Stepped and repeated illuminating and nano-imprinting device

A nano-imprint and pressure technology, which is applied in the direction of optics, opto-mechanical equipment, and photoplate-making process on patterned surfaces, can solve the problems of inability to make overprint multi-layer nanostructure graphics, imperfect equipment technology, and poor alignment and overprinting accuracy. High-level problems, to achieve the effect of large imprinting effective area, low price and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

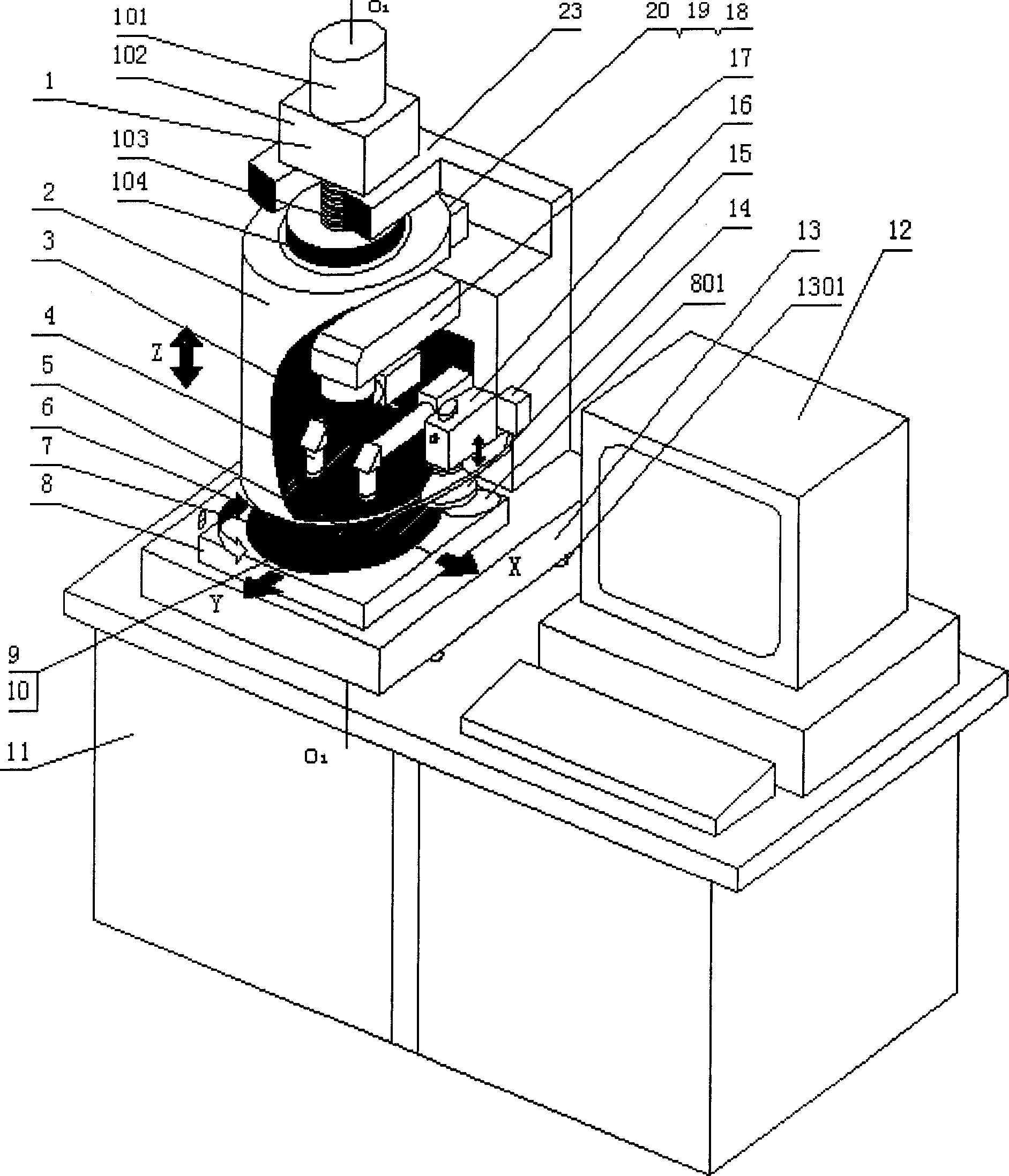

