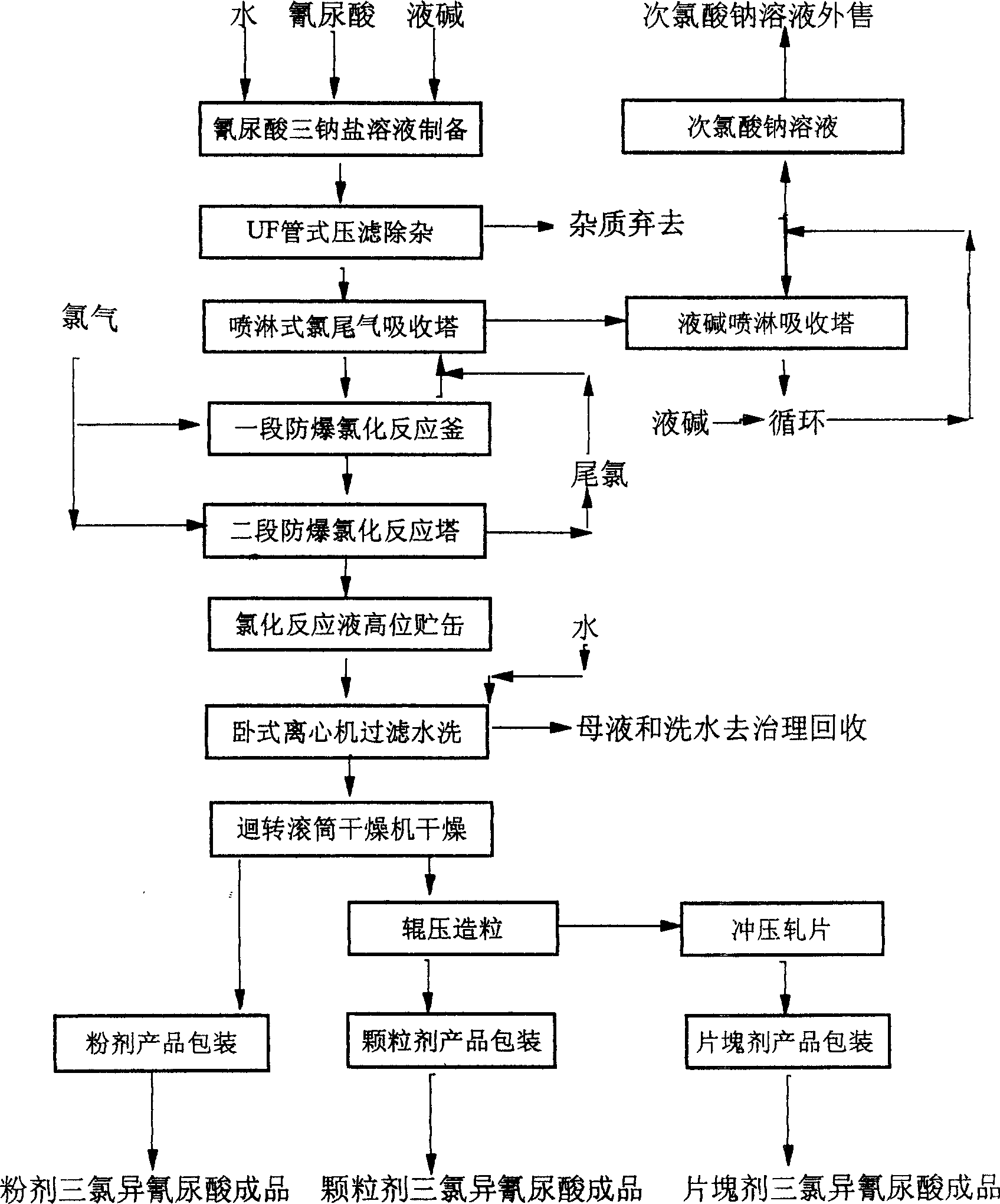

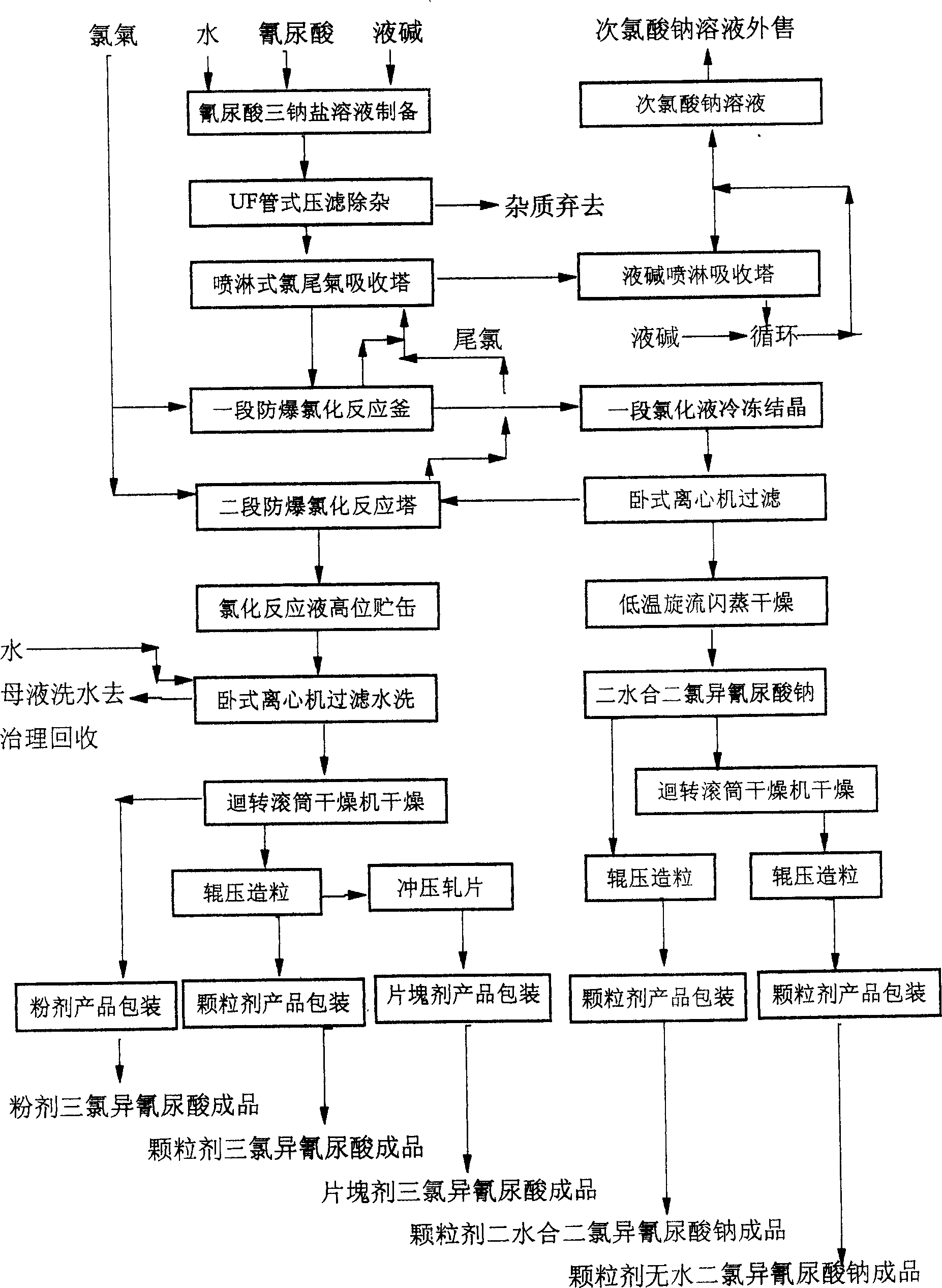

One-step two-phase continuous production of trichloro-isocyanuric acid

A technology of trichloroisocyanuric acid and cyanuric acid, applied in the fields of botanical equipment and methods, chemicals for biological control, biocides, etc., can solve the problem of low sodium chloride content, complicated operation, long production process, etc. The problem is to achieve the effect of reducing acetone insoluble impurities, easy operation and control, and saving caustic soda and chlorine gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Production of trichloroisocyanuric acid: (annual output of 3,000 tons of trichloroisocyanuric acid)

[0036] 1. Preparation of trisodium cyanurate solution:

[0037] In a 45 cubic meter stainless steel trisodium cyanurate dissolution reactor with stirring, thermometer, feeding port and jacket heat exchange, add 28565 kg of water, and add 3000.0 kg of cyanuric acid with fine powder content ≥ 98.5% under stirring, and stir to make It became a homogeneous slurry suspension. Under the condition of keeping the reaction temperature not higher than 35°C under stirring, slowly add 14689 kg of 20% liquid caustic soda within 6 to 6.5 hours. The speed of adding liquid caustic soda should be fast first and then slow. liters / hr, and the speed of adding liquid caustic soda in the middle is controlled at 1800 liters / hr; later, it is reduced to 800-820 liters / hr. After the addition of liquid caustic soda, keep the reaction at 36-38°C and stir to dissolve all the materials. After ...

Embodiment 2

[0074] (1) Production of trichloroisocyanuric acid (annual output of 5,000 tons of trichloroisocyanuric acid)

[0075] 1. Preparation of trisodium cyanurate solution:

[0076] In a 45 cubic meter stainless steel trisodium cyanurate dissolution reactor with stirring, thermometer, feeding port and jacket heat exchange, add 28008 kg of water, add 3000.0 kg of fine powder content ≥ 98.5% cyanuric acid under stirring, and stir to make It became a homogeneous slurry suspension. Put warm water into the jacket, keep the reaction temperature not higher than 35°C under stirring, slowly add 15595 kg of 20% caustic soda solution within 6 to 6.5 hours, the speed of adding liquid caustic soda should be fast at first and then slow. The speed of liquid caustic soda is about 3200 liters / hr, and the speed of adding liquid caustic soda in the middle is controlled at 1800 liters / hr; later it is reduced to 800-820 liters / hr. After adding the liquid caustic soda, keep the reaction temperature at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com