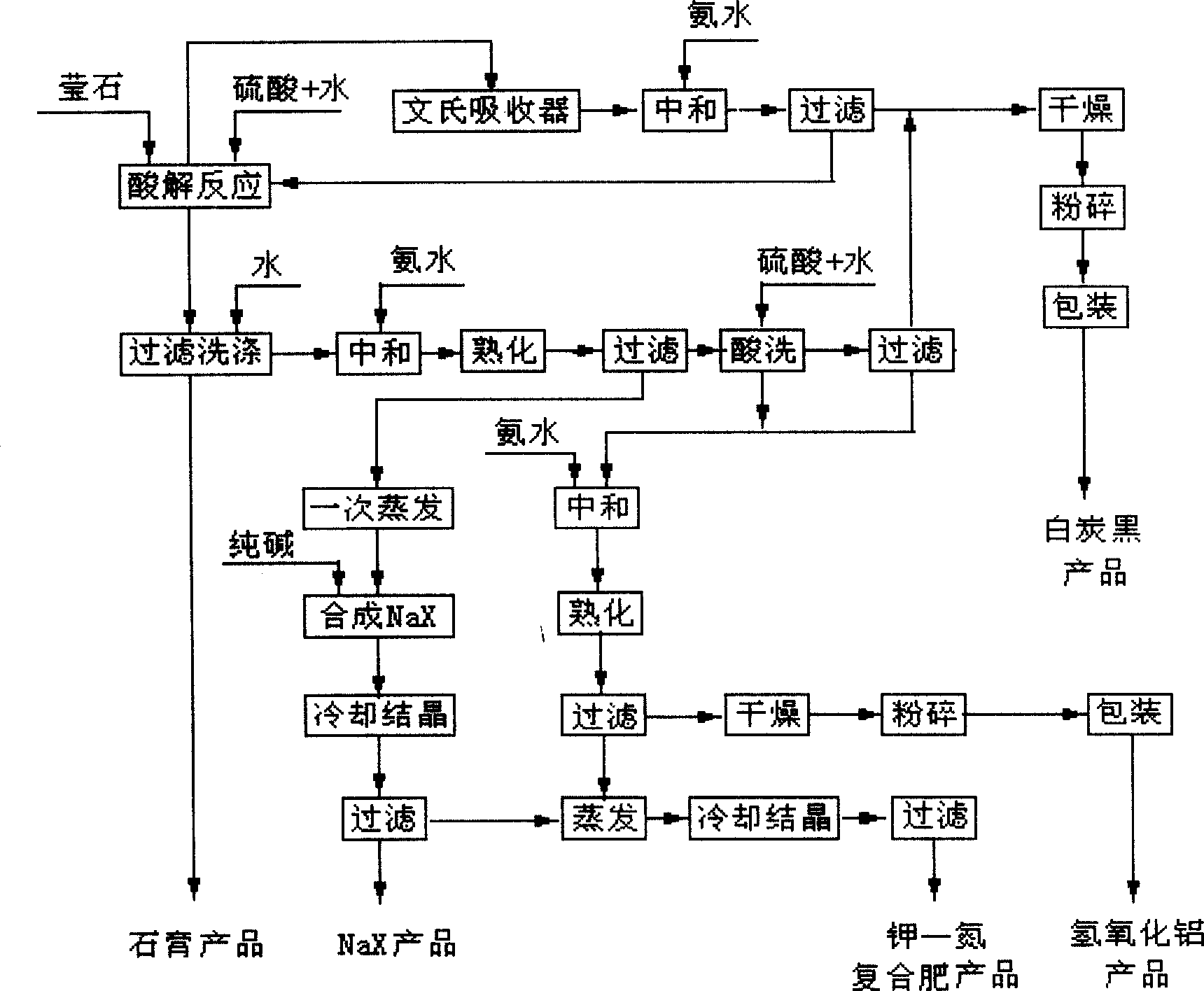

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment:

[0023] 1. Pretreatment of ore

[0024] Potassium feldspar has a very tight lattice structure and very stable chemical properties. In the implementation process, the local flesh-red potassium feldspar ore was selected as the main raw material, and the K in the ore 2 The average content of O is more than 10.5%, SiO 2 The average content is 66%, Al 2 o 3 The average content is 15%, Fe 2 o 3 The average content is in the range of 3%-4%. Potassium feldspar ore should be kept dry and should not be placed in the open air to prevent water from being brought in and affecting crushing. The ore should be coarsely crushed and ball milled to 150-200 mesh (full sieve). 200-mesh ore powder can be used as raw material to increase the contact area with acid and other substances. Since the ore contains Fe 2 o 3 , FeO and other impurities with darke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com