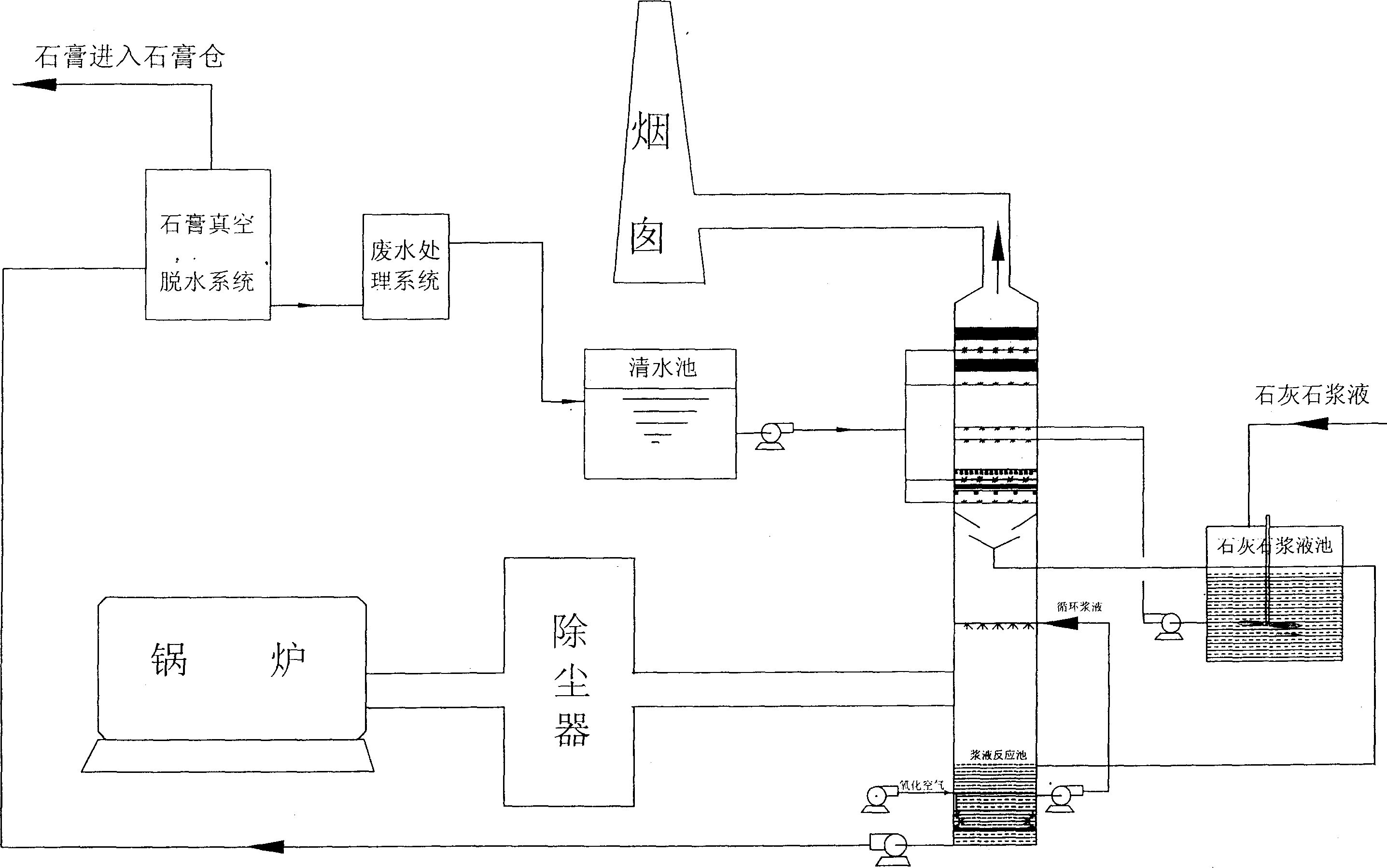

Flume gas desulfuration method and composite circulated convection absorbing tower

A compound cycle and absorption tower technology, applied in the field of flue gas desulfurization, can solve the problems of resource waste, difficult disposal, high operating costs, etc., and achieve the effect of increasing the surface area of slurry, eliminating flue gas pollution, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

