Contacts fabric using heterostructure of metal/semiconductor nanorods and fabrication method thereof

A heterostructure, nanorod technology, applied in nanostructure fabrication, semiconductor/solid-state device fabrication, semiconductor devices, etc., can solve the problems that no one has studied to control the properties of nano-contact fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0023] The contact fabric using the heterostructure of metal / semiconductor nanorods and the preparation method thereof of the present invention will be described in detail below with reference to the accompanying drawings. A detailed description of known technologies or structures would obscure and obscure the subject matter of the present invention, so details are not repeated here. The technical terms defined based on the functions of the corresponding elements used throughout the specification and claims may vary depending on a user's or operator's intention or specific circumstances. Therefore, the definitions of these technical terms should be determined based on the context of the specification and claims.

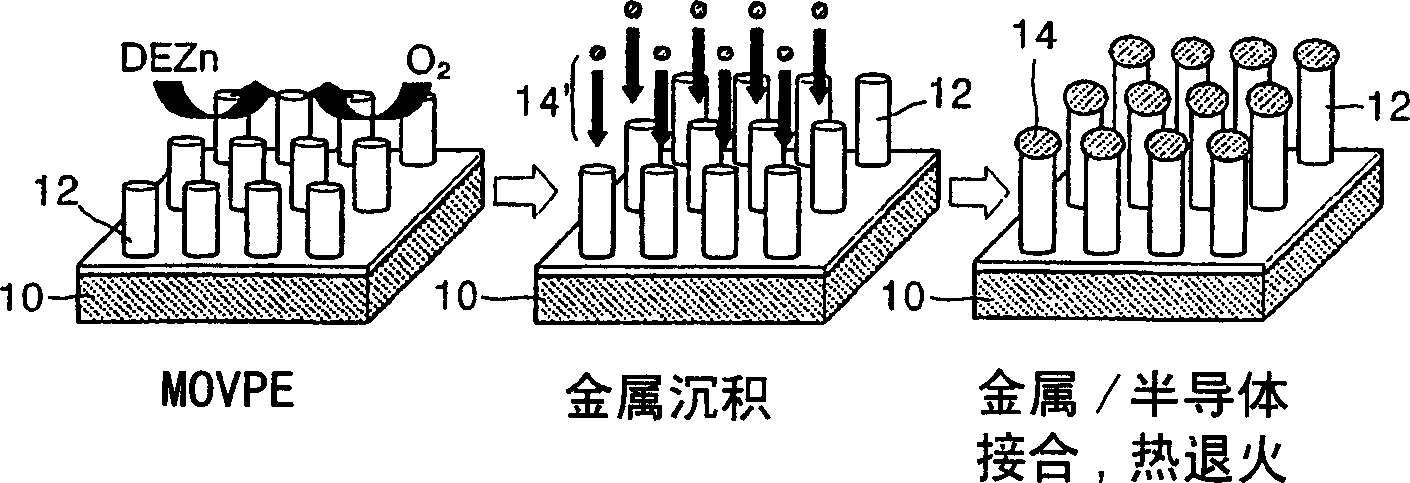

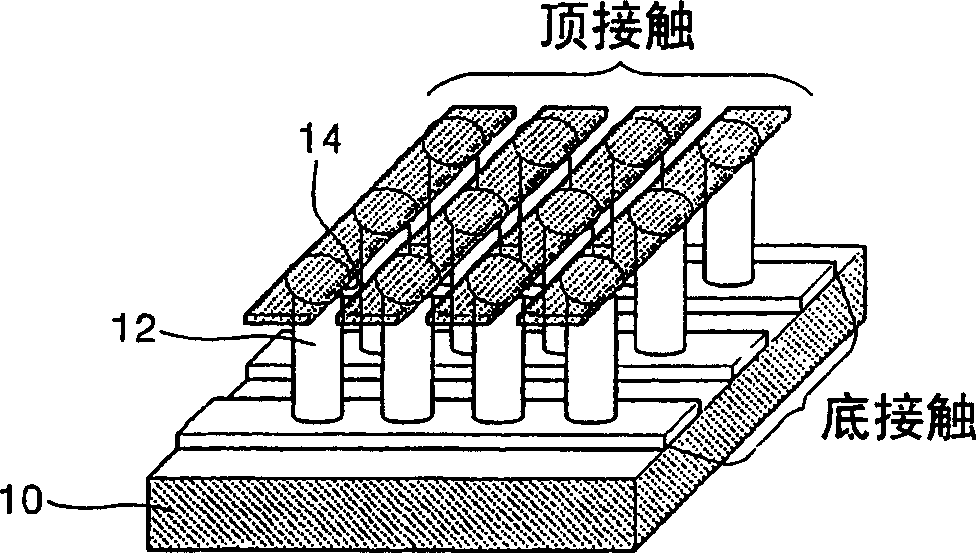

[0024] refer to figure 1 , gives an overview illustrating the inventive contact fabric using a heterostructure of metal / semiconductor nanorods and its preparation method. At this time, ZnO / semiconductor nanorods 12 are grown on the substrate 10 in a certain directi...

Embodiment 1

[0034] Growth of metal / ZnO nanorods (see figure 1 )

[0035] Gold and titanium / gold are deposited on commonly used ZnO / semiconductor nanorods aligned in a certain direction using thermal evaporation or electron beam evaporation. Here, gold was deposited to a thickness of about 20 nm, and titanium / gold was deposited to a thickness of 10 nm and 20 nm, respectively. The accelerating voltage and emission current of the electron beam used for evaporating metals are 4-20kV and 40-400mA, respectively. The pressure of the reactor is 10-5mmHg when depositing the metal, and the temperature of the substrate is room temperature. The ZnO nanorod arrays were examined using electron microscopy before and after metal deposition. It was found that the metal had been selectively deposited onto the tips of the nanorods without significant changes in the diameter and current state of the nanorods.

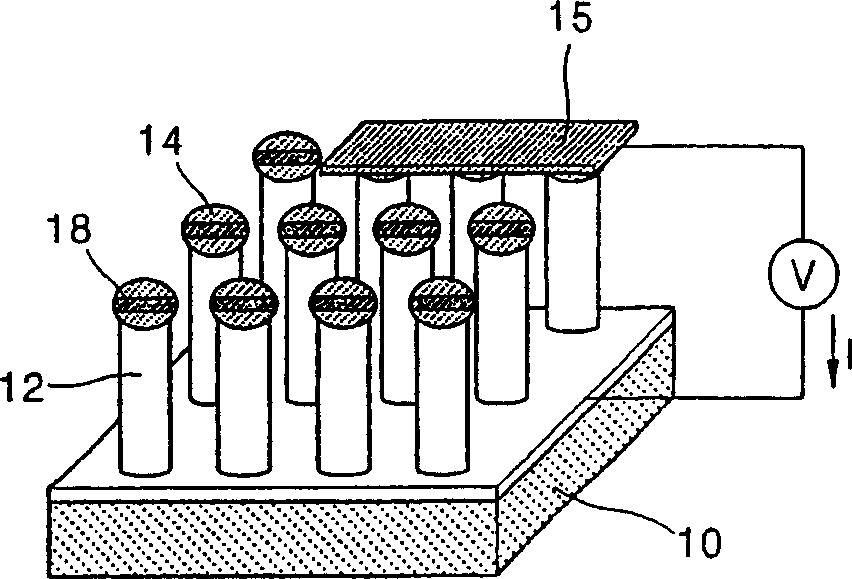

[0036] Determination of electrical properties of metal / zinc oxide nanorods (cf. Figure 4-6 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com