Panel display having adulterated polycrystal silicon field emission cathode array structure and its manufacturing technology

A flat-panel display and array structure technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of increasing the overall cost of the device, improve the success rate of manufacturing, simplify the manufacturing process, and improve integration degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

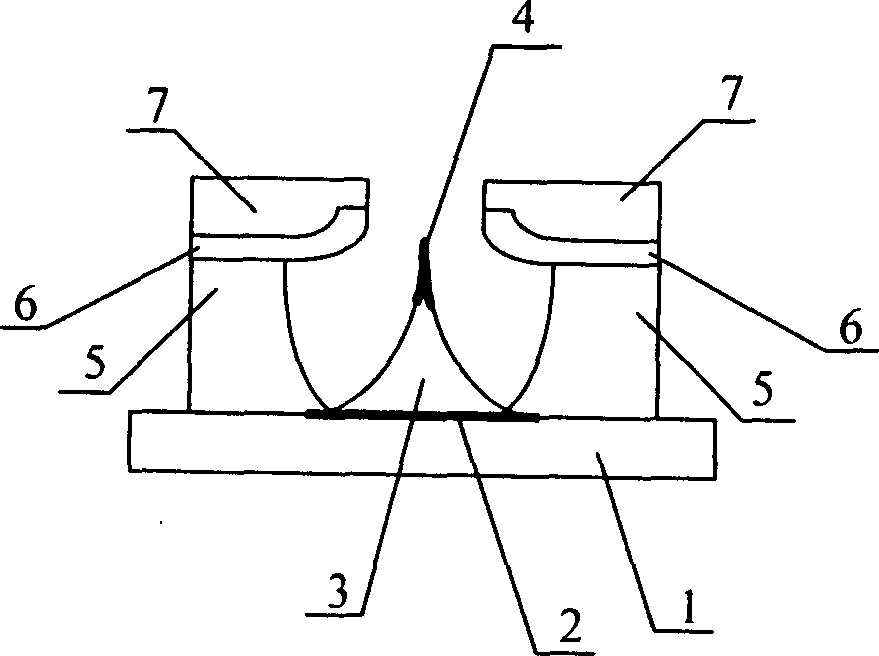

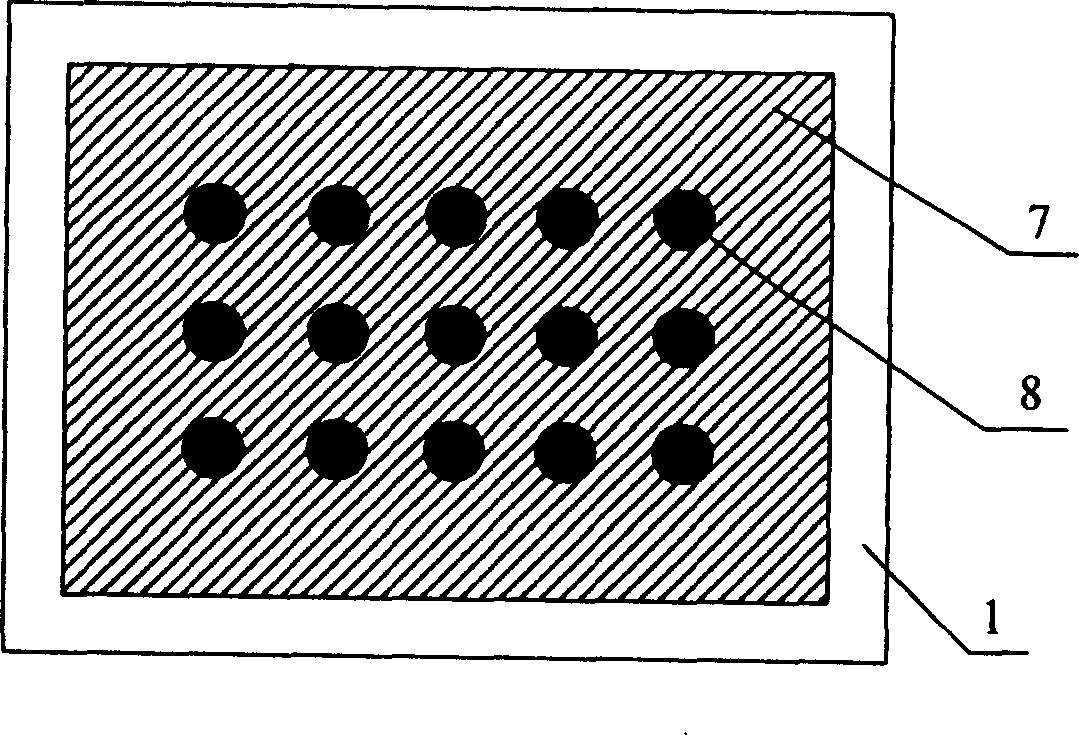

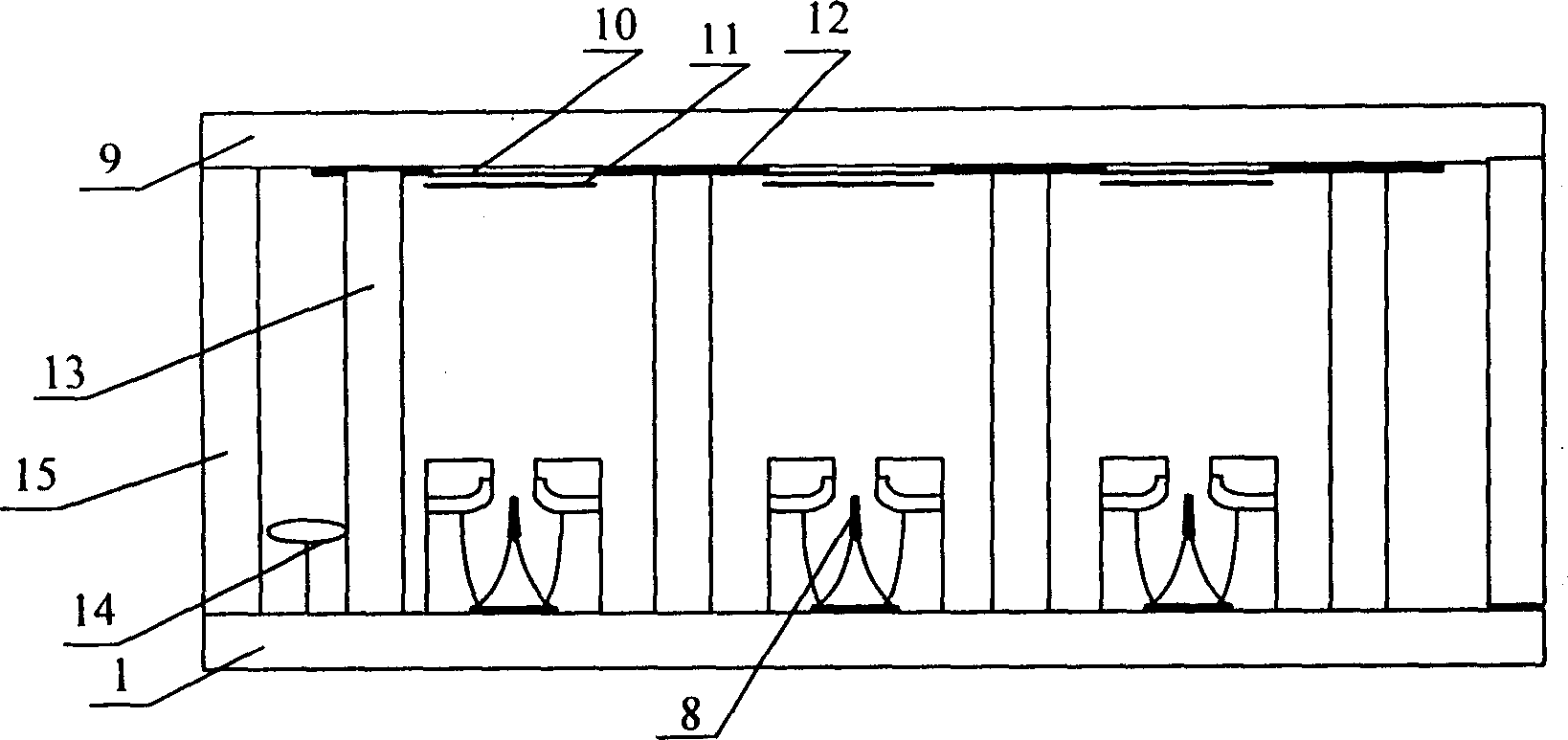

[0048] Such as image 3 Shown, the present invention comprises the sealed vacuum chamber that is made of cathode panel 1 (i.e. substrate material glass 1), anode panel 9 and surrounding glass enclosing frame 15; On anode panel 9, the anode conductive strip 10 of photoetching out and making Phosphor powder layer 11 on the anode conductive strip 10; insulating paste layer 12 printed on the non-display area of the anode conductive strip 10; supporting wall 13 and getter accessory element 14 arranged between the cathode panel 1 and the anode panel 9 , a doped polysilicon field emission cathode array structure is fabricated on the cathode panel 1 . On the cathode panel, there are doped polysilicon field emission cathode array structure and carbon nanotube cathode; the control gate used to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com