Method for producing extracellular mucopoly-saccharide using rhamnose lactobacillus and product

A technology of Lactobacillus rhamnosus and mucopolysaccharides, applied in the field of functional food and pharmaceutical products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] The specific embodiment: the specific implementation method steps of the present invention are as follows:

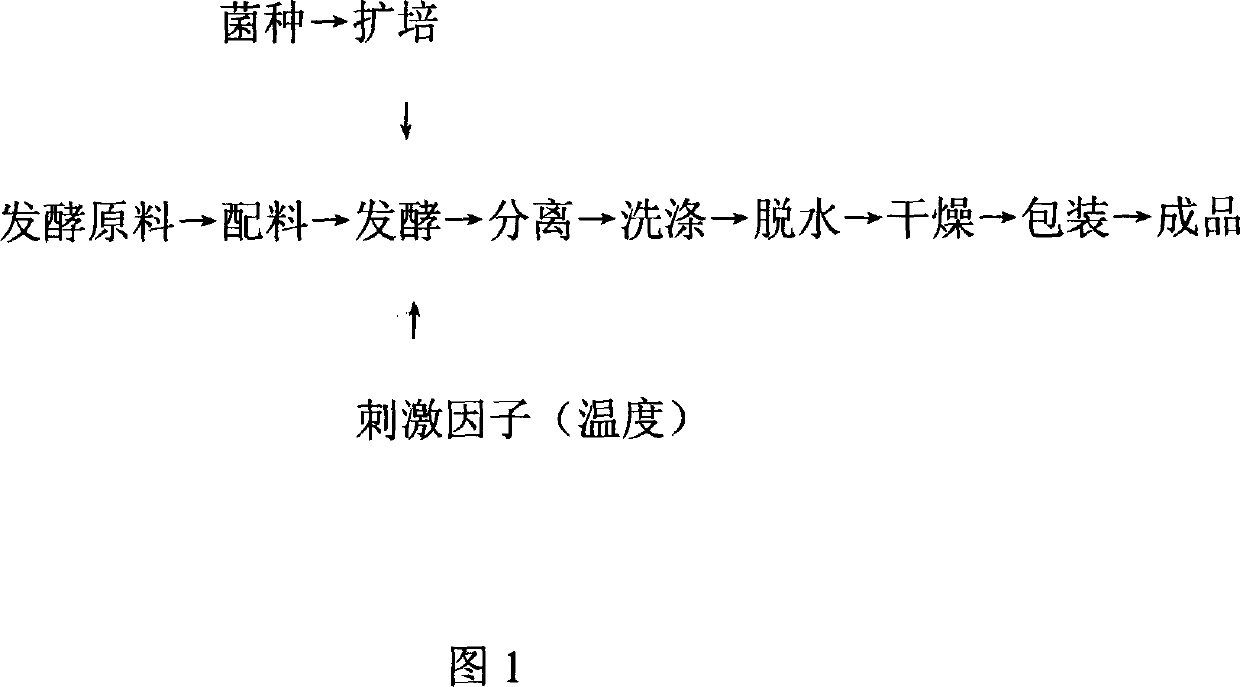

[0018] (1) Technological process: See attached drawing 1.

[0019] (2) Operation points:

[0020] ① Strains: Lactobacillus rhamnosus (L.R-008) is cultured on a slant, in a triangular flask, and expanded in a seed tank, and then connected to a fermenter for fermentation.

[0021] ② Fermentation raw materials: whey powder, glucose, diamine hydrogen citrate, MgSO 4 ·7H 2 O, MnSO 4 ·H 2 O. Tween-80.

[0022] ③ Ingredients: Fermentation raw materials are put into the fermentation tank according to a certain ratio of ingredients. The specific proportions are: whey powder 5% to 10%, glucose 1% to 5%, diamine hydrogen citrate 0.1% to 1%, MgSO 4 ·7H 2 O0.02%~0.1%, MnSO 4 ·H 2 O0.01%~0.1%, Tween-80 1ml / L~2ml / L, the balance is water;

[0023] ④ Fermentation: use glucose and lactose as carbon sources, maintain pH 5.5-6.0, and ferment at 32°C to 37°C for 24 hours t...

Embodiment 1

[0037] Key points of operation: See Figure 1 for the process flow

[0038] ① Expanded culture of strains: Lactobacillus rhamnosus L.R-008 was cultured on a slant, cultured in a triangular flask, continued to expand the culture in the seed tank, and then connected to a fermenter for fermentation.

[0039] ② Fermentation raw materials: whey powder, glucose, diamine hydrogen citrate, MgSO 4 ·7H 2 O, MnSO 4 ·H 2 O. Tween-80.

[0040] ③ Ingredients: Fermentation raw materials are put into the fermentation tank according to a certain ratio of ingredients. The specific ratio is: whey powder 5%, glucose 1.5%, diamine hydrogen citrate 0.2%, MgSO 4 ·7H 2O0.04%, MnSO 4 ·H 2 O0.04%, Tween-80 1ml / L, the balance is water;

[0041] ④Fermentation: After the above-mentioned raw materials are prepared, the inoculation amount is 3% (v / v), and the pH is maintained at 5.5-6.0, and fermented at 34°C to 37°C for 50 hours. The fermenter was stirred intermittently at 100r / min without supple...

Embodiment 2

[0050] Key points of operation: See Figure 1 for the process flow

[0051] ① Expanded culture of strains: Lactobacillus rhamnosus L.R-008 was cultured on a slant, cultured in a triangular flask, continued to expand the culture in the seed tank, and then connected to a fermenter for fermentation.

[0052] ② Fermentation raw materials: whey powder, glucose, diamine hydrogen citrate, MgSO 4 ·7H 2 O, MnSO 4 ·H 2 O. Tween-80.

[0053] ③ Ingredients: Fermentation raw materials are put into the fermentation tank according to a certain ratio of ingredients. The specific ratio is: whey powder 8%, glucose 0.5%, diamine hydrogen citrate 0.5%, MgSO 4 ·7H 2 O0.06%, MnSO 4 ·H 2 O0.02%, Tween-80 1.5ml / L, the balance is water;

[0054] ④Fermentation: After the above-mentioned raw materials are prepared, the inoculation amount is 3% (v / v), and the pH is maintained at 5.5-6.0, and the fermentation is carried out at 32°C to 35°C for 68 hours. The fermenter was stirred intermittently a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com