Method of in-situ depositing high dielectric constant Al2O3 and metal film on GaN base compound material

A high dielectric constant, metal film technology, applied in the field of microelectronics, can solve the problems of uniform thickness, poor repeatability of thickness between sheets, uneven composition thickness, and lack of precise control, etc., to achieve precise control of film thickness and quality Good, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

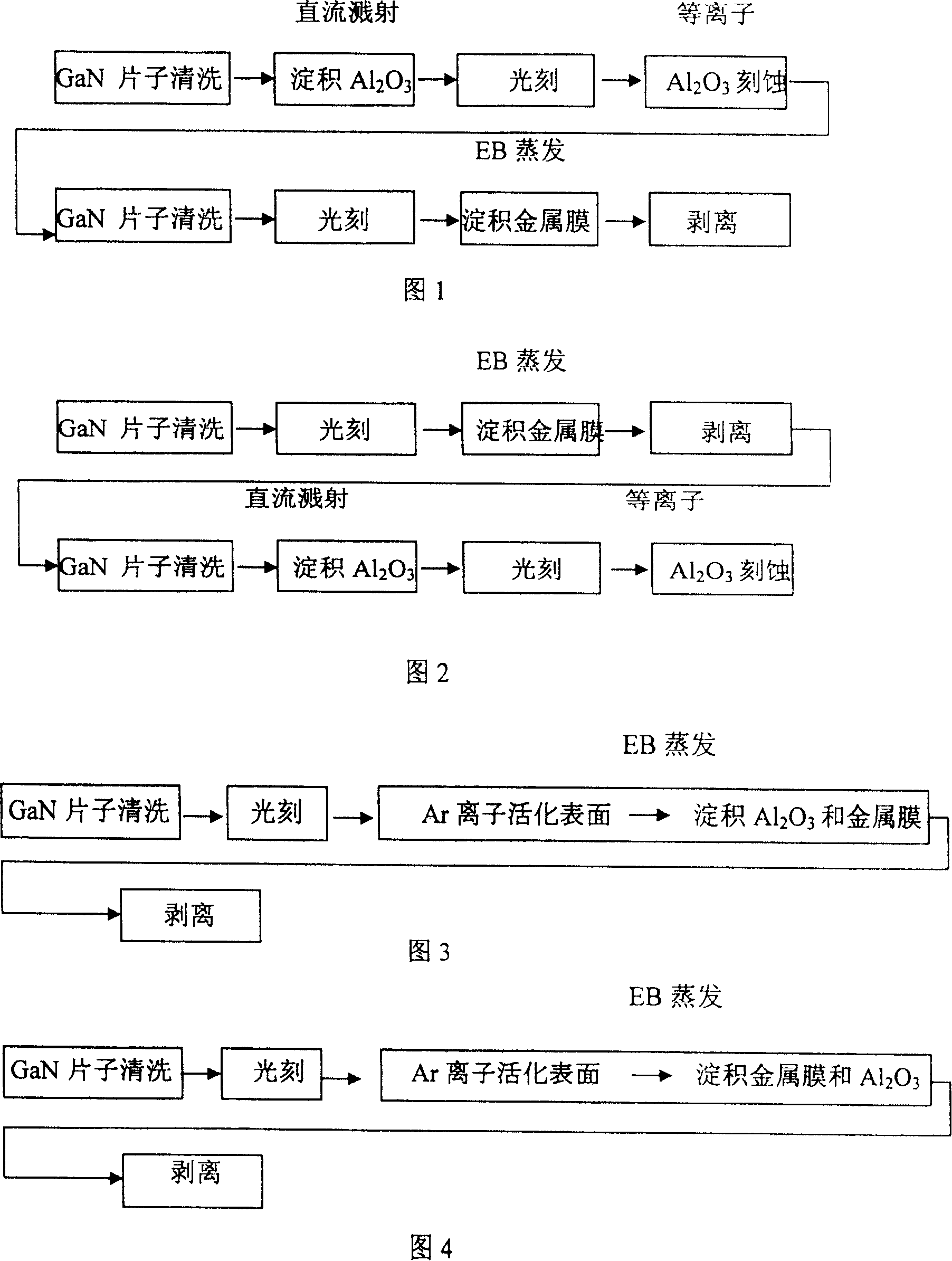

Method used

Image

Examples

Embodiment l

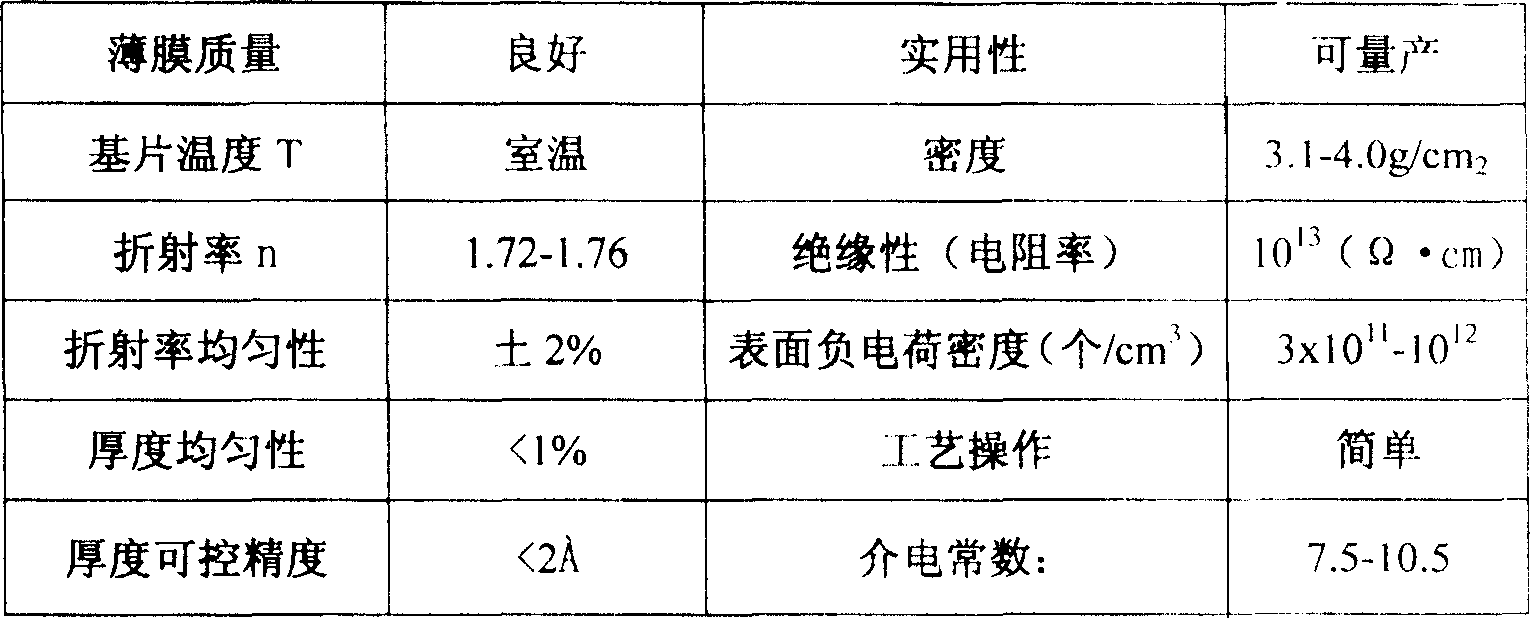

[0097] On the GaN wafer, evaporate Al first 2 o 3 After evaporating the metal, the metal uses Ni (nickel) and Au (gold), that is, Al first 2 o 3 , after Ni / Au, the specific process is:

[0098] The first step: cleaning the substrate of GaN-based material, and then drying it with N2;

[0099] The second step: photolithography pattern on the cleaned GaN substrate;

[0100] Step 3: Put the photolithographic film into the reaction chamber of the electron beam evaporation table, and vacuumize it to a predetermined value of 1.8×10 -3 Above Pa, activate the GaN substrate surface with argon ions for 30 seconds, and perform Al 2 o 3 Evaporation deposition of films and Ni / Au metal films:

[0101] (1) Carry out Al according to the following process conditions 2 o 3 Evaporation of the film:

[0102] a. Turn on the electronic power supply of the evaporation table, after preheating, turn on the high voltage and set it to 10kv;

[0103] b. Turn ON the switch of the film thickness ...

Embodiment 2

[0126] On GaN-based materials, first evaporate Al 2 o 3 After evaporating the metal, the metal adopts Pt (platinum) and Au (gold), that is, Al first 2 o 3 After Pt / Au, the specific process is as follows:

[0127] The first step: clean the substrate of GaN-based material, and then use N 2 blow dry;

[0128] The second step: photolithography pattern on the cleaned GaN substrate;

[0129] Step 3: Put the photolithographic film into the reaction chamber of the electron beam evaporation table, and vacuumize it to a predetermined value of 1.8×10 -3 Above Pa, activate the GaN substrate surface with argon ions for 30 seconds, and perform Al 2 o 3 Evaporation deposition of films and Pt / Au metal films:

[0130] (1) carry out Al 2 o 3 Conditions for film evaporation:

[0131] a. The electron beam high voltage is still set at 10kv;

[0132] b. Set Al on the film thickness meter 2 o 3 Density D and Z coefficients, namely D: 4.0g / cm 3 Z: 1.00;

[0133] c. Use the controlle...

Embodiment 3

[0150] On the GaN substrate, the metals Ti (titanium), Al (aluminum), Ti (titanium), Au (gold) are evaporated in sequence, and then Al is evaporated. 2 o 3 , that is, the Ti / Al / Ti / Au metal film is evaporated first, and then the Al 2 o 3 In-situ evaporation, the specific process is:

[0151]The first step: clean the substrate of GaN-based material, and then use N 2 blow dry;

[0152] The second step: photolithography pattern on the cleaned GaN substrate;

[0153] Step 3: Put the photolithographic film into the reaction chamber of the electron beam evaporation table, and vacuumize it to a predetermined value of 1.8×10 -3 Above Pa, activate the GaN substrate surface with argon ions for 30 seconds, and perform Ti / Al / Ti / Au metal film and Al 2 o 3 Evaporative deposition of films:

[0154] 1. The conditions for evaporating Ti / Al / Ti / Au metal film in sequence:

[0155] (1) Evaporated Ti film

[0156] a. The vacuum degree of the reaction chamber is maintained at 1.8×10 -3 Abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com