Preparation method of inorganic glass reinforced plastic framework material and agricultural green house thereof

A technology of inorganic glass fiber reinforced plastics and greenhouse skeletons, applied in botany equipment and methods, greenhouse cultivation, climate change adaptation, etc., can solve the problems of poor thermal insulation, high cost, short service life, etc., to facilitate disassembly and transfer, and save land resources , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] (1), 80 gram ferrous sulfates are joined in the magnesium chloride aqueous solution of 22.5 kilograms 17 Baume degree, stir 5-7 minute;

[0030] (2), add 700 grams of lignin again, stir 5 minutes;

[0031] (3), add 900 grams of silicon dioxide subsequently, stir 5 minutes;

[0032] (4), add 200 grams of sodium pyrophosphate subsequently, stir 5 minutes;

[0033] (5), add 80 grams of oxalic acid subsequently, fully stir;

[0034] (6), 50 kilograms of magnesium oxides are joined in the mixture of the step (5) gained, stir 30 minutes;

[0035] (7), then molding in the mold;

[0036] (8), then curing for 45 minutes;

[0037] (9), then keep healthy in the health care room, the time of health care is 28 days, the temperature is 18-30 ℃, and keep the moist state.

example 2

[0039] (1), 90 gram ferrous sulfates are joined in the magnesium chloride aqueous solution of 22.5 kilograms 23 Baume degree, stir 5-7 minute;

[0040] (2), add 750 grams of lignin again, stir 5 minutes;

[0041] (3), add 1000 grams of silicon dioxide subsequently, stir 5 minutes;

[0042] (4), add 250 grams of sodium pyrophosphate subsequently, stir 5 minutes;

[0043] (5), add 100 grams of oxalic acid subsequently, fully stir;

[0044] (6), 50 kilograms of magnesium oxides are joined in the mixture of the step (5) gained, stir 30 minutes;

[0045] (7), then molding in the mold;

[0046] (8), then curing for 45 minutes;

[0047] (9), then keep healthy in the health care room, the time of health care is 28 days, the temperature is 18-30 ℃, and keep the moist state.

example 3

[0049] (1), 100 gram ferrous sulfates are joined in the magnesium chloride aqueous solution of 22.5 kilograms 27 Baume degree, stir 5-7 minute;

[0050] (2), add 800 grams of lignin again, stir 5 minutes;

[0051] (3), add 1100 grams of silicon dioxide subsequently, stir 5 minutes;

[0052] (4), add 300 grams of sodium pyrophosphate subsequently, stir 5 minutes;

[0053] (5), add 120 grams of oxalic acid subsequently, fully stir;

[0054] (6), 50 kilograms of magnesium oxides are joined in the mixture of the step (5) gained, stir 30 minutes;

[0055] (7), then molding in the mold;

[0056] (8), then curing for 45 minutes;

[0057] (9), then keep healthy in the health care room, the time of health care is 28 days, the temperature is 18-30 ℃, and keep the moist state.

[0058] The following are examples of agricultural greenhouses.

