Rapid preparation of intercalation vermiculite superfine powder by ball grinding method

An ultra-fine powder, ball milling technology, applied in grain processing and other directions, can solve the problems of slow intercalation (several days to several months, high cost, complex process, etc., to improve intercalation and pulverization efficiency, improve Intercalation reaction efficiency, effect of efficient intercalation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The vermiculite of Shijiazhuang Dongping Mining and Building Materials Factory was crushed through a jet mill, and passed through a 100-mesh sieve to obtain the raw material vermiculite VMT. Its chemical composition is: SiO 2 : 41.2%, AL 2 o 3 : 12.68%, MgO: 24.22%, CaO: 0.96%, FeO: 1.54%, Fe 2 o 3 : 4.06%, TiO 2 : 1.33%, K 2 O: 5.97%, P 2 o 5 : 0.06%, H 2 O: 3%, Na 2 O: 1.6%, MnO: 0.043%, TiO: 5.097%, loss on ignition 6.71%.

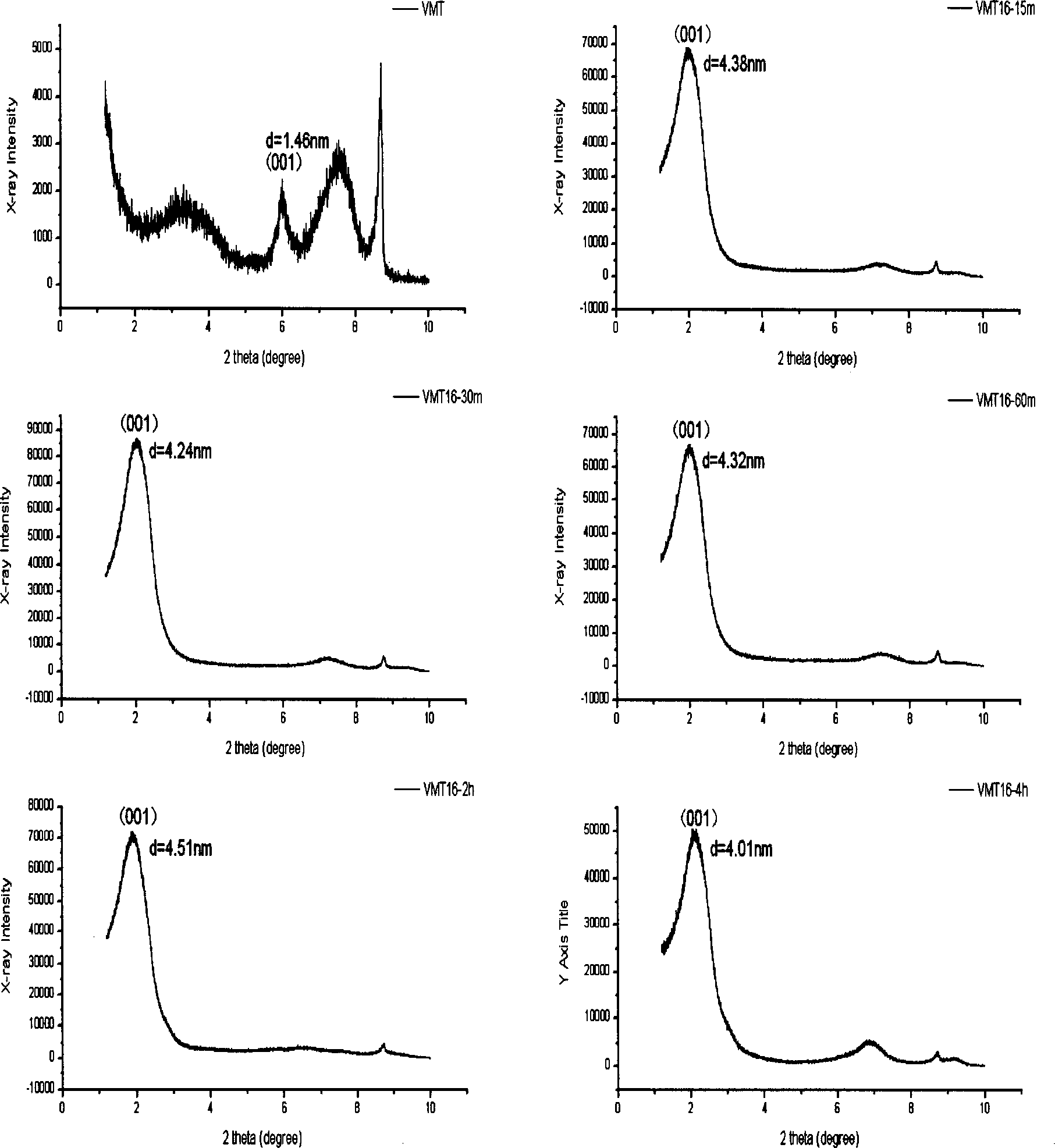

[0020] First, 50 grams of VMT sample was mixed with 2 times CEC of cetyltrimethylammonium bromide and 300 ml of deionized water to form a slurry. Grind in a ball mill for 15 minutes, 30 minutes, 1 hour, 2 hours, and 4 hours respectively. After grinding, the samples taken out are centrifuged, filtered, and washed 5 to 7 times with deionized water. + No white precipitate (AgBr) was detected. Finally, the centrifuged and filtered samples were dried and ground into powder to obtain samples VMT16-15m, VMT16-30m, VMT16-60m, VMT16-2h and VMT16...

Embodiment 2

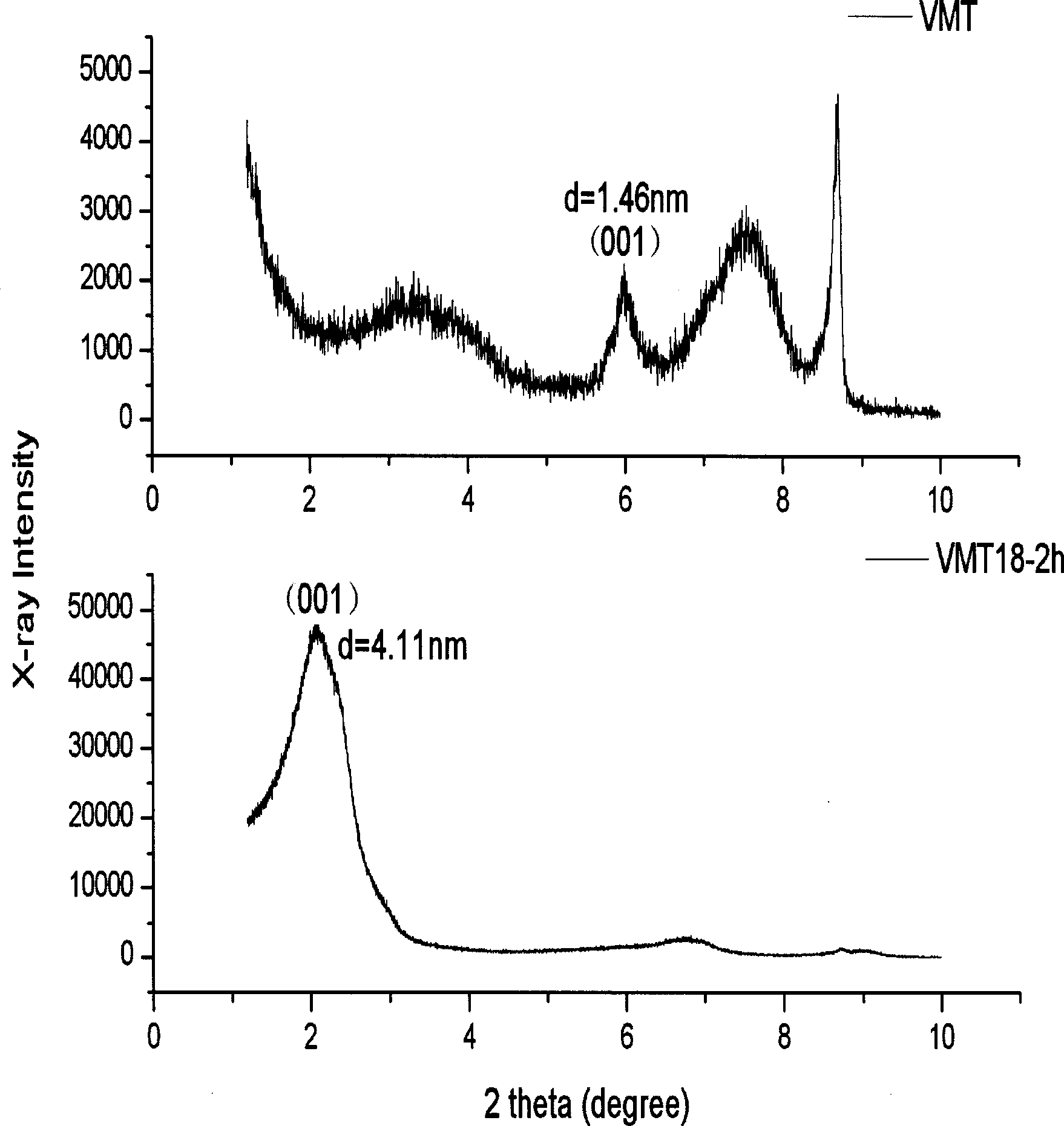

[0024] First, mix and stir 50 grams of VMT sample with 2 times CEC of octadecyltrimethylammonium bromide and 300 ml of deionized water to form a slurry. Grind in a ball mill for 2 hours. After grinding, the sample taken out is centrifuged, filtered, and washed 5 to 7 times with deionized water. + No white precipitate (AgBr) was detected, and finally the centrifuged and filtered sample was dried and ground into powder to obtain the sample VMT18-2h respectively. X-ray powder diffraction (XRD) test was performed on VMT and VMT18-2h respectively. The corresponding spectra are shown in Fig. 4 respectively.

[0025] Fig. 4 is the XRD comparison pattern of samples VMT and VMT18-2h. The d value of the (001) plane diffraction peak of VMT in the figure, that is, the (001) crystal plane spacing is 1.46nm. The diffraction peak with a d value of 1.46nm of VMT18-2h disappeared, and the diffraction peak of nm appeared at the same time. It shows that after the ball milling method, the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com