Ink jet recording sheet

A recording sheet, inkjet technology, applied in the direction of copying/marking method, printing, printing device, etc., can solve the problems of strong shrinkage, brittle strength, easy peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0133] In 100 parts of fine silica dispersion liquid A, mix 0.5 part of a 10% aqueous solution of sodium chloride and polyvinyl alcohol (manufactured by Kuraray Co., Ltd., trade name: PVA-140) with a degree of saponification of 98.5% and a degree of polymerization of 4000. 40 parts of 10% aqueous solution were formulated into a coating with a solid content concentration of 17.1% containing 0.25 parts of sodium chloride and 20 parts of polyvinyl alcohol relative to 100 parts of silica, and ion-exchanged water was added to make the concentration 16.0%. The main components and pH of the paint are shown in Table 1. The paint bar is coated on the support body to the coating amount is 20g / m in terms of dry mass 2 . This film was dried at 120° C. to form a porous ink receiving layer.

[0134] Then, on the ink-receiving layer, bar coating was performed by mixing 22 parts of a 10% aqueous solution of polyvinyl alcohol having a degree of saponification of 98.5% in 100 parts of cationi...

Embodiment 2

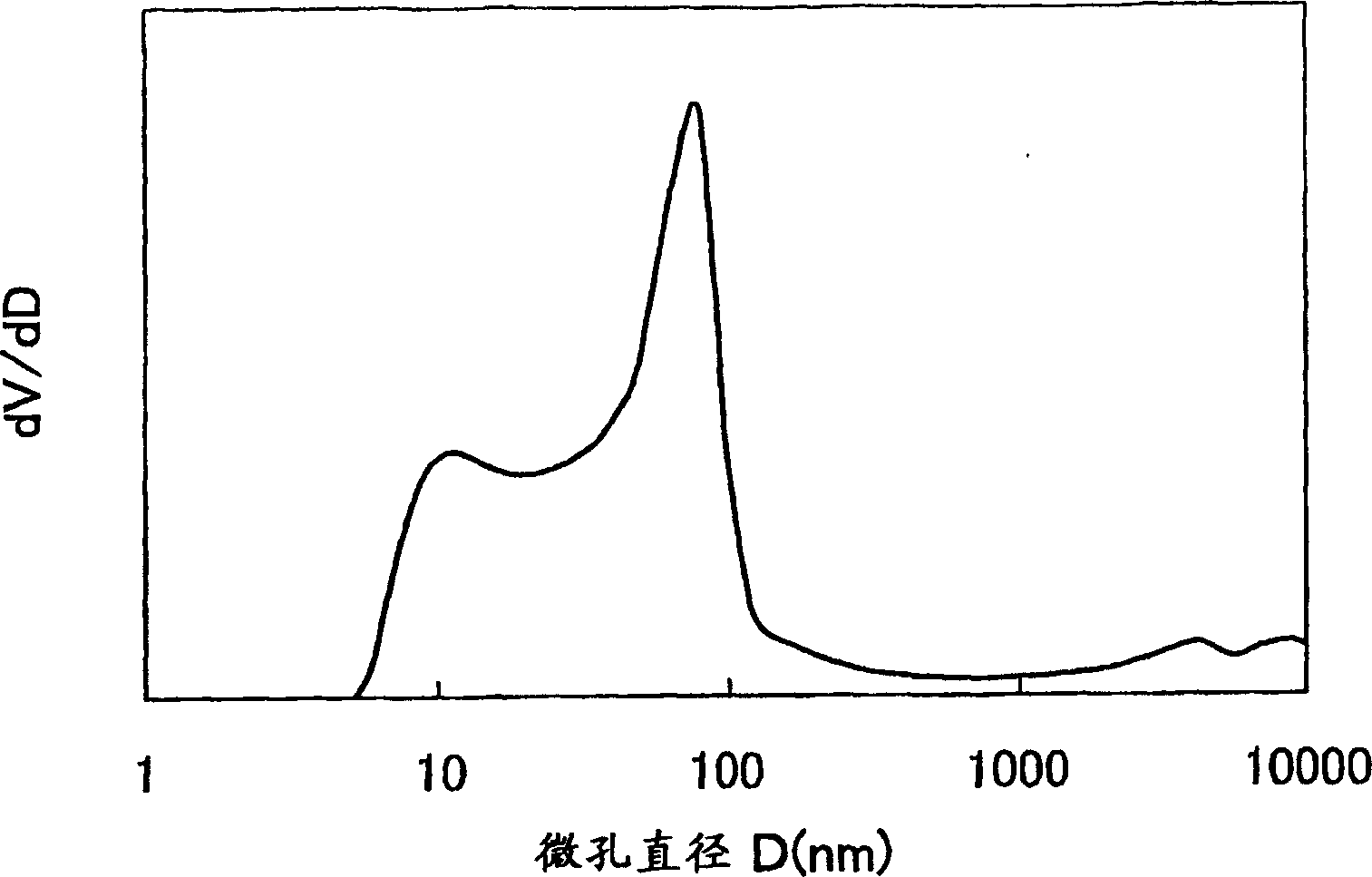

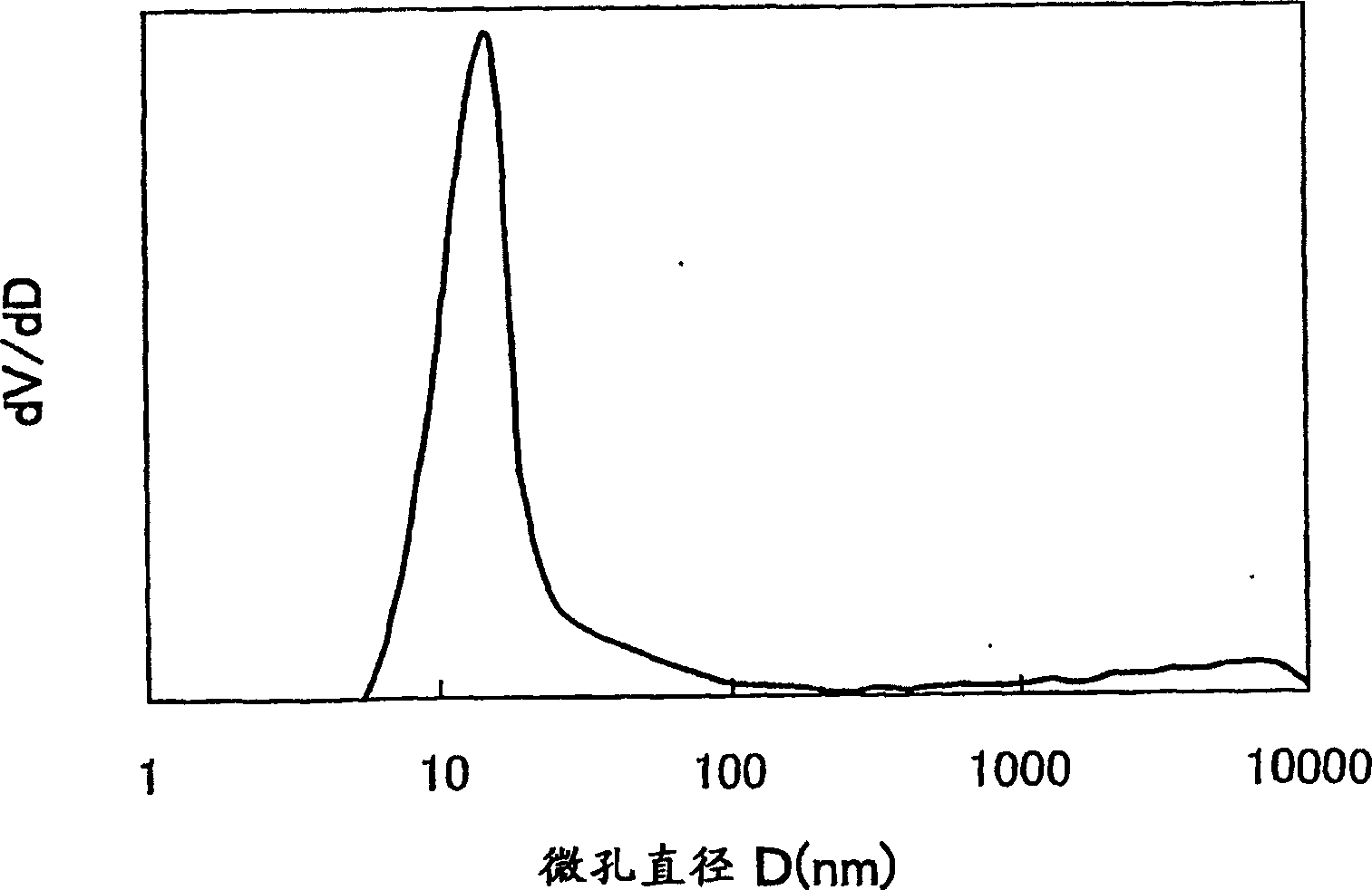

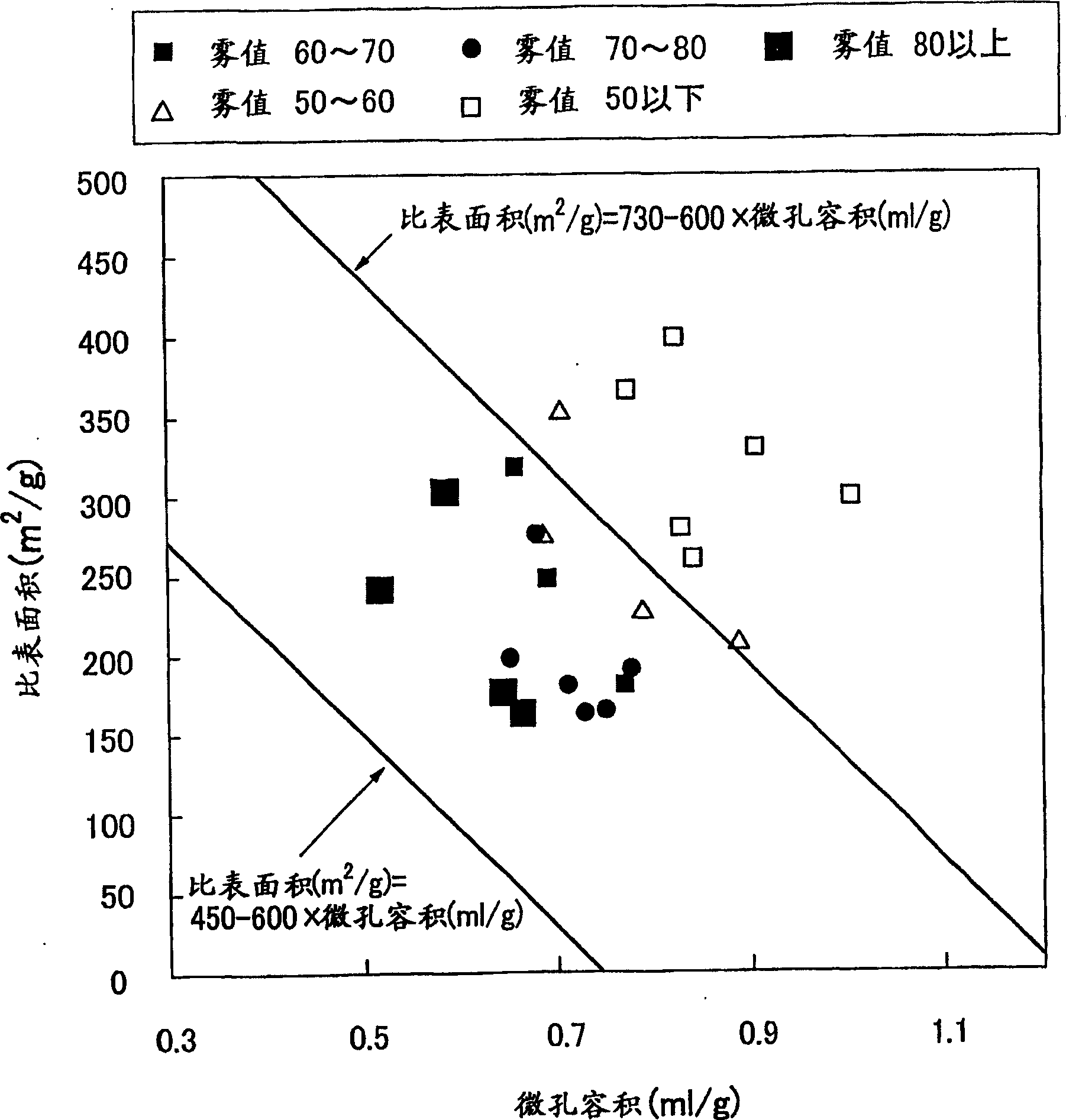

[0158] In 100 parts of fine silicon dioxide dispersion liquid A, mix 0.5 part of 10% aqueous solution of sodium sulfate and 40 parts of 10% aqueous solution of polyvinyl alcohol used in Example 1, be formulated to contain 0.25 parts of sodium sulfate relative to 100 parts of silicon dioxide 1. The solid content concentration of 20 parts of polyvinyl alcohol is the coating of 17.1%, and it is the coating of 16.0% to use to add ion-exchanged water dilution concentration, except that, with the same method as embodiment 1, porous ink receiving layer and Gloss-developing layer to produce an inkjet recording sheet. Table 1 shows the main components, pH, and lamination method of the glossy layer. Table 2 shows the pore distribution, cracks, film surface pH, and inkjet recording sheet quality of the porous ink receiving layer.

Embodiment 3

[0160] In 100 parts of fine silica dispersion liquid A, 1 part of a 10% aqueous solution of sodium sulfate and 10 parts of polyvinyl alcohol (manufactured by Kuraray Co., Ltd., trade name: PVA-635) with a saponification degree of 95.0% and a polymerization degree of 3500 were mixed. 40 parts of aqueous solution, prepared as relative to 100 parts of silicon dioxide, containing 0.5 parts of sodium sulfate and 20 parts of polyvinyl alcohol, with a solid content concentration of 17.1%, and adding ion-exchanged water to dilute the coating with a concentration of 16.0%. In addition, in the same manner as in Example 1, a porous ink-receiving layer and a glossy layer were provided to produce an inkjet recording sheet. Table 1 shows the main components, pH, and lamination method of the glossy layer. Table 2 shows the pore distribution, cracks, film surface pH, and inkjet recording sheet quality of the porous ink receiving layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com