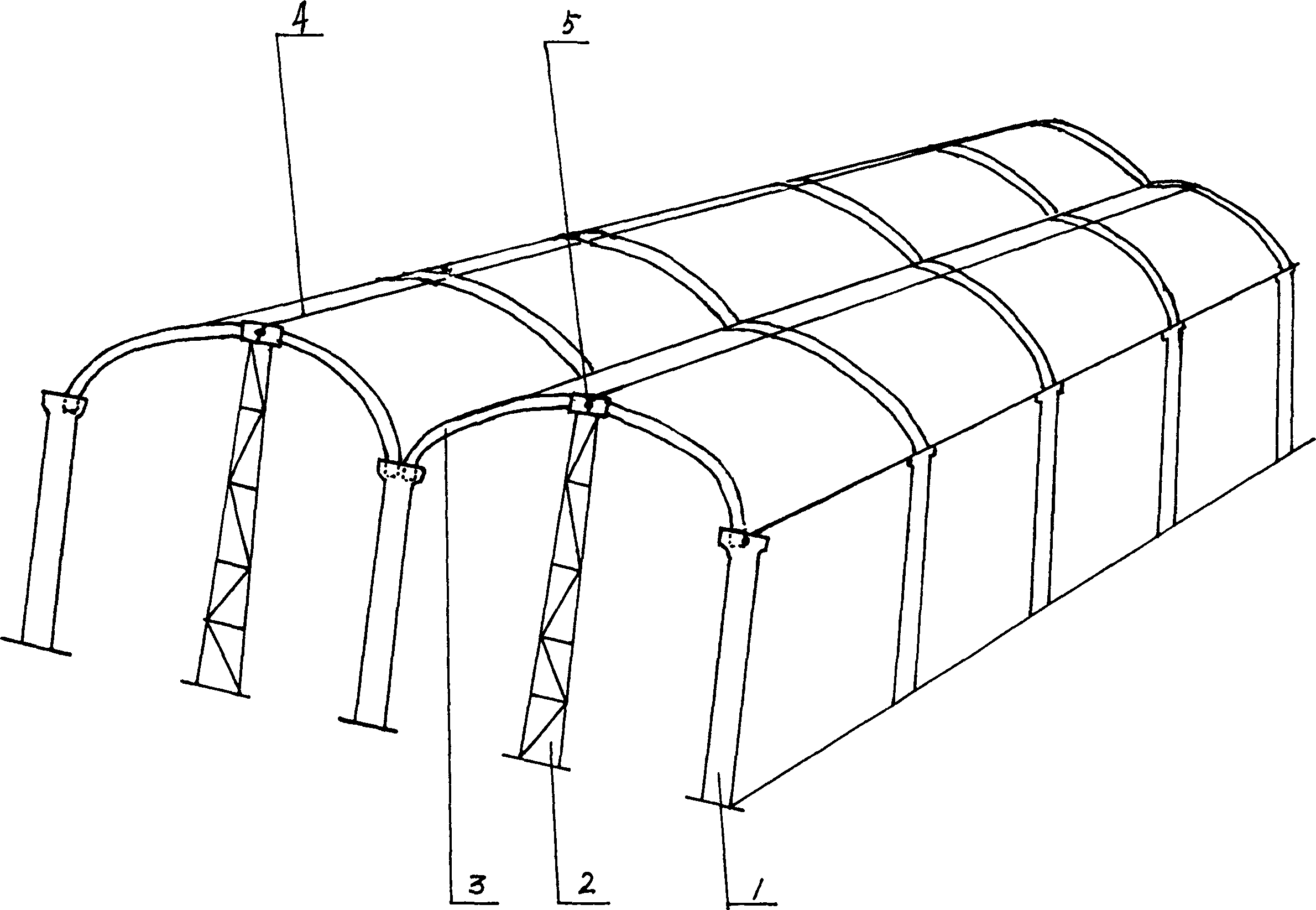

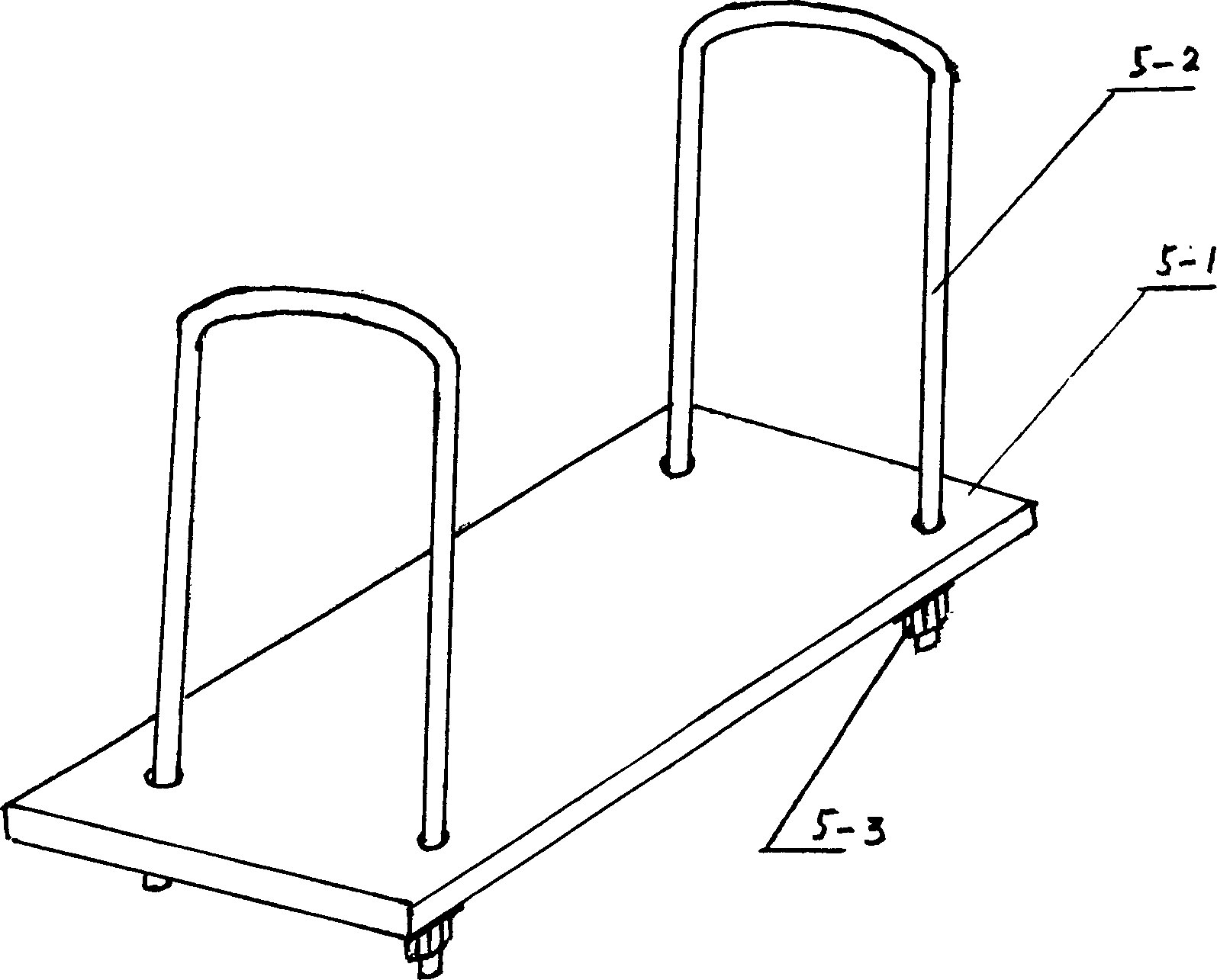

[0059] Such as figure 1 As shown, there are several rows of columns 1 in this embodiment, and the outer sides of the edge sheds are the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com