Method of in-situ depositing high dielectric constant Al2O3 and metal film on GaN base compound material

A high dielectric constant, metal film technology, applied in the field of microelectronics, can solve the problems of thickness uniformity, poor inter-chip thickness repeatability, inability to achieve precise control, low work efficiency, etc., to achieve precise control of film thickness, cost savings, Improve ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

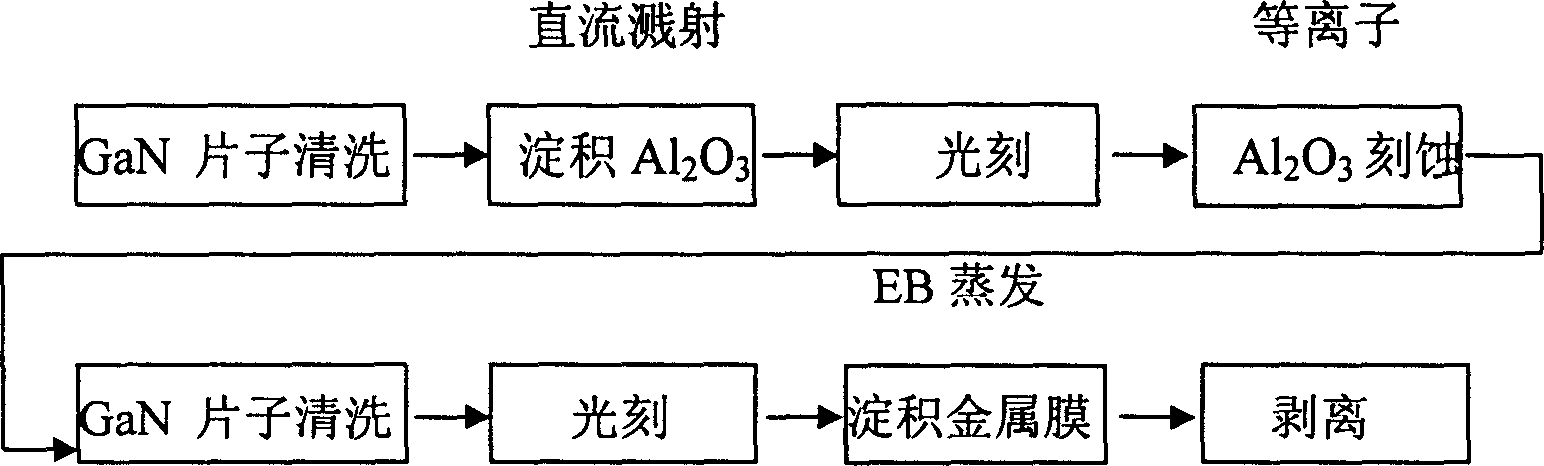

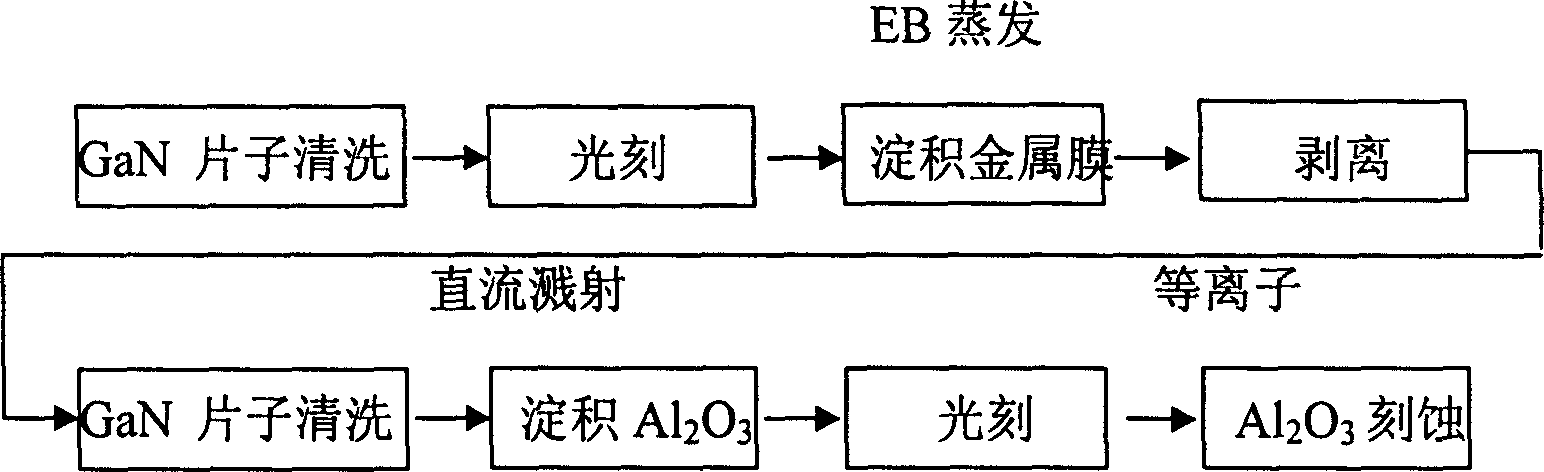

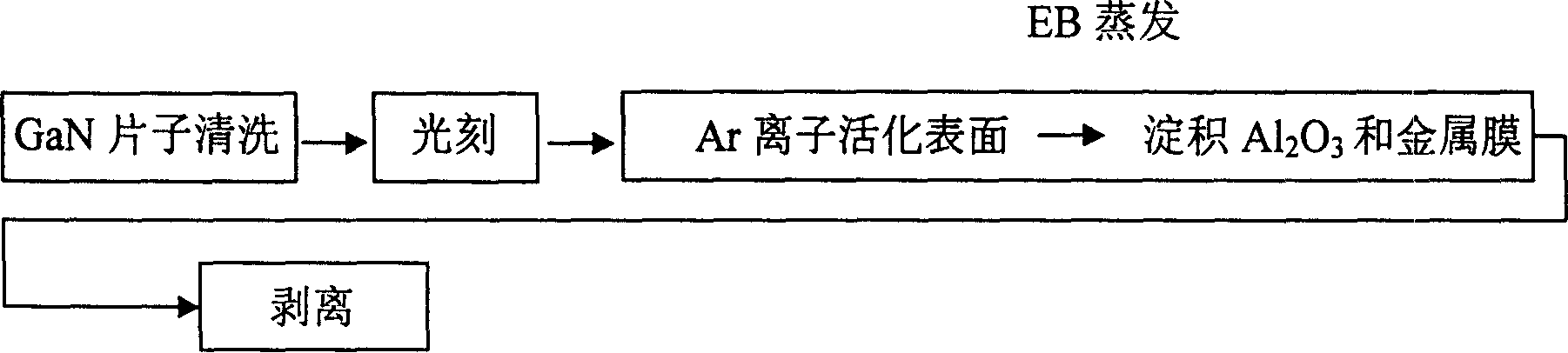

Method used

Image

Examples

Embodiment 1

[0097] On the GaN wafer, evaporate Al first 2 o 3 After evaporating the metal, the metal uses Ni (nickel) and Au (gold), that is, Al first 2 o 3 , after Ni / Au, the specific process is:

[0098] The first step: clean the substrate of GaN-based material, and then use N 2 blow dry;

[0099] The second step: photolithography pattern on the cleaned GaN substrate;

[0100] Step 3: Put the photolithographic film into the reaction chamber of the electron beam evaporation table, and vacuumize it to a predetermined value of 1.8×10 -3 Above Pa, activate the GaN substrate surface with argon ions for 30 seconds, and perform Al 2 o 3 Evaporation deposition of films and Ni / Au metal films:

[0101] (1) Carry out Al according to the following process conditions 2 o 3 Evaporation of the film:

[0102] a. Turn on the electronic power supply of the evaporation table, after preheating, turn on the high voltage and set it to 10kv;

[0103] b. Turn ON the switch of the film thickness met...

Embodiment 2

[0125] On GaN-based materials, first evaporate Al 2 o 3 After evaporating the metal, the metal adopts Pt (platinum) and Au (gold), that is, Al first 2 o 3 After Pt / Au, the specific process is as follows:

