Zhangyanming capsule and preparing process

A technology for capsule preparation and blindness, which is applied in the directions of capsule delivery, medical preparations containing active ingredients, and plant raw materials, etc., can solve the problems of unsightly appearance, slow dissolution rate of active ingredients, cumbersome coating process of sugar-coated tablets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

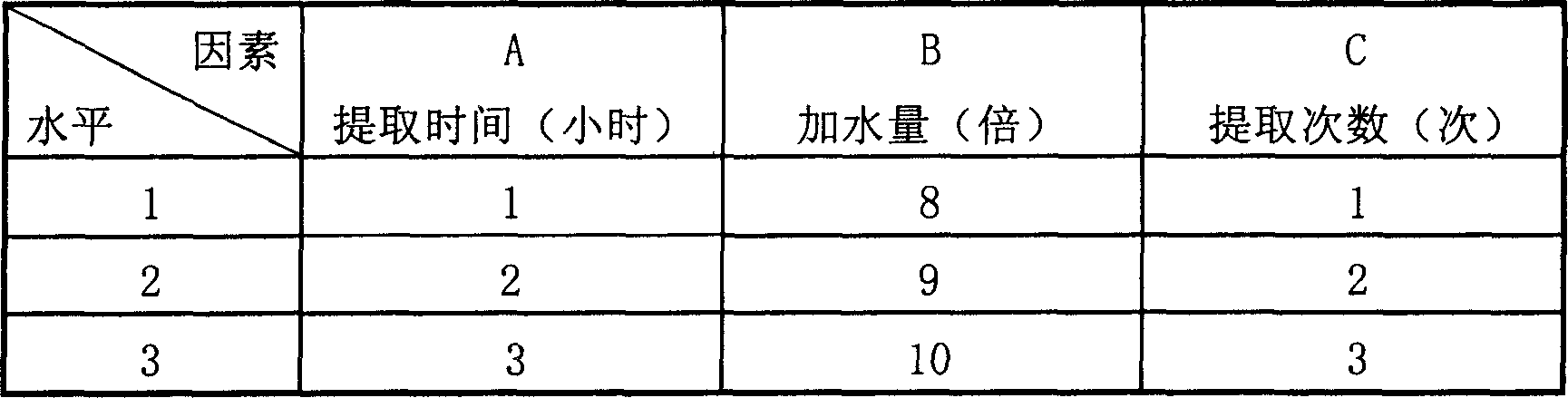

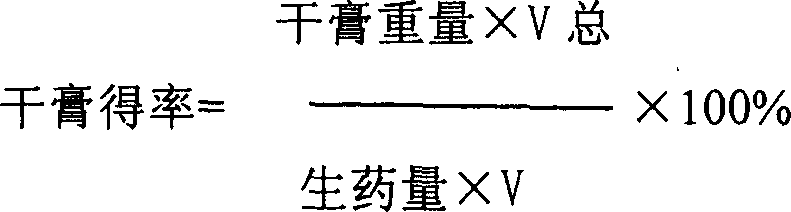

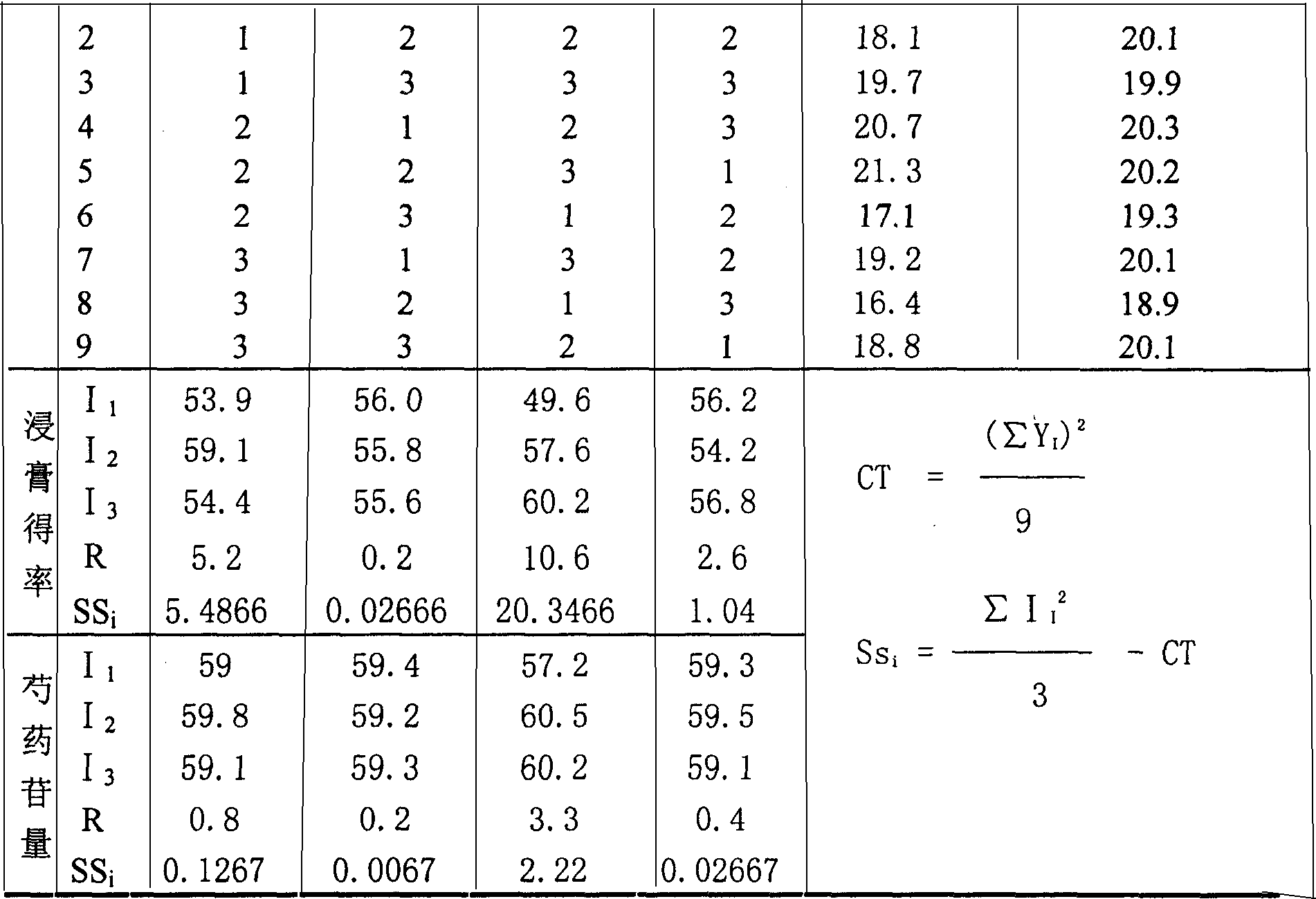

Method used

Image

Examples

Embodiment 1

[0069] The active ingredients of the present invention are: Acorus calamus 22.8g, Cassia seeds 30.6g, Cistanche cistanche 37.8g, Pueraria lobata root 37.8g, Celosia argentea 30.6g, Codonopsis pilosula 48.6g, Vinegrass 30.6g, Chinese wolfberry 48.6g, Plantago seed 37.8g , Radix Paeoniae Alba 45.6g, Dogwood 24.6g, Licorice 22.8g, Cuscuta Seed 61.2g, Cimicifuga 7.8g, Endocarp 37.8g, Chrysanthemum 37.8g, Dense Mongolian Flower 37.8g, Chuanxiong 30.6g, Polygonatum 37.8g, Rehmannia glutinosa 61.2g, Phellodendron amurense 30.6g, Astragalus 48.6g.

[0070] The above twenty-two flavors, cassia seeds, vine seeds, dodder seeds, green argentea, and plantain seeds are soaked in boiling water for 20 hours, then add the remaining Shichangpu 17 flavors and boil twice, each time for 2 hours, each time adding 8 Double the amount of water, filter, combine the filtrate, concentrate to a clear paste with a relative density of 1.35 measured at 60℃, vacuum dry at 60℃-70℃, vacuum degree 0.07-0.08Mpa, cru...

Embodiment 2-4

[0072] In order to verify and perfect the experimentally researched preparation process, in order to achieve the operability of production and the adaptability to the relevant equipment, we magnified the formulation prescription by 10 times to feed, and the best process and technical conditions obtained under laboratory conditions were studied. Carry out three batches of pilot studies and record in detail the key technological parameters. The quality inspection of three batches of pilot products was carried out, and the results are shown in Table 14.

[0073] Lot number

[0074] Quality

[0075] The above results show that the preparation process conditions of the Zhangyanming capsules are reasonable and feasible; the methods of extraction, concentration, drying and preparation are compatible with the scale-up production equipment; the quality of the prepared products is qualified and can be used for industrial production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com