Treating process of amino acid fermenting effluent

A technology for fermentation waste liquid and treatment process, which is applied in the direction of aerobic process treatment, sustainable biological treatment, organic fertilizer, etc., and can solve the links without production benefits, economic losses of enterprises, and the inability of schools and residents to study and live normally. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] This technology was first applied to Baoji Fufeng Fermentation Biotechnology Co., Ltd. of Shandong Fufeng Fermentation Group. The main product of Baoji Fufeng Fermentation Biotechnology Co., Ltd. is glutamic acid. In the early stage of production, because the fermentation waste liquid could not be completely treated, it could not pass the acceptance of the environmental protection department, forcing the factory to limit production, stop production, and rectify within a time limit until it reached the standard. After adopting this treatment process, the fermentation waste liquid has been thoroughly treated, successfully passed the inspection and acceptance of the environmental protection department, and won precious time for the enterprise. It was put into production that year, bringing a net profit of more than 200 million yuan, and achieved obvious results. economic and environmental benefits.

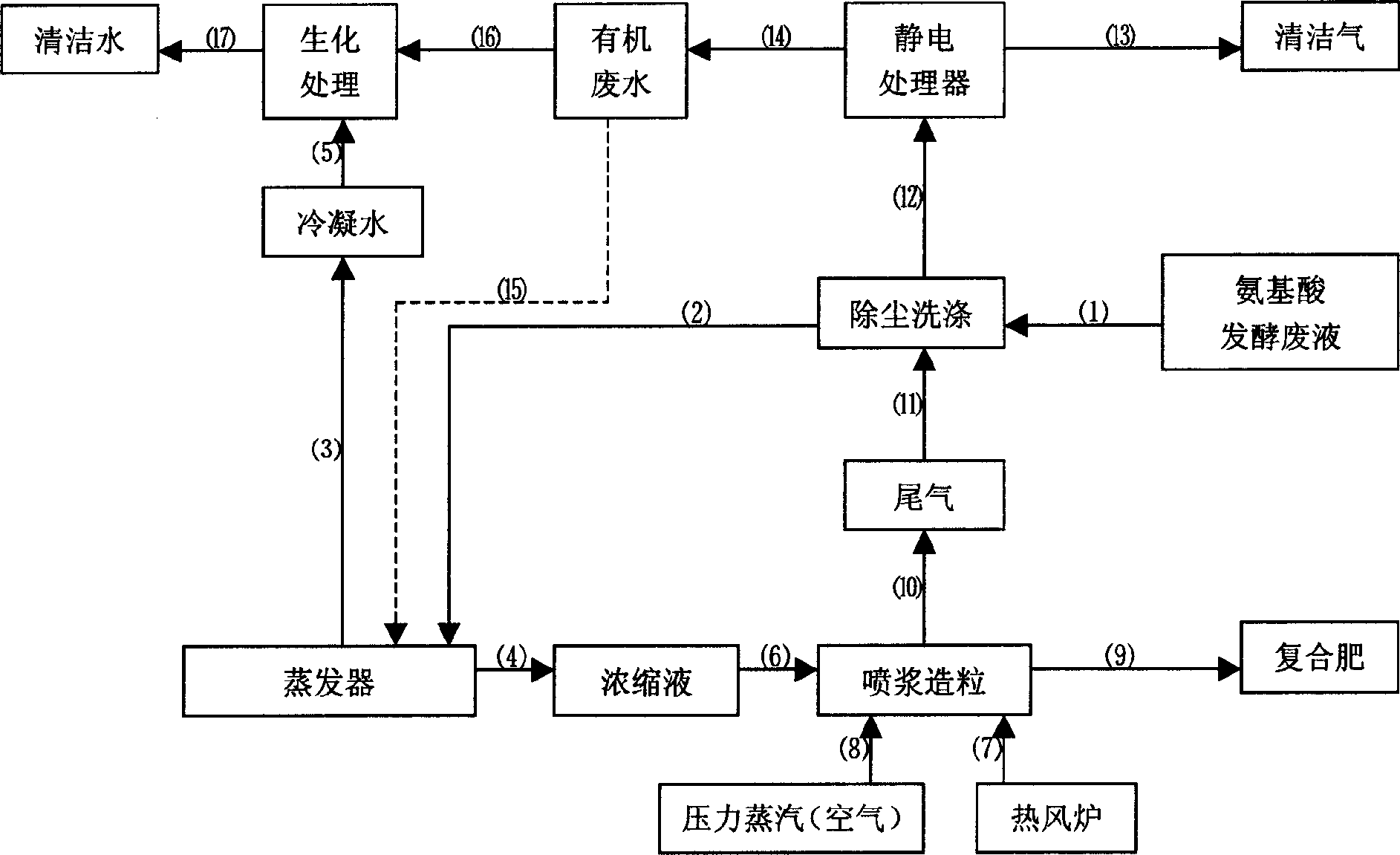

[0035] The process flow is like the instruction manual (with attached pic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com