Panel display having integrated vertical groove type cathode structure and its manufacturing technology

A flat-panel display and cathode structure technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems restricting the application of carbon nanotubes, achieve good field emission characteristics, prevent ignition, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

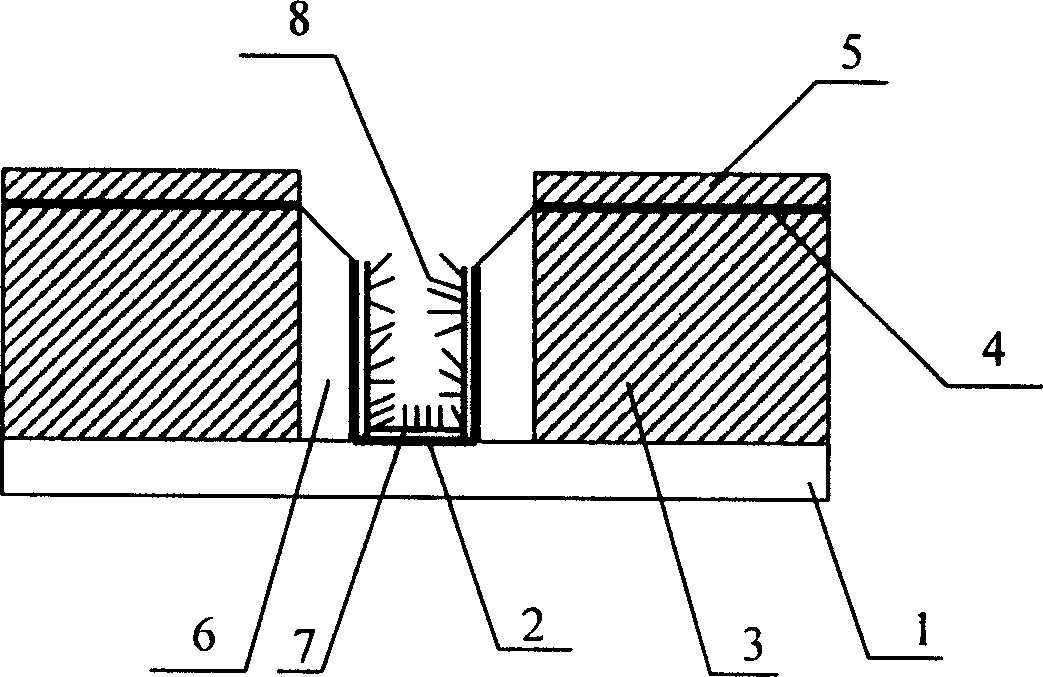

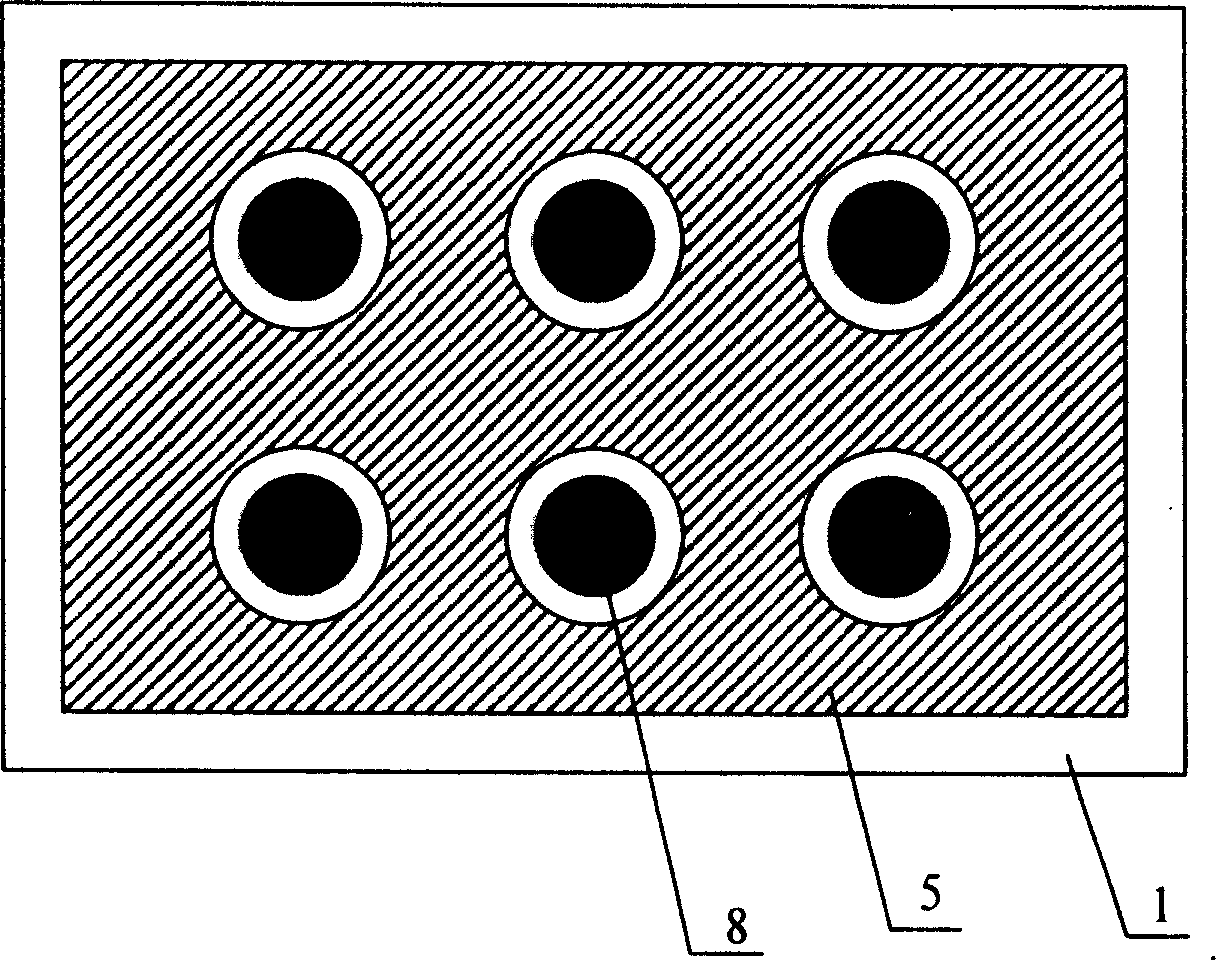

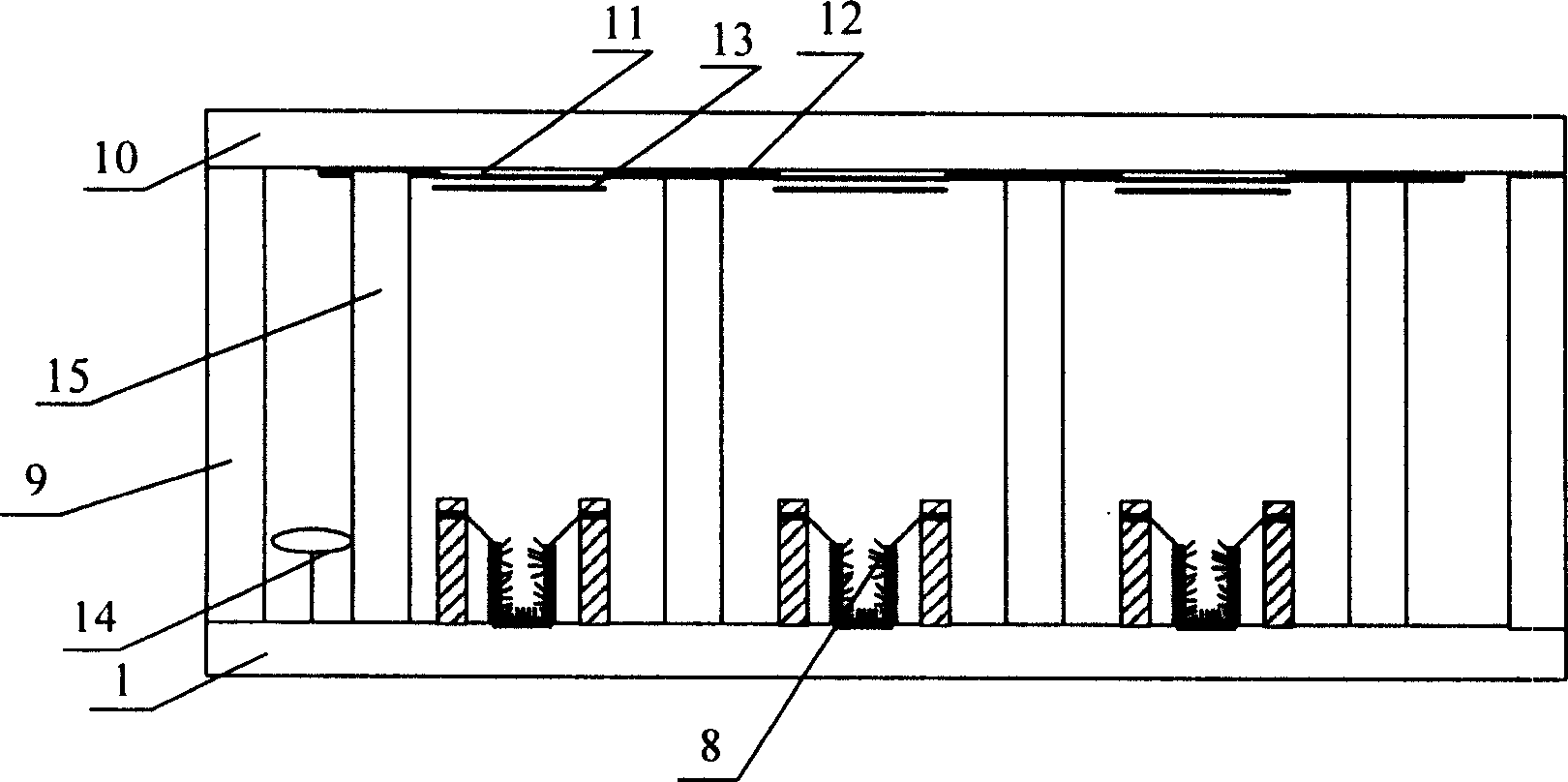

[0038] A flat-panel display with an integrated vertical groove-like cathode structure includes a sealed vacuum chamber composed of a cathode panel 1, an anode panel 10 and a surrounding glass frame 9; a control grid 4 for controlling electron emission and a carbon nanometer for growth Tube cathode 8; photolithographic anode conductive layer 11 on anode panel 10 and phosphor layer 13 prepared on anode conductive layer 11; supporting wall structure 15 and getter attachment 14. An integrated vertical groove-shaped cathode structure is fabricated on the cathode panel 1, which greatly increases the emission area of the carbon nanotube cathode, fully utilizes the good field emission characteristics of the carbon nanotubes prepared by the direct growth method, and simultaneously The control gate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com