Technology of eliminating Nb microalloyed steel mixed crystal fexture in thin plate blank continuous casting continuous milling process

A technology of thin slab continuous casting and microalloyed steel, which is applied in metal rolling and other directions, can solve the problems of uneven structure of microalloyed steel, and achieve the effect of improving comprehensive performance, formability and fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Technological process: electric furnace or converter smelting, refining, thin slab continuous casting, slabs solidified and then directly enter the roller hearth heating or soaking furnace, high pressure water descaling, hot rolling, laminar cooling, coiling.

[0040] Chemical composition of molten steel: 0.05-0.07%C-0.2-0.3%Si-1.0-1.2%Mn-0.01-0.02%P-0.003-0.005%S-0.06%Nb.

[0041] Process parameters: slab entering furnace temperature: 980~1050℃; soaking furnace exit temperature: 1160~1200℃; starting rolling temperature: 1080~1120℃; final rolling temperature: 840~860℃; coiling temperature: 600℃.

[0042] The organization of the steel belt see figure 1, the mechanical properties of the steel strip are shown in Table 1

[0043] Strip thickness

Embodiment 2

[0045] Technological process: electric furnace or converter smelting, refining, thin slab continuous casting, slabs solidified and then directly enter the roller hearth heating or soaking furnace, high pressure water descaling, hot rolling, laminar cooling, coiling.

[0046] Chemical composition of molten steel: 0.03-0.05%C-0.2-0.3%Si-1.5-1.8%Mn-0.01%P-0.003%S-0.05%Nb-0.2%Mo.

[0047] Process parameters: Billet entering furnace temperature: 950-1000°C; exiting soaking furnace temperature: 1160-1200°C; starting rolling temperature: 1080-1120°C; final rolling temperature: 830-850°C; coiling temperature: 500-550 ℃.

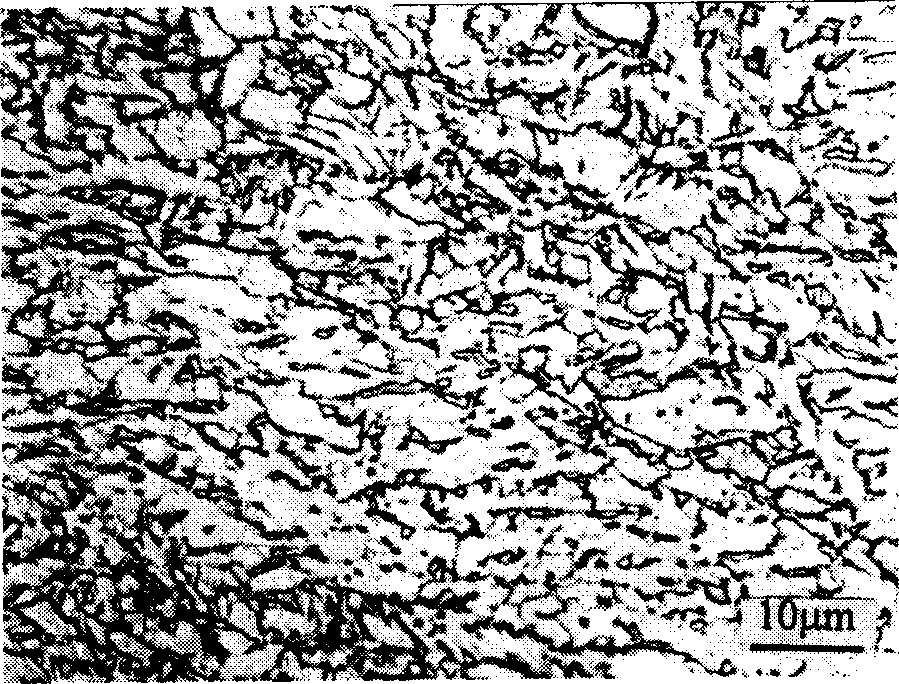

[0048] The organization of the steel belt see figure 2 , the mechanical properties of the steel strip are shown in Table 2

[0049] Strip thickness

Embodiment 3

[0051] Technological process: electric furnace or converter smelting, refining, thin slab continuous casting, slab solidified and then directly enters the roller hearth heating or soaking furnace, high pressure water descaling, hot rolling, laminar cooling, coiling

[0052] Chemical composition of molten steel: 0.05-0.07%C-0.3-0.5%Si-0.3-0.6%Mn-0.09-0.12%P-0.003-0.005%S-0.05%Nb-0.20-0.30%Cu-0.2-0.3%Ni.

[0053] Process parameters: slab entering furnace temperature: 950-1000°C; exiting soaking furnace temperature: 1140-1170°C; starting rolling temperature: 1040-1070°C; final rolling temperature: 840-860°C; coiling temperature: 600°C.

[0054] The organization of the steel belt see image 3 , the mechanical properties of the steel strip are shown in Table 3.

[0055] Strip thickness

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com