Bond pad structure

一种接合垫、合金的技术,应用在半导体/固态器件零部件、半导体器件、电气元件等方向,能够解决降低接合可靠性、接合垫间距与尺寸无法进一步缩小、失去与金层线连结等问题,达到增加可靠度、避免失效与接垫剥离的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

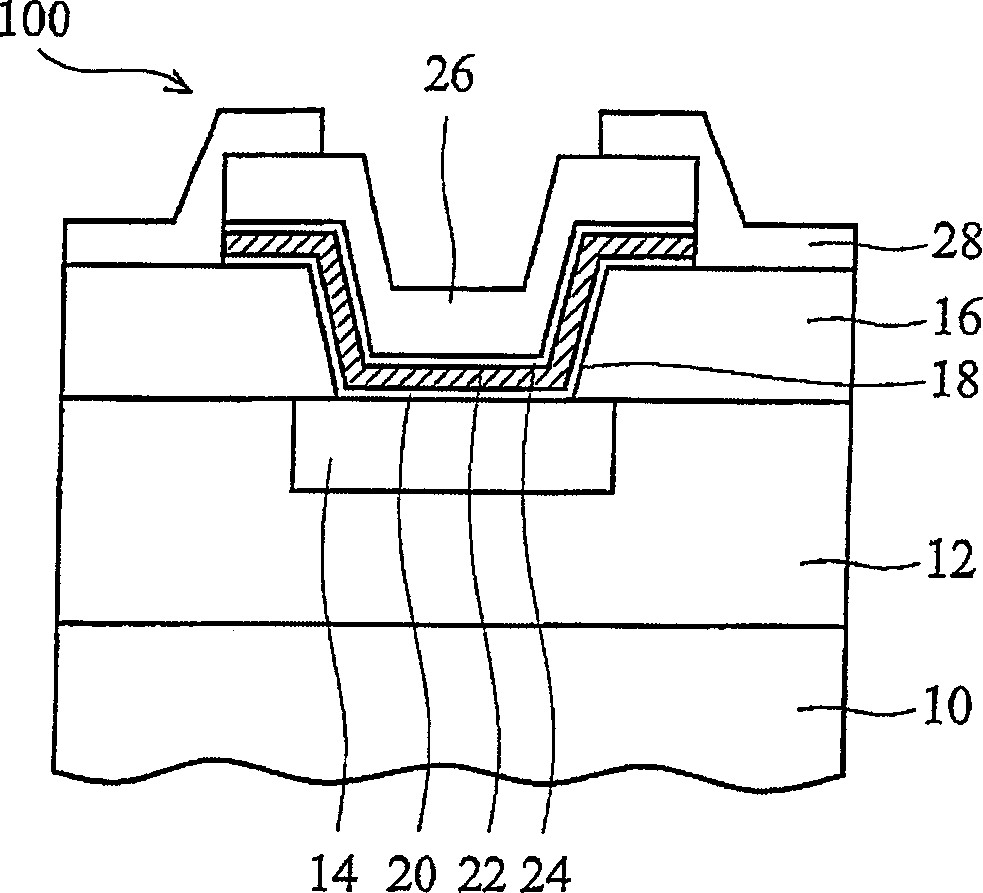

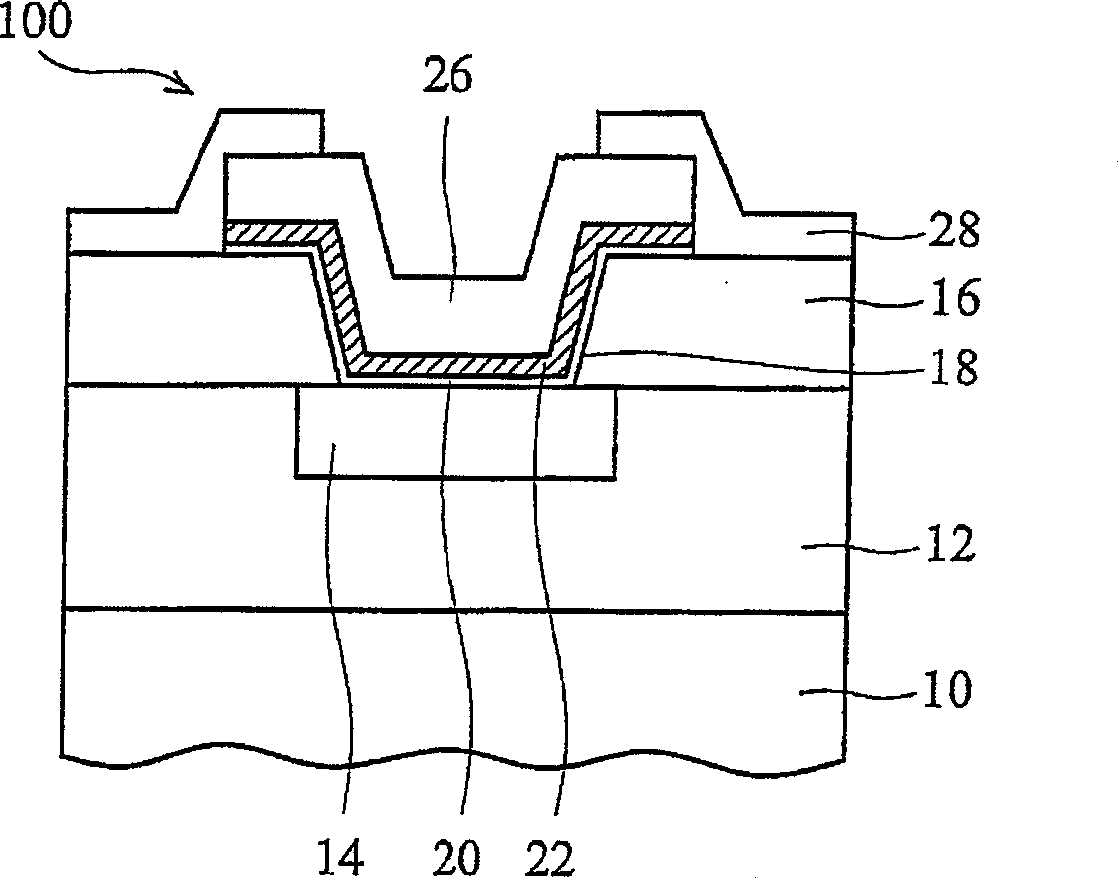

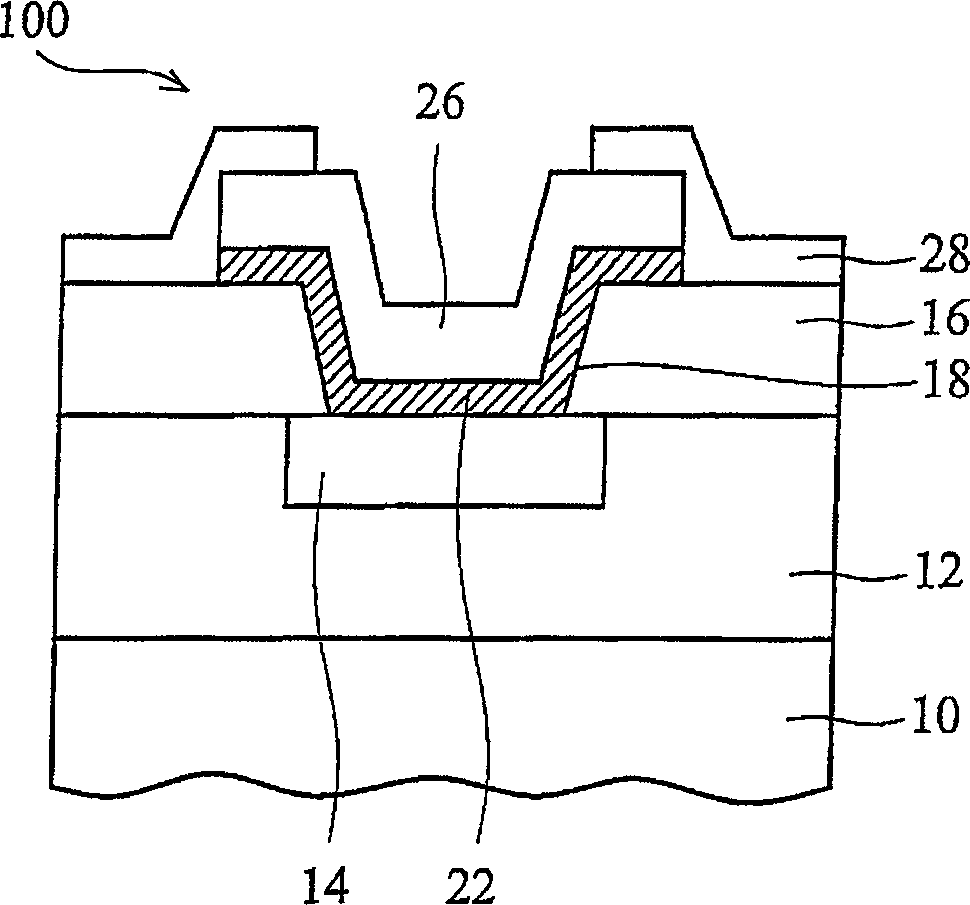

[0032]The present invention provides an improved bond pad structure for integrated circuits. One embodiment of the present invention provides a bonding pad structure, which has a stress buffer layer disposed between an uppermost interconnection metal layer and a bonding pad layer, so as to avoid damage caused by wafer electrical testing (such as wafer The probe test) and the damage caused by the stress of package impact (such as wire bonding, flip-chip packaging or other external forces in the packaging process). The stress buffer layer can be a conductive material, and compared with the material properties of one of the first metal layer and the bonding pad layer, Young's modulus, hardness, strength or toughness of the stress buffer layer (toughness) is larger. In one embodiment of the present invention, a bonding pad structure is provided on an integrated circuit chip having at least one low-k multilayer (dielectric constant substantially less than 3.9), which has a stress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com