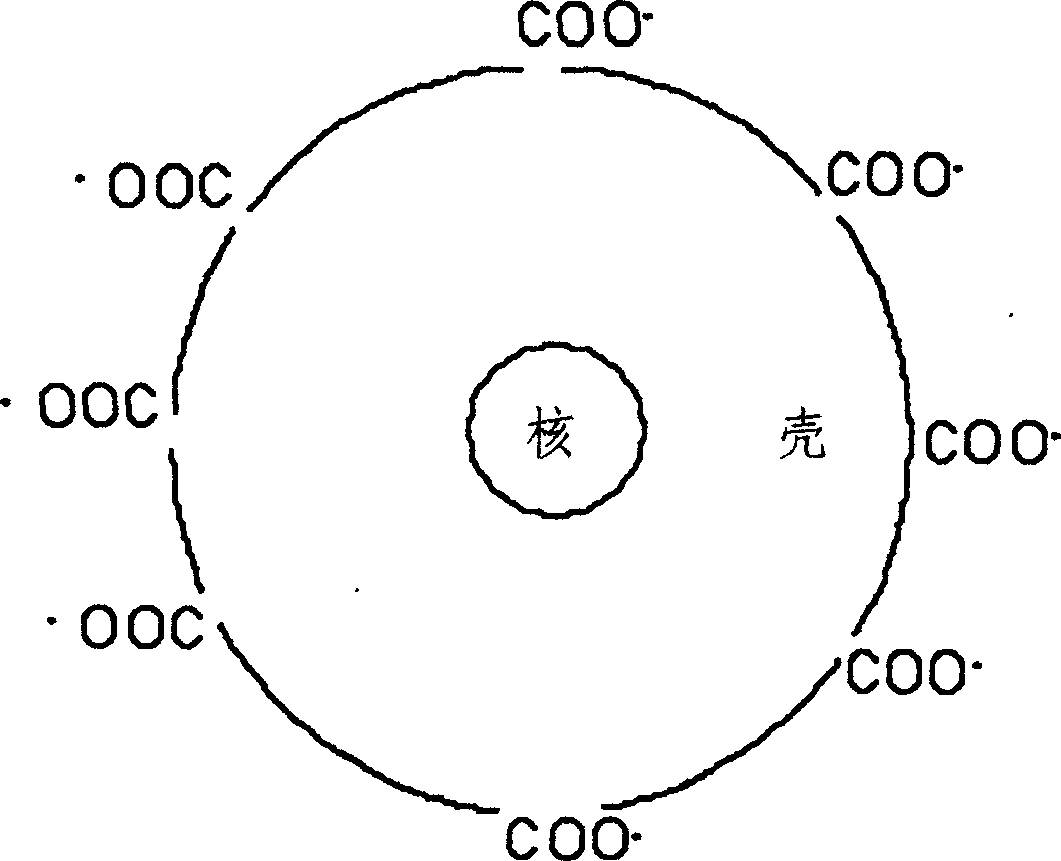

Water-base magnetic liquid and producing method thereof

A magnetic liquid, water-based technology, applied in magnetic liquids, radioactive carriers, gene therapy, etc., can solve the problems of large particle hydrodynamic diameter, complex connection process, low surface potential, etc., and achieve good biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

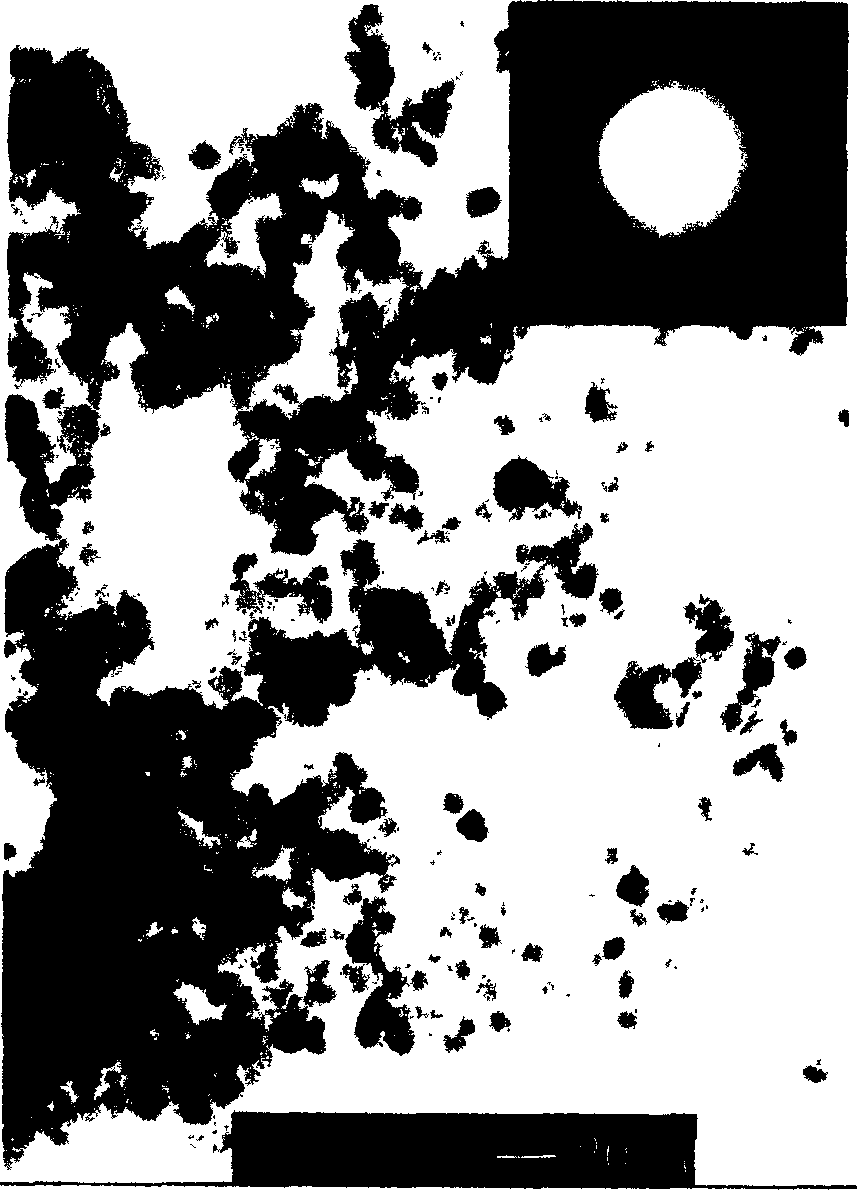

Embodiment 1

[0036] Take 9.6g FeCl 3 .6H 2 O, formulated as FeCl with a mass concentration of 60% 3solution, weighing 5g FeSO 4 .7H 2 O, formulated as FeSO with a mass concentration of 20% 4 solution, the two solutions are mixed to form an iron salt mixed solution, and the molar ratio of ferrous sulfate: ferric chloride=1:2. 20g of sodium alginate with a weight average molecular weight of 20,000 is dissolved in 100ml of concentrated ammonia of 25Wt% to form a mixed solution of sodium alginate and ammonia. The mass ratio to ferric oxide is 5:1. Mix the iron salt mixed solution and the sodium alginate ammonia mixed solution under stirring at 800 rpm, then react under stirring for 40 minutes, and the reaction temperature is stabilized at 90°C; Centrifuge the ferroferric oxide magnetic liquid to remove the precipitated large particles, ensure that the nano-ferric ferric oxide particles are uniform in size and dispersed in water stably, collect the supernatant as a stable water-based ferr...

Embodiment 2

[0038] Take 9.6g FeCl 3 .6H 2 O, formulated as FeCl with a mass concentration of 30% 3 solution, weighing 5g FeSO 4 .7H 2 O, formulated as FeSO with a mass concentration of 15% 4 solution, the rest of the steps are the same as in Example 1, and 50ml of magnetic liquid with an iron content of 3mg / ml can be obtained, and the saturation magnetization is about 0.5kA / m.

Embodiment 3

[0040] Take 9.6g FeCl 3 .6H 2 O, formulated as FeCl with a mass concentration of 45% 3 solution, weighing 5g FeSO 4 .7H 2 O, formulated as FeSO with a mass concentration of 30% 4 solution, the rest of the steps are the same as in Example 1, and 30ml of magnetic liquid with an iron content of 9mg / ml can be obtained, and the saturation magnetization is about 1.6kA / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| saturation magnetization | aaaaa | aaaaa |

| saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com