Aseptic plastic soft package material preparation process

A preparation process and sterile plastic technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of waste of non-ferrous metal resources, difficulty in recycling packaging bottles, and fragile packaging, so as to reduce waste and ensure quality , The effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

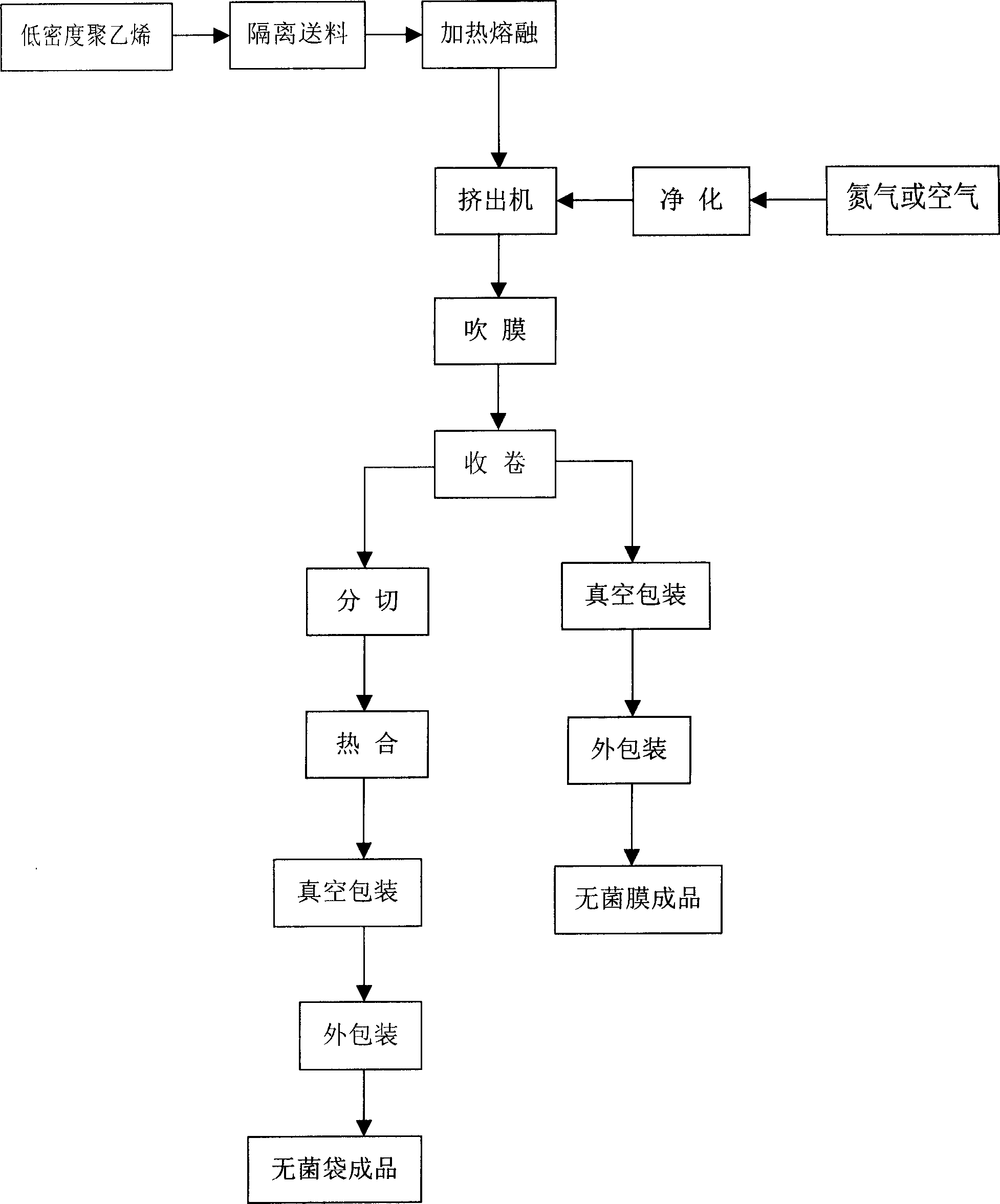

[0016] like figure 1 As shown, domestic or imported film blowing units are selected, and the air purification system is first turned on before production, and the personnel entering the operation area are strictly sterilized and purified, and the clean area is disinfected and sterilized, so that the environment of the clean area (film blowing unit and operating environment) Meet the following standards (i.e. ten-thousand level standard): temperature: 18-26 °C, humidity: 45-65%, dust particles ≥ 0.5 μm per m 2 No more than 350,000 dust particles ≥ 5 μm per m 2 No more than 2000 planktonic bacteria per m 3 Not more than 100, sedimentation bacteria per m 3 No more than 3; then filter the required nitrogen through a filter purifier, so that the filtered and purified nitrogen reaches the 100-level standard, that is: dust particles ≥ 0.5 μm per m 2 No more than 3,500 dust particles ≥ 5 μm shall not be detected, planktonic bacteria per m 3 Not more than 5, sedimentation bacteria ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com