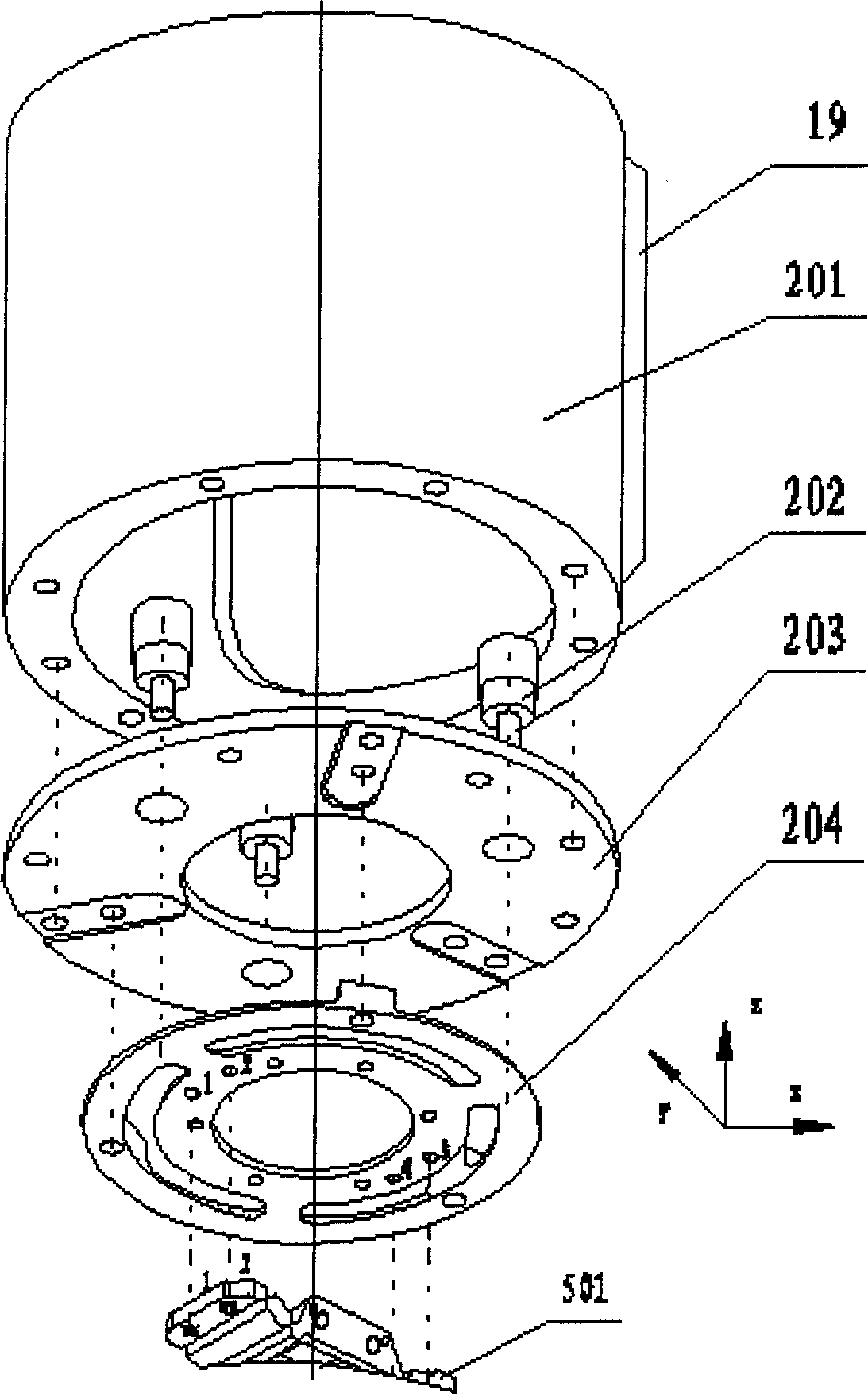

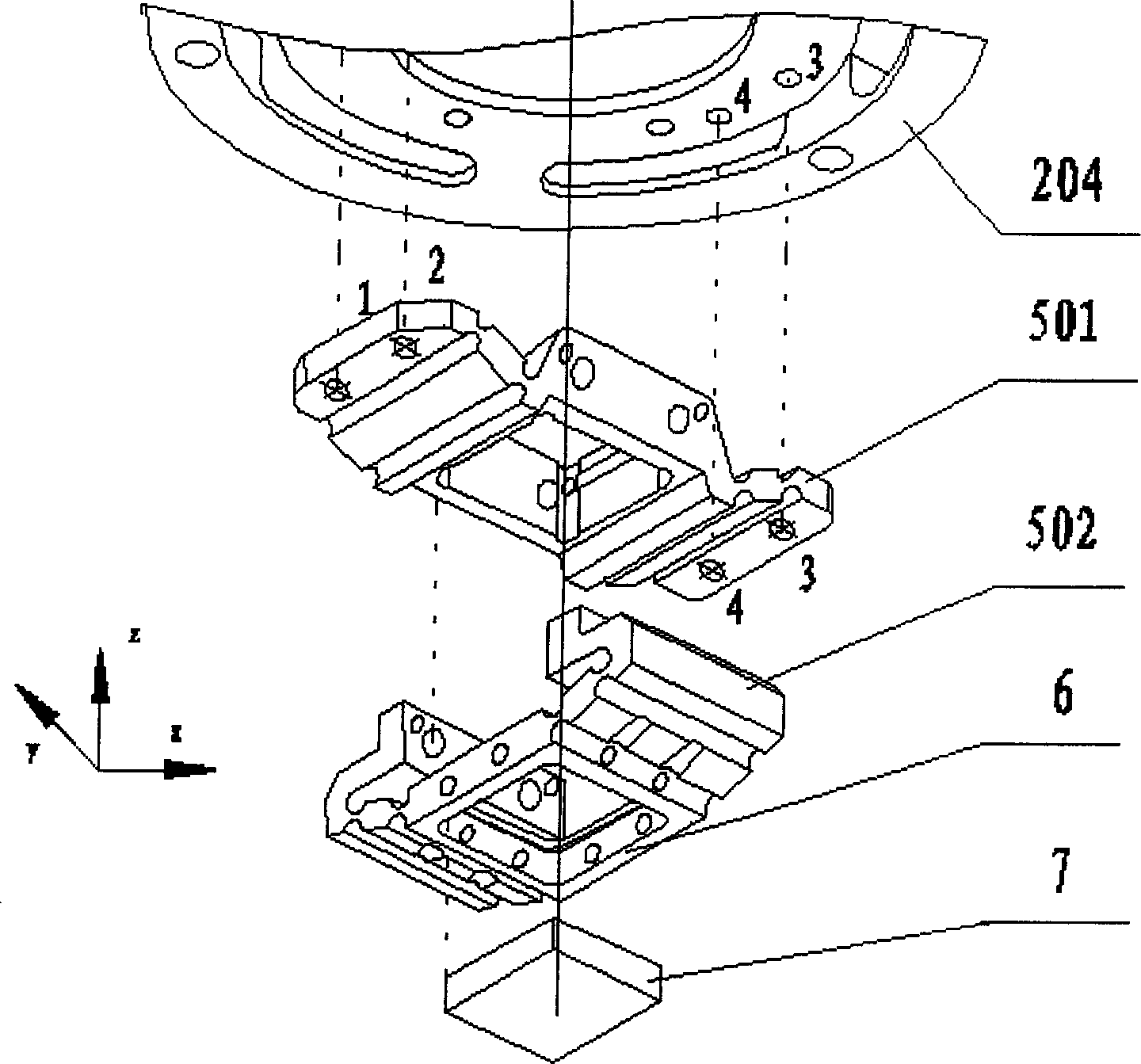

[0036] Such as figure 1 As shown, the present invention consists of a pressure drive system 1 composed of a motor, motor drive and transmission, a Z-direction calibration mechanism 2, a dual-channel CCD alignment system 4, an inclination calibration mechanism 5, a die chuck 6, a die 7, XYθ workpiece table 8, substrate 9, substrate support leveling system 10, large machine cabinet 11, computer system 12, main machine base plate 13, air seal 14, droplet device 15, air seal seat 16, purple light uniform illumination The system 17, the Z-direction measurement sensor 18, the Z-direction linear guide including the inner guide rail 19 and the outer guide rail 20, the Z-direction lifting and lower movement limiters 21 and 22 at both ends, and the frame 23 are composed of parts. The large base plate 13 of the main machine is placed on the large table of the large machine cabinet 11 through the vibration isolation pad 1301, and the large machine cabinet 11 is placed including the consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com