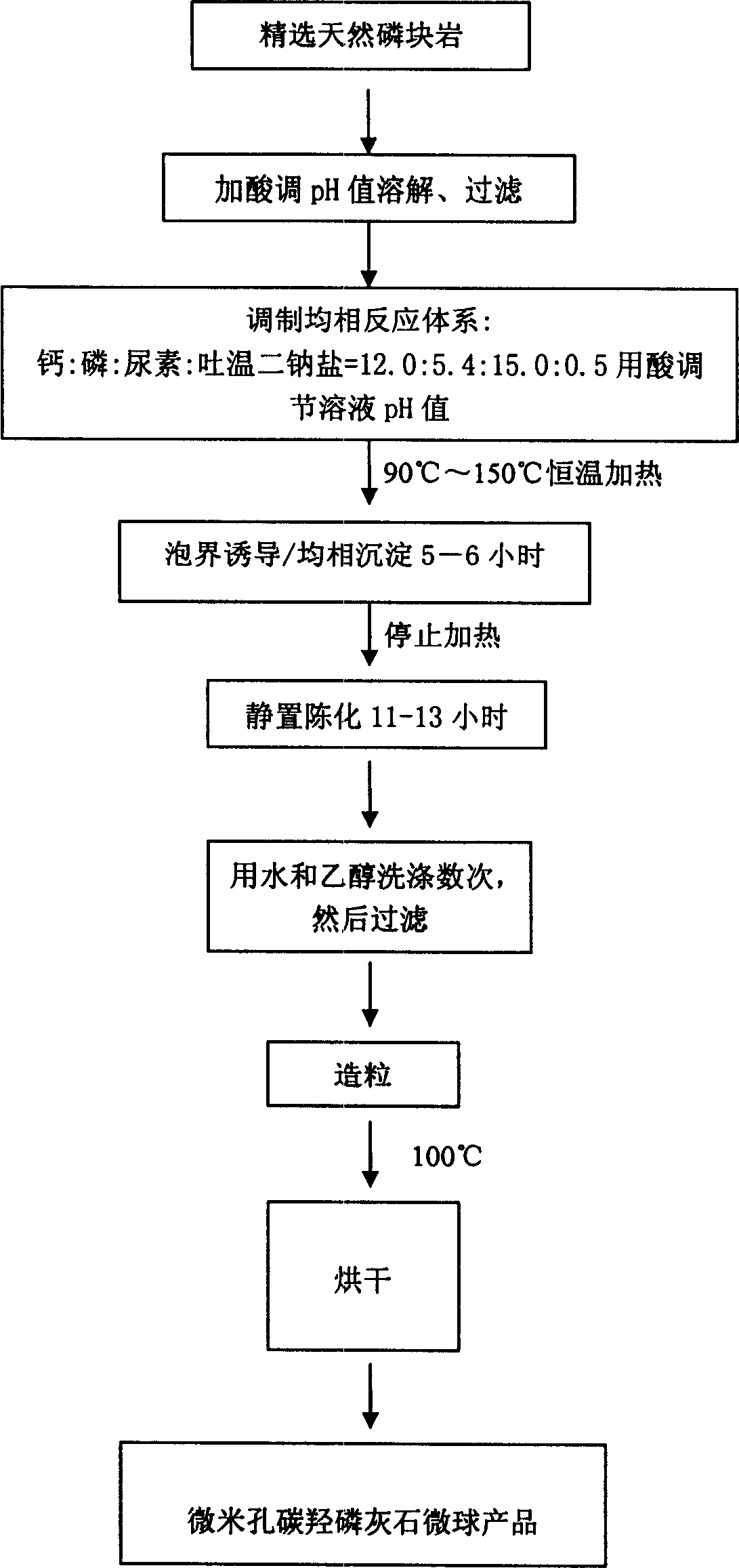

Production process of microporous carbon hydroxyapatite

A technology of porous carbon hydroxyapatite and production method, which is applied in the field of preparation of micron porous carbon hydroxyapatite, which can solve the problems of excessive pore size, expensive raw materials, high sintering temperature, etc., and achieve the effect of strong curing ability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] First select natural phosphorite, add hydrochloric acid to adjust the pH to 5.5, subject to the complete dissolution of phosphorus and calcium, filter to remove insoluble impurities, the impurities are mainly quartz and clay, add appropriate amount of urea and ethylenediamine tetramine to the filtrate Acetic acid (EDTA) solution, make in the solution by weight percentage: calcium: phosphorus: urea: the ratio of EDTA=12.0: 5.4: 15.0: 0.5, adjust solution pH to 4.5 with hydrochloric acid, as the criterion that does not produce precipitation, put into Make a homogeneous system in an autoclave, heat it to 95°C to 100°C, urea slowly hydrolyzes to release hydroxyl groups and carbonate groups, and releases a large number of bubbles at the same time. After reaching supersaturation, bubble boundary induction / homogeneous precipitation reactions begin to occur. After 5 hours Stop heating, stand and age for 12 hours, wash, filter, granulate, and dry to obtain carba-hydroxyapatite wi...

Embodiment 2

[0010] First select 1Kg of natural phosphorite, add hydrochloric acid to adjust the pH to 5.5, subject to the complete dissolution of phosphorus and calcium, filter to remove insoluble impurities, the impurities are mainly quartz and clay, add 0.5Kg of urea and 0.0167kg of EDTA to the filtrate solution, adjust the pH of the solution to 4.5 with hydrochloric acid, subject to no precipitation, put it in an autoclave to make a homogeneous system, heat it to 140°C~145°C, the urea will slowly hydrolyze to release hydroxyl and carbonate, and release a lot of bubbles at the same time , after reaching supersaturation, bubble boundary induction / homogeneous precipitation reaction starts to occur, stop heating after 5 hours, let stand and age for 12 hours, wash, filter, granulate, dry, and finally obtain carbon with a pore size of 0.5 μm mixed with carbonate Hydroxyapatite is microspherical in shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com