[0126] The first step: clean the substrate of GaN-based material, and then use N 2 blow dry;

[0127] The second step: photolithography pattern on the cleaned GaN substrate;

[0128] Step 3: Put the photolithographic film into the reaction chamber of the electron beam evaporation table, and vacuumize it to a predetermined value of 1.8×10 -3 Above Pa, activate the GaN substrate surface with argon ions for 30 seconds, and perform Al 2 o 3 Evaporation deposition of films and Pt / Au metal films:

[0129] (1) carry out Al 2 o 3 Conditions for film evaporation:

[0130] a. The electron beam high voltage is still set at 10kv;

[0131] b. Set Al on the film thickness meter 2 o 3 Density D and Z coefficients, namely D: 4.0g / cm 3 Z: 1.00;

[0132] c. Use the controlle...

Embodiment 3

[0149] On the GaN substrate, the metals Ti (titanium), Al (aluminum), Ti (titanium), Au (gold) are evaporated in sequence, and then Al is evaporated. 2 o 3 , that is, the Ti / Al / Ti / Au metal film is evaporated first, and then the Al 2 o 3 In-situ evaporation, the specific process is:

[0150]The first step: clean the substrate of GaN-based material, and then use N 2 blow dry;

[0151] The second step: photolithography pattern on the cleaned GaN substrate;

[0152] Step 3: Put the photolithographic film into the reaction chamber of the electron beam evaporation table, and vacuumize it to a predetermined value of 1.8×10 -3 Above Pa, activate the GaN substrate surface with argon ions for 30 seconds, and perform Ti / Al / Ti / Au metal film and Al 2 o 3 Evaporative deposition of films:

[0153] 1. The conditions for evaporating Ti / Al / Ti / Au metal film in sequence:

[0154] (1) Evaporated Ti film

[0155] a. The vacuum degree of the reaction chamber is maintained at 1.8×10 -3 Abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com