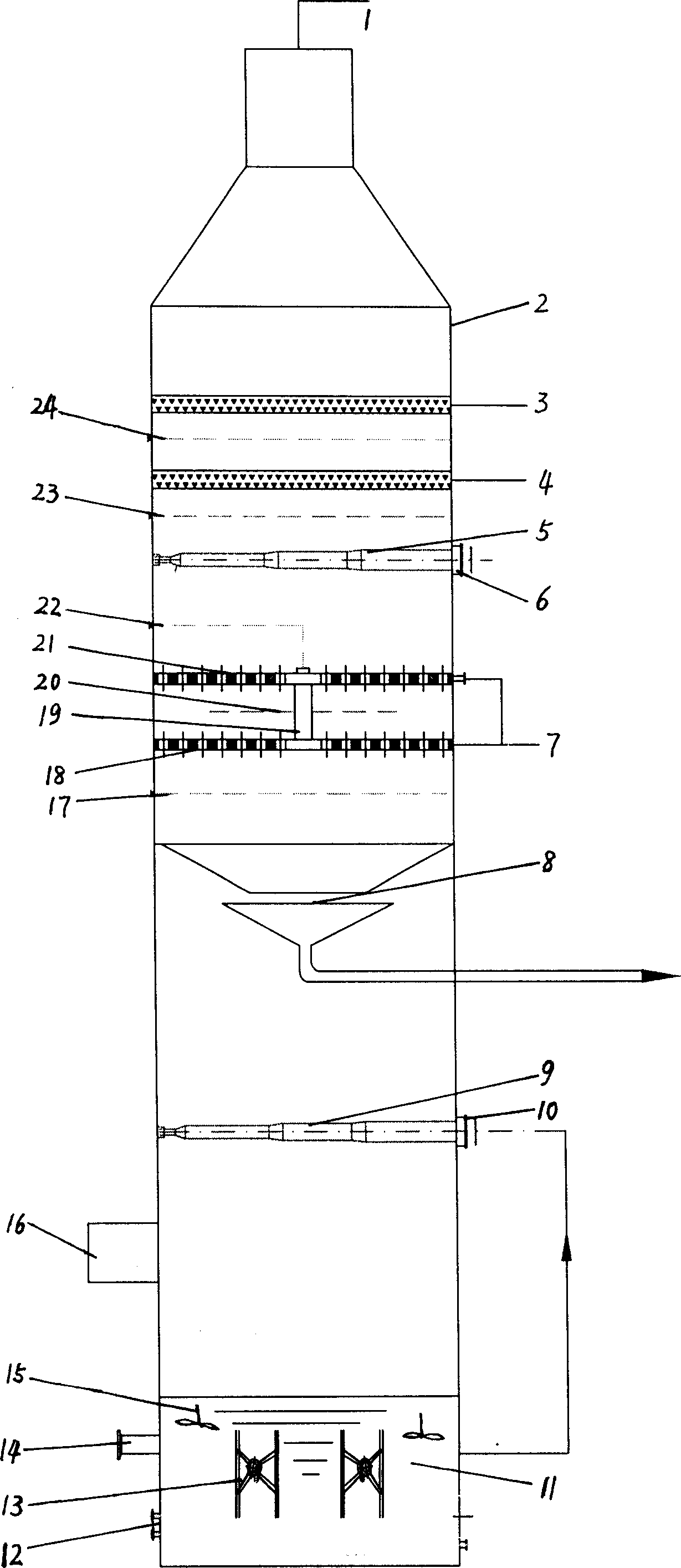

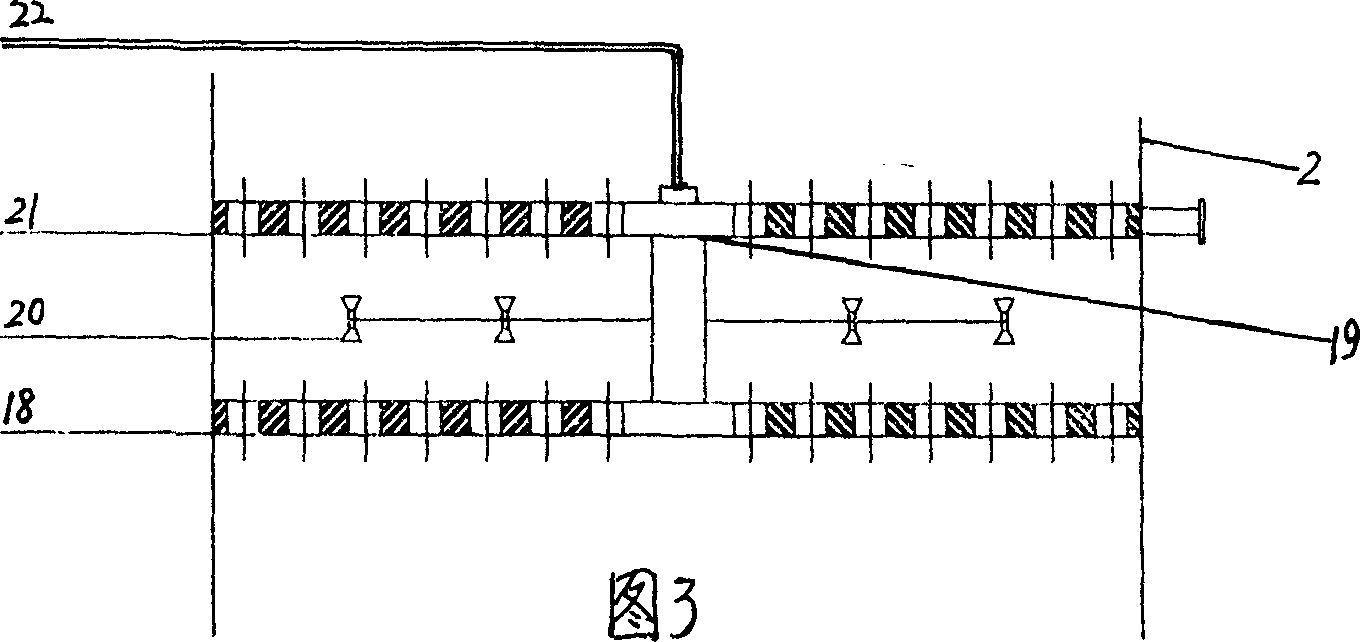

[0031] The compound cycle convection absorption tower has a slurry reaction tank 11 in the bottom of the tower tube 2 with a flue gas outlet 1 at the upper end, and there is a smoke on the tower tube 2 between the slurry reaction tank 11 and the lower circulation slurry spray device 9 located above. The air inlet 16, the lower circulation slurry spray device 9 connected to the lower circulation slurry inlet 10 on the tower tube 2, in the tower tube 2 above, there are funnel liquid collection return device 8, composite controllable flow blocking device 7, upper circulation slurry The spray device 5, the "V" shaped lower demister 4 and the upper demister 3, the upper circulation slurry inlet 6 on the tower 2 communicates with the upper circulation slurry spray device 5, and the composite controllable flow blocking device 7 The rotatable upper sieve plate 21 and the lower sieve plate 18 are connected by a bracket 19, and the bottom of the upper sieve plate 3, the lower sieve plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com