Process for preparing 5-sodium sulfo isophthalate

A technology of isophthalic acid and sodium sulfonate, applied in the preparation of sulfonic acid, organic chemistry, etc., can solve problems such as inability to solve quality and yield, and inability to industrialize production, so as to reduce raw material consumption, avoid pollution, and improve product yield. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

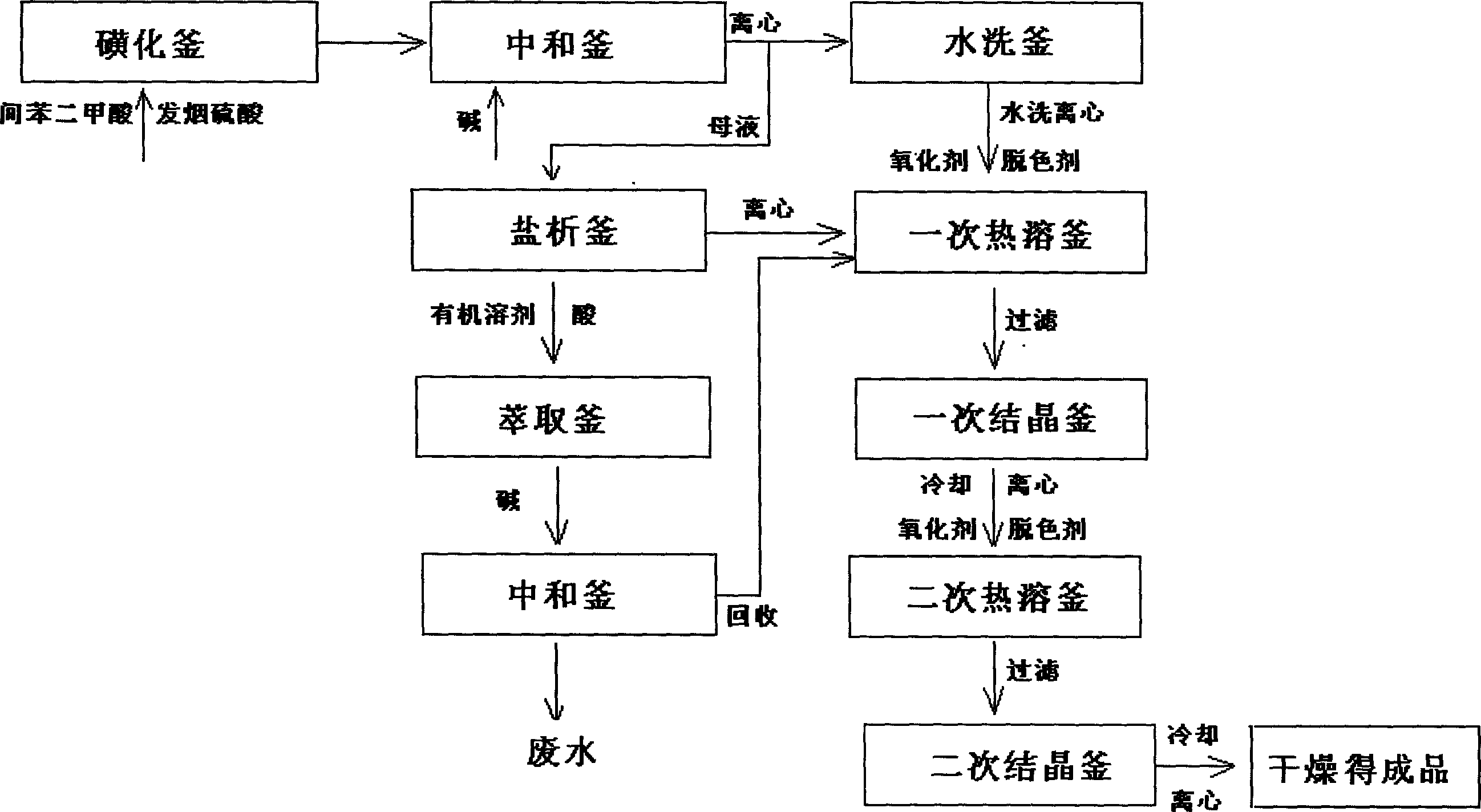

[0019] In conjunction with accompanying drawing, the present invention is further described:

[0020] According to the preferred molar ratio of 1: (1-1.5) isophthalic acid and fuming sulfuric acid react in the sulfonation kettle at 150-200°C for 5-10 hours, after the sampling reaches the end point of sulfonation, the sulfonation material Put it into the neutralization kettle, cool down to 100-130°C, add deionized water, and after cooling to room temperature, slowly add alkali, which can be sodium hydroxide, sodium carbonate, sodium bicarbonate, etc., and centrifuge after fully stirring the reaction. Add sodium sulfate to the mother liquor and centrifuge in the salting-out kettle, and return the centrifuged material to a heat-dissolving kettle, add toluene and sulfuric acid to the obtained salting-out mother liquor in the extraction kettle for extraction, the lower layer is the waste solution, and the upper layer solution is added to the neutralization kettle. Alkali neutraliza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com