Animal cell feeding culture process

A fed-batch culture, animal cell technology, applied in animal cells, fusion cells, cells modified by introducing foreign genetic material, etc., can solve the problems of divergence, long research cycle, process instability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

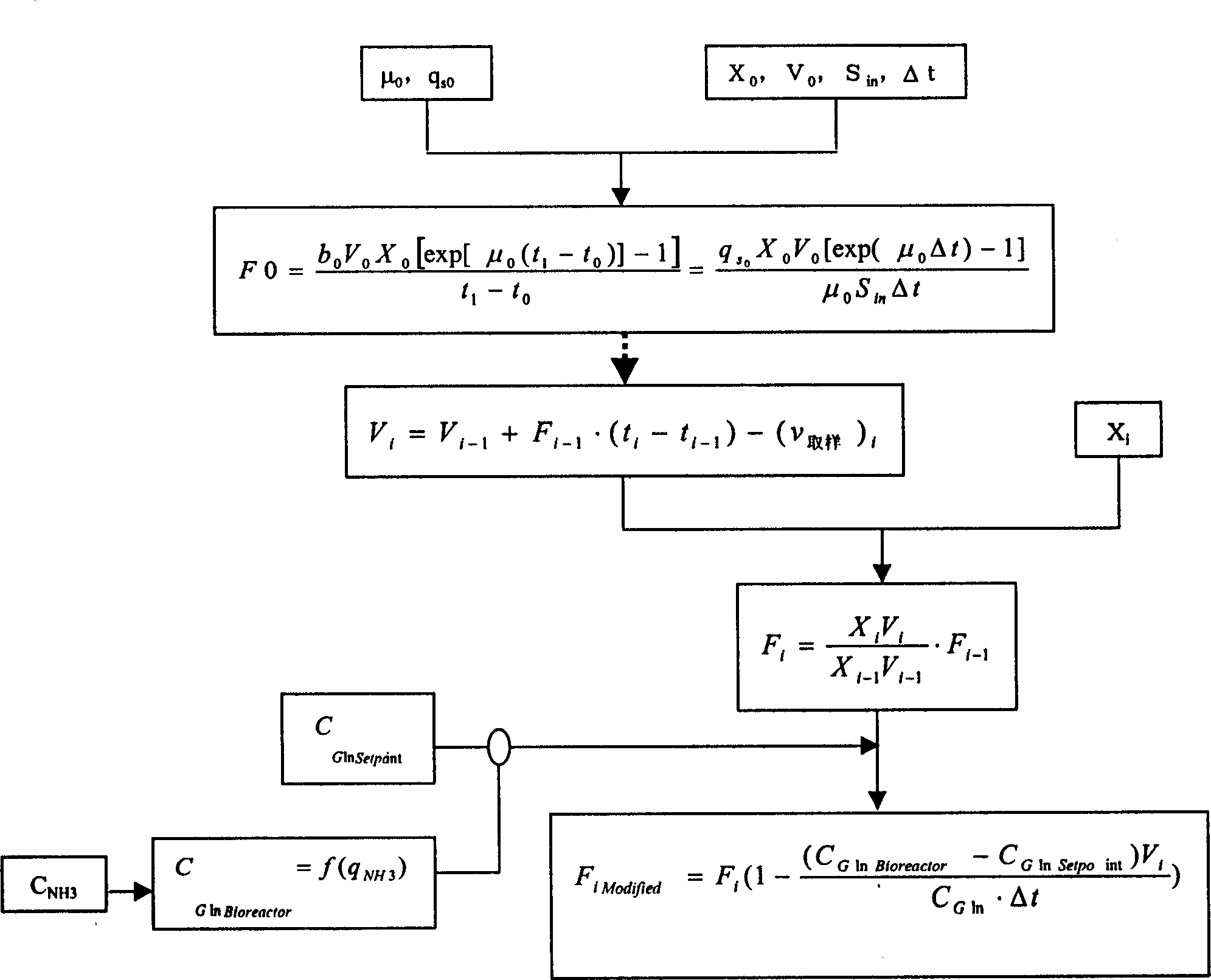

Method used

Image

Examples

Embodiment 1~2

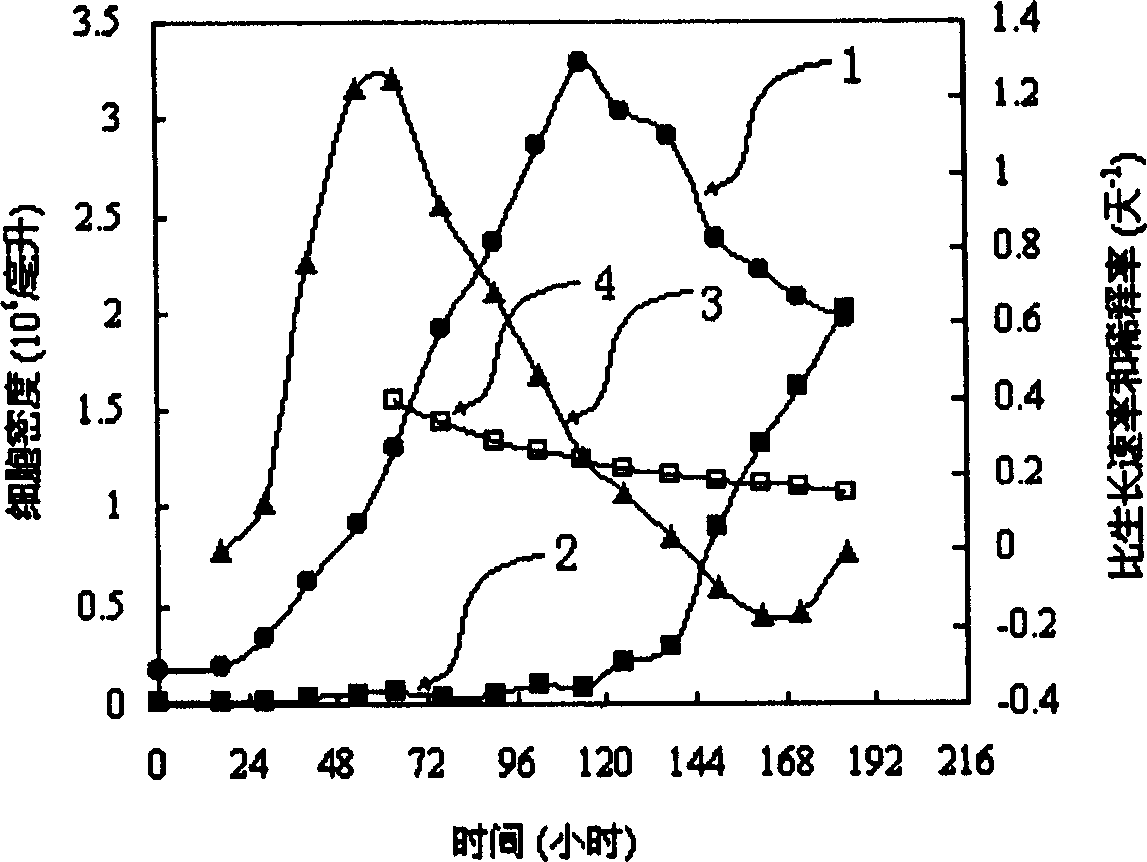

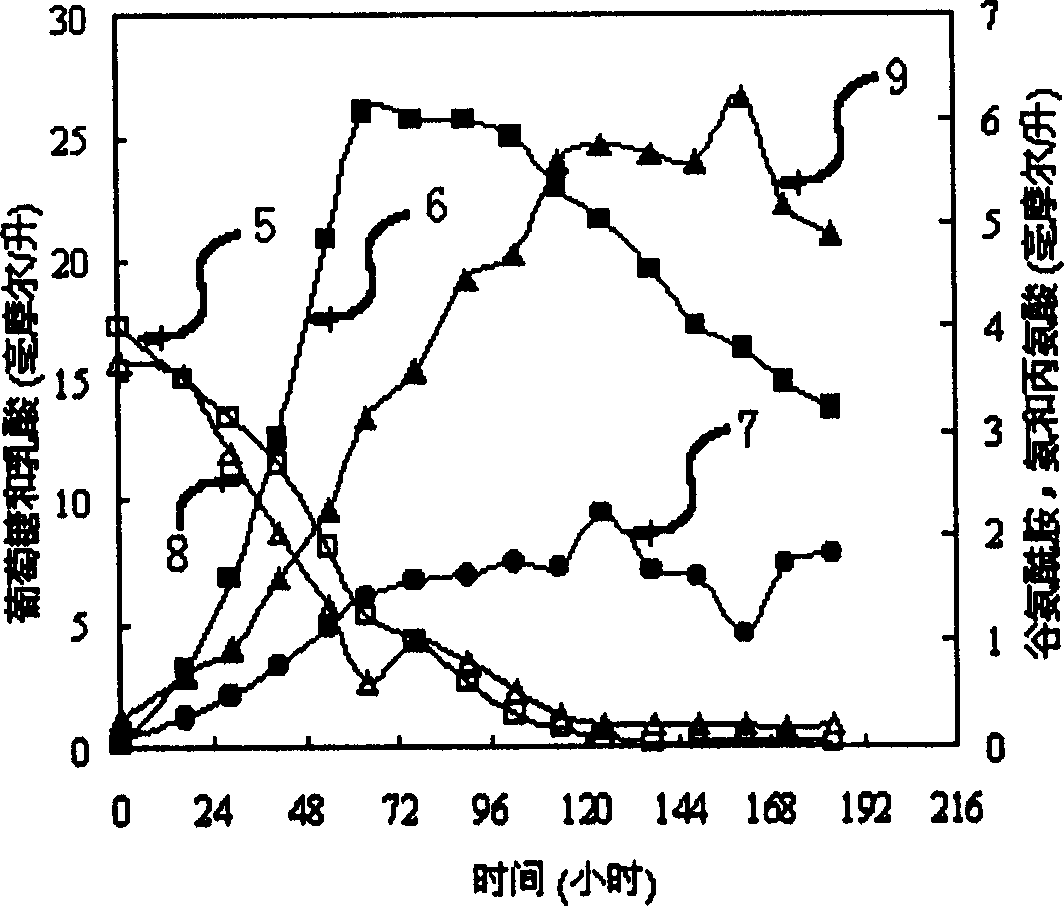

[0084] (a). Metabolism study

[0085] The physiological state of HB58 hybridoma cells (ATCC) under glucose-limited or glutamine-limited culture conditions is studied by using the method described in the present invention. Inoculate in Biostat B (Germany B.BRAUN company) 2 liters of bioreactors, inoculation density 2.0 * 10 5 cells / ml. When the living cell density reaches 1.0×10 6 Start fed-batch culture after cells / ml, the dilution rate is 0.30day -1 , the culture time was 125 hours and 100 hours respectively, achieving glucose limitation (see figure 2 and image 3 ) and glutamine-limited quasi-steady-state culture ( Figure 4 and Figure 5 ), can be used to study the metabolic rules when the cells are in the corresponding state. During the whole cultivation process, the stirring speed of the reactor was 120 rpm, the temperature was 36.8° C., and the dissolved oxygen was 50% air saturation.

[0086] Element

Inorganic salt (mg / L)

CaCl 2 ...

Embodiment 3~4

[0093] (b). High-density optimized fed-batch culture

[0094] HB58 hybridoma cells (ATCC) were optimized fed-batch culture by the method of the present invention. In a Biostat B (Germany B.BRAUN company) 2 liter bioreactor, the live cell seeding density was 2.0×10 5cells / ml. The concentrations of glucose and glutamine in the initial medium were 7.8mmol / L and 2.5mmol / L, respectively, and the concentrations of other amino acids were the original concentrations of DMEM / F12 (1:1) medium. When the viable cell density reaches 1.0×10 6 After cells / ml, start feeding medium exponentially based on cell demand. The feeding dilution rate is 0.30day -1 .

[0095] The concentrations of glucose and glutamine in fed-batch medium were 100mmol / L and 33mmol / L, respectively, and the amino acid was 6.5 times the mass of DMEM / F12 (1:1, mass ratio) medium. During the whole cultivation process, the stirring speed of the reactor was 120 rpm, the temperature was 36.8° C., and the dissolved oxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inoculation density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com