Visible light intercalation photocatalytic material and its preparing method

A technology of photocatalytic materials and intercalation materials, applied in the field of visible light intercalation photocatalytic materials and their preparation, to achieve the effects of high visible light activity, good structural stability, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

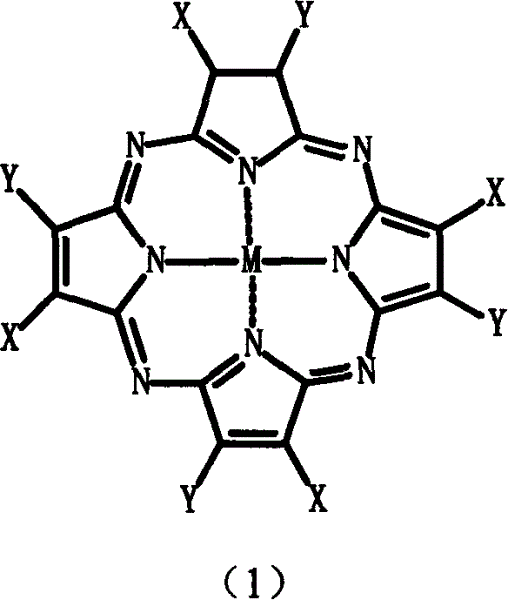

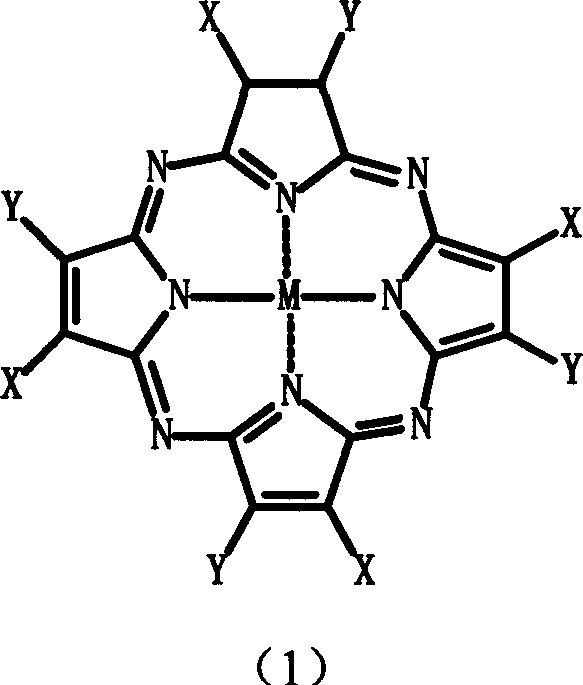

Method used

Image

Examples

Embodiment 1

[0020] 10 g K 2 Ti 4 o 9 Put in 2M HNO 3 Proton exchange in solution yields H2 Ti 4 o 9 . then H 2 Ti 4 o 9 Add it to a 20% n-butylamine solution by volume, stir at 5°C for 72 hours, and separate by filtration. will give the modified H of n-butylamine 2 Ti 4 o 9 Added to containing 1 g TiO 2 0.1M TiO 2 In the nano-sol, stir at 5°C for 96 hours, filter and separate, take 5 grams of the solid obtained by the above method and place it in an aqueous solution containing 0.025 grams of tetracarboxy copper phthalocyanine, stir at 0°C for 72 hours, filter and wash, After drying, the visible light intercalation photocatalytic material was obtained. The visible light photocatalytic activity of photocatalytic materials was tested, and the results are shown in Table 1.

Embodiment 2

[0022] 10 g K 2 Ti 4 o 9 Put in 2M HNO 3 Proton exchange in solution yields H 2 Ti 4 o 9 . H 2 Ti 4 o 9 Add it into a 20% n-hexylamine solution by volume, stir at 80° C. for 12 hours, and separate by filtration. The obtained n-hexylamine modified H 2 Ti 4 o 9 Added to the containing 0.02 g SiO 2 0.1M SiO 2 In the nano-sol, stir at 20° C. for 12 hours, filter and separate, add the obtained powder into water to fully hydrolyze, and filter and separate. Take 5 grams of the solid obtained by the above method and place it in an aqueous solution containing 0.0025 grams of tetrasulfonic acid copper phthalocyanine, stir at 80° C. for 12 hours, filter and wash, and dry to obtain a visible light intercalation photocatalytic material. The visible light photocatalytic activity of photocatalytic materials was tested, and the results are shown in Table 1.

Embodiment 3

[0024] 10 g K 4 Nb 6 o 17 Put in 2M HNO 3 Proton exchange in solution yields H 4 Nb 6 o 17 . will get H 4 Nb 6 o 17 Add it into a 10% n-octylamine solution by volume percentage, stir at 60° C. for 18 hours, and separate by filtration. The obtained n-octylamine modified H 4 Nb 6 o 17 Added to containing 0.2 g ZrO 2 ZrO 2 In the nano-sol, stirred at 80°C for 12 hours, and separated by filtration. Take 5 grams of the solid obtained by the above method and place it in a methanol solution containing 0.05 grams of octacarboxyiron phthalocyanine, stir at 80° C. for 12 hours, filter and wash, and dry to obtain a visible light intercalation photocatalytic material. The visible light photocatalytic activity of photocatalytic materials was tested, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com