Production of biological diesel oil

A production method, biodiesel technology, applied to the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve the problems of resource waste, disposal or incineration, and achieve the effects of reducing raw material costs, increasing income, and broadening raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

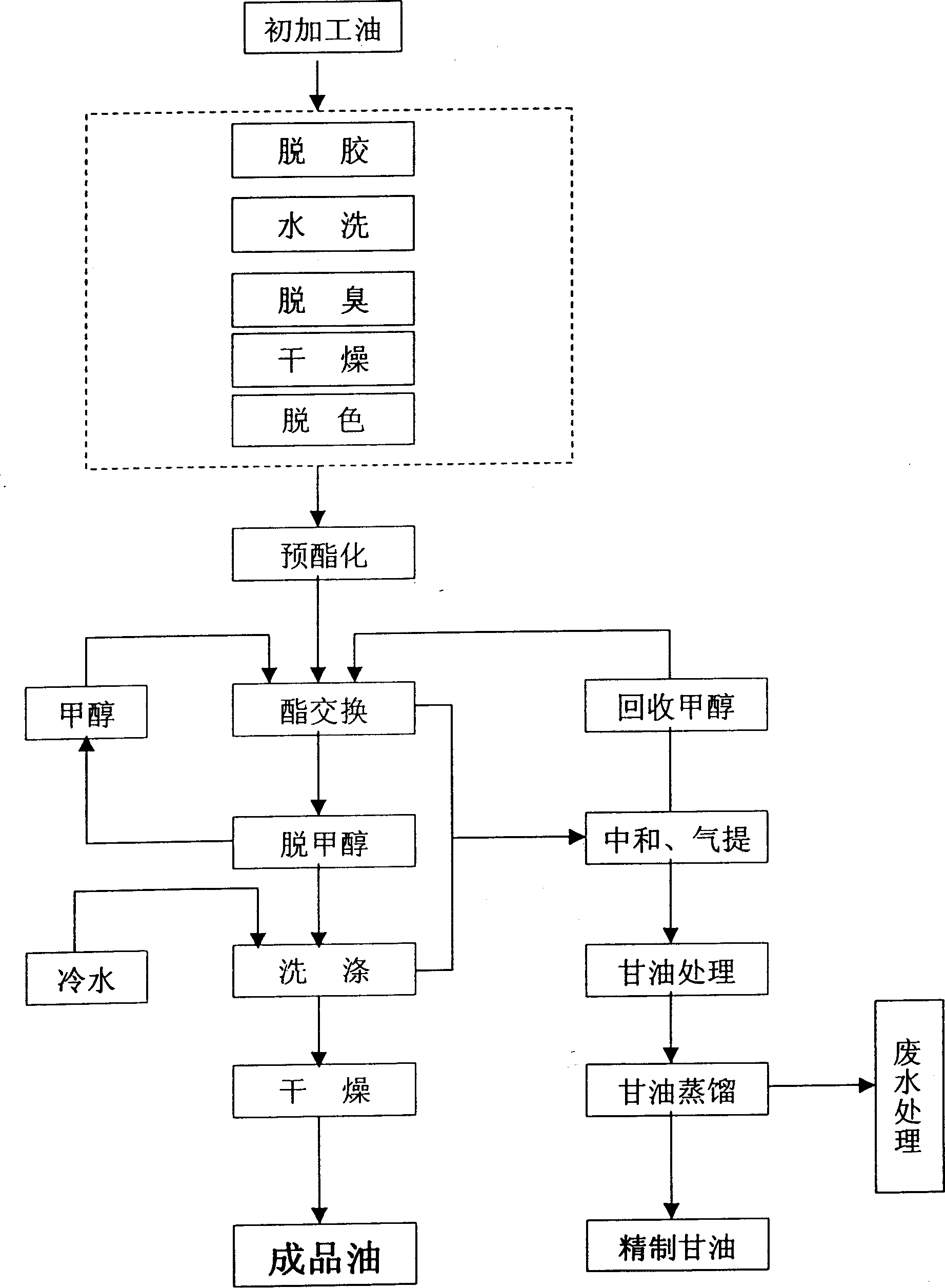

[0020] Such as figure 1 The technological process shown, take 1000 kilograms of camellia oleifera fruit, first remove the shell and peel of the camellia oleifera fruit, then crush and squeeze it to obtain the primary processed oil, reserve the residue after the primary processing, and degumming, deodorize, and degumming the primary processed oil Dehydration, decolorization and removal of harmful impurities are processed to obtain raw material oil and deodorized distillate; the raw material oil is prefabricated, then mixed with methanol, and then enters the reaction device. The reaction device is composed of three consecutive reactors, starting from the first The upper part of a reactor is fed into, the first reactor is filled with a solid catalyst strong base resin, and then enters the second reactor and the third reactor in turn, and the second reactor is filled with a solid catalyst strong base The third reactor is filled with liquid catalyst sodium methoxide. In this proces...

Embodiment 2

[0027] Such as figure 1 According to the process flow shown, 500 kg of castor beans and 500 kg of palm fruit are taken, and the castor beans and palm fruit are first removed from the shell, peeled, and then crushed and pressed to obtain primary processed oil, and the residue after primary processing is used for later use , degumming, deodorization, dehydration, decolorization and removal of harmful impurities are performed on the primary processed oil to obtain raw material oil and a deodorized distillate; the raw material oil is pre-fatified, then mixed with methanol, enters the reaction device, and reacts The device consists of three continuous reactors, which are fed from the upper part of the first reactor. The first reactor is filled with solid catalyst strong basic resin, and then enters the second reactor and the third reactor successively. The two reactors are filled with a solid catalyst strong basic resin, and the third reactor is filled with a liquid catalyst sodium...

Embodiment 3

[0034] Such as figure 1 The technological process shown, take 250 kilograms of hazelnuts, 250 kilograms of tung seeds, and 500 kilograms of linseeds, first shell and peel the hazelnuts, tungseeds and linseeds, and then crush and squeeze them to obtain the primary processed oil. The residue after primary processing is used for later use. The primary processed oil is subjected to degumming, deodorization, dehydration, decolorization and removal of harmful impurities to obtain raw material oil and a deodorized distillate; the raw material oil is pre-fatted and then mixed with ethanol , into the reaction device, the reaction device is composed of three consecutive reactors, fed from the upper part of the first reactor, the first reactor is filled with a solid catalyst strong basic resin, and then enters the second reactor and the second reactor in turn Three reactors, the second reactor is filled with solid catalyst strong basic resin, the third reactor is filled with liquid catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com