Powder materials rapid forming system

A powder material, fast technology, applied in the field of powder material rapid prototyping system, can solve the problems of increasing the cost of powder material rapid prototyping, protecting gas affecting personal safety, affecting the quality of formed parts, etc., to facilitate rapid prototyping and eliminate spheroidization function, efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing and example.

