Semiconductor structure and manufacturing method theereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of inconvenience and general products, and achieve the effect of improving pattern uniformity and reducing pattern load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

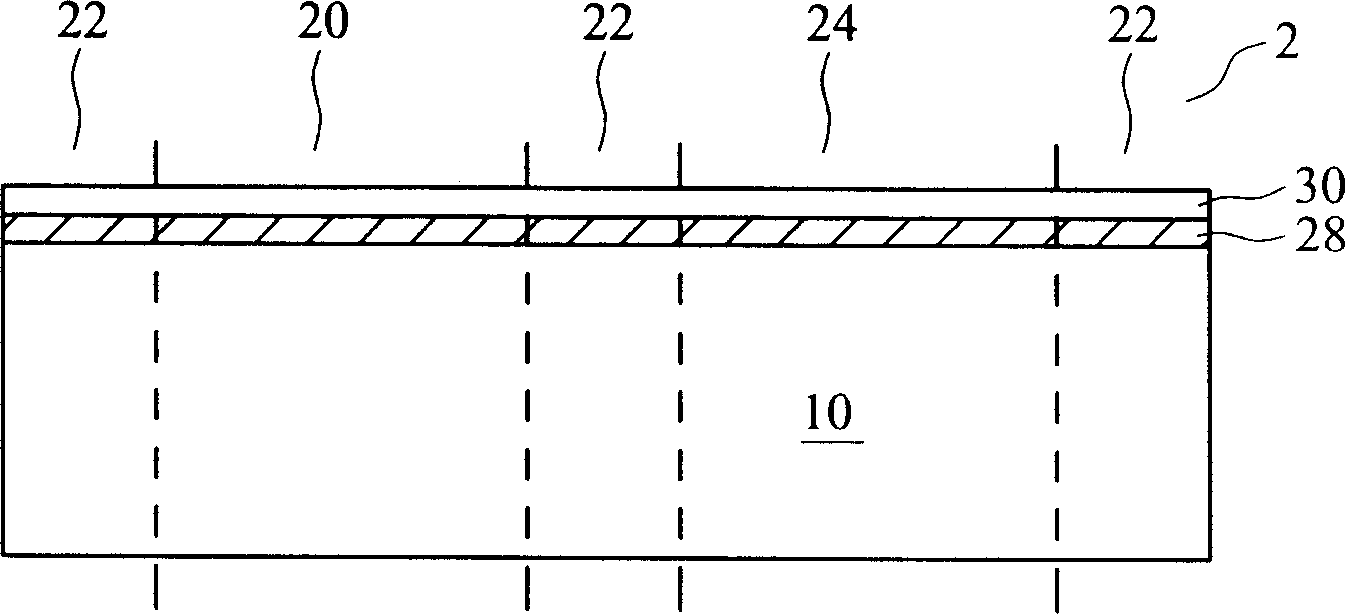

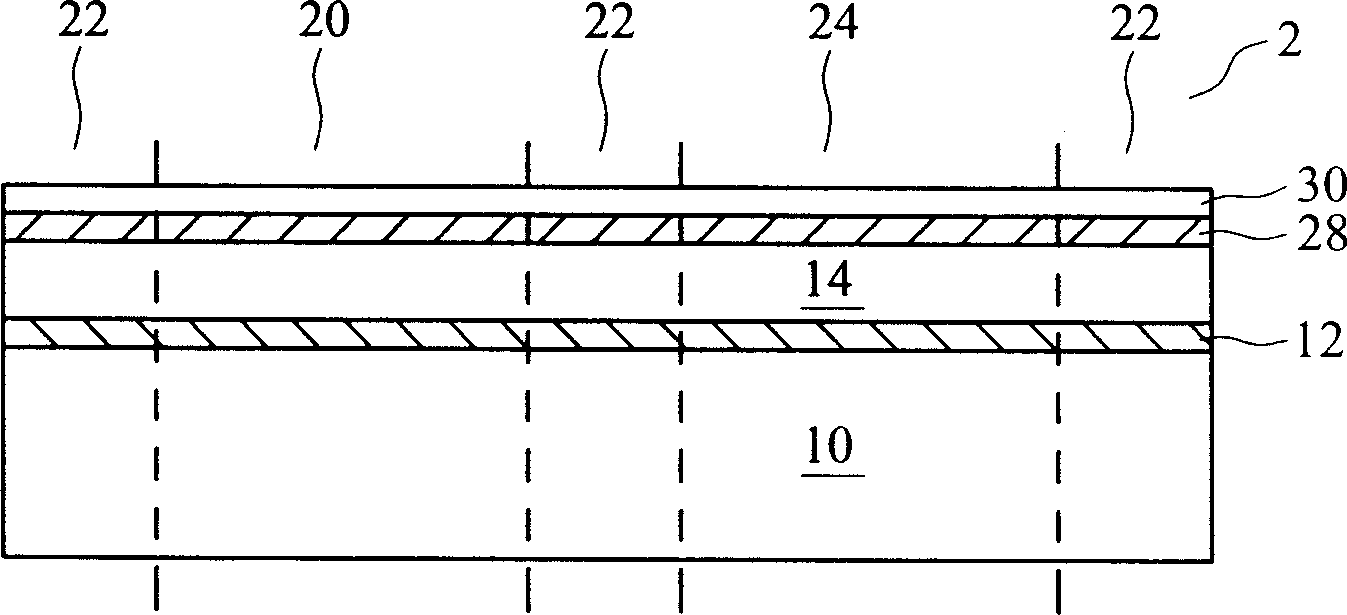

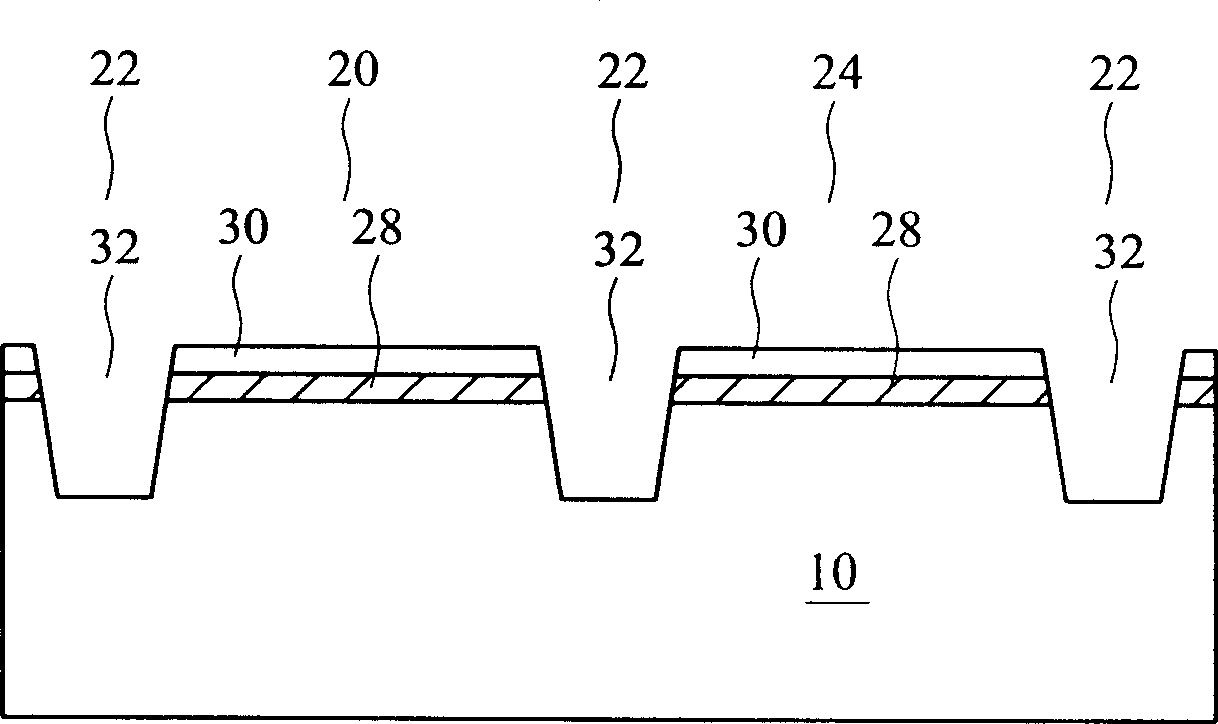

[0043] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, the specific implementation, structure and manufacturing method of the semiconductor structure and its manufacturing method proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , steps, features and effects thereof are described in detail below.

[0044] see Figure 1A to Figure 9B Shown are cross-sectional views illustrating intermediate stages during fabrication of a preferred embodiment of the invention, wherein like numerals refer to like components throughout the views and illustrated embodiments of the invention. The preferred embodiment of the present invention uses the selective growth of source / drain regions as an example. Those skilled in the art will appreciate that the methods discussed are applicable to the selective epitaxial gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com