Thin film patterning apparatus and method of fabricating color filter array substrate using the same

A technology of a color filter array and a manufacturing method, which is applied in the directions of optical filters, photolithographic process exposure devices, optics, etc., can solve the problems of a long time, waste of photoresist, increase of manufacturing process time and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Preferred embodiments of the present invention will be described in detail with reference to Examples illustrated in the accompanying drawings. Below, will refer to Figures 6 to 17E Preferred embodiments of the present invention are described in detail.

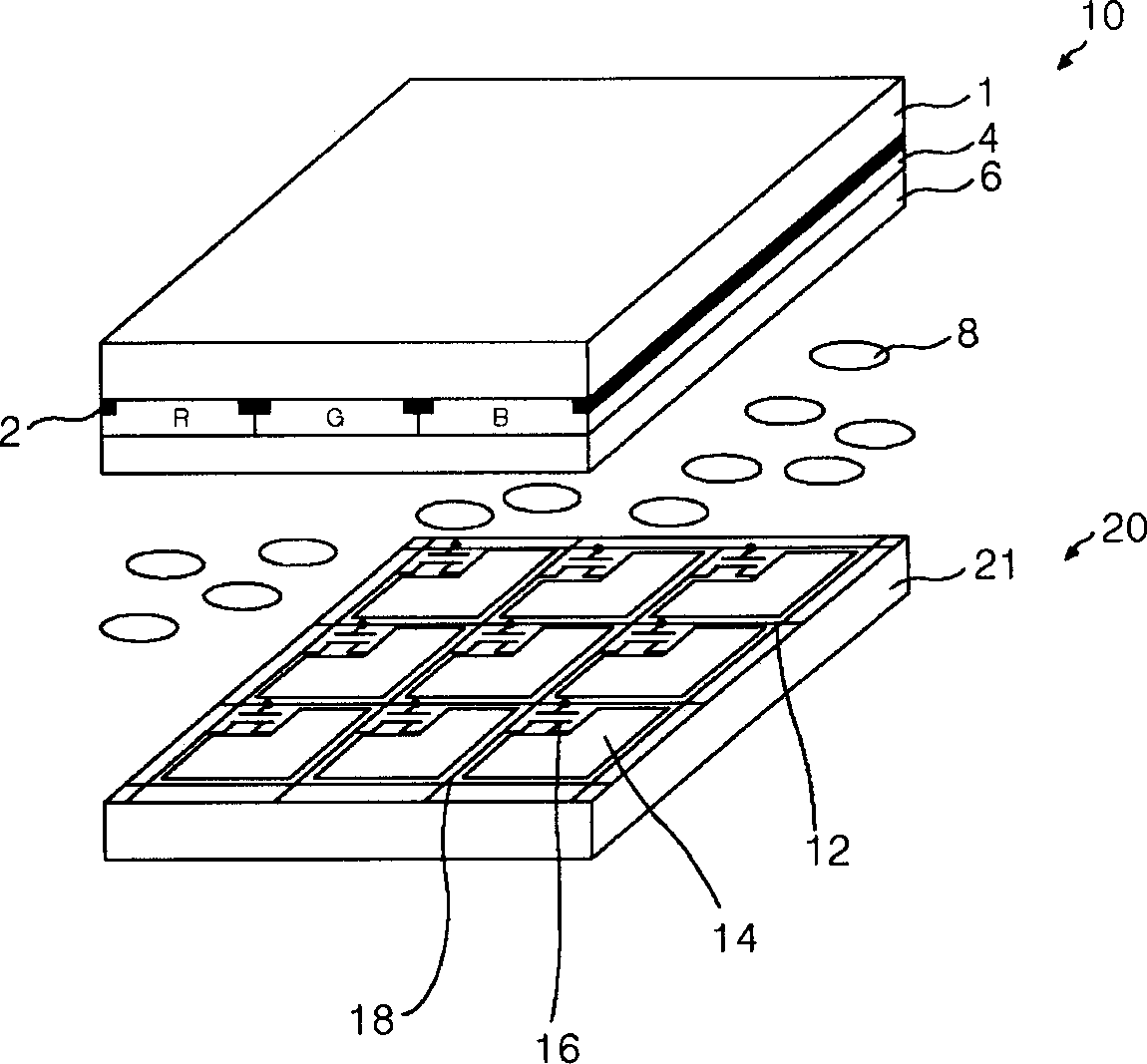

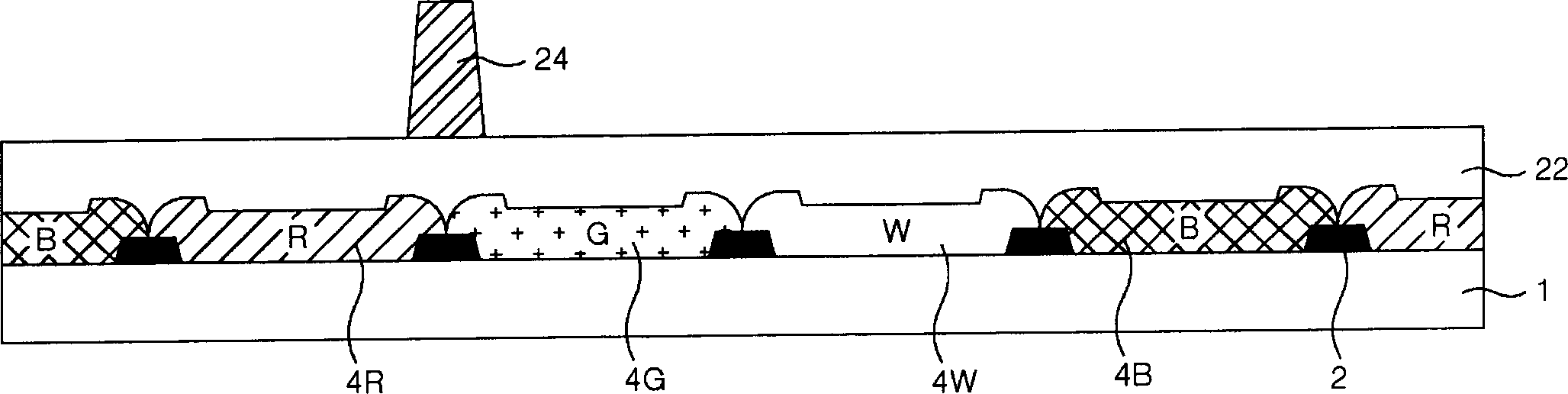

[0052] Figure 6 and 7 are respectively a plan view and a cross-sectional view showing the color filter array substrate according to the first embodiment of the present invention. refer to Figure 6 and 7 , the color filter array substrate according to the first embodiment of the present invention includes a black matrix 102 formed on an upper substrate 101; red, green and blue color filters 104R, 104G and 104B; a coating with a white color filter 104W layer 122; and liner 124 formed on coating layer 122.

[0053] The black matrix 102 is formed on the upper substrate 101 in a matrix form to define a plurality of unit regions forming the color filters 104 and to prevent light interference between adjacent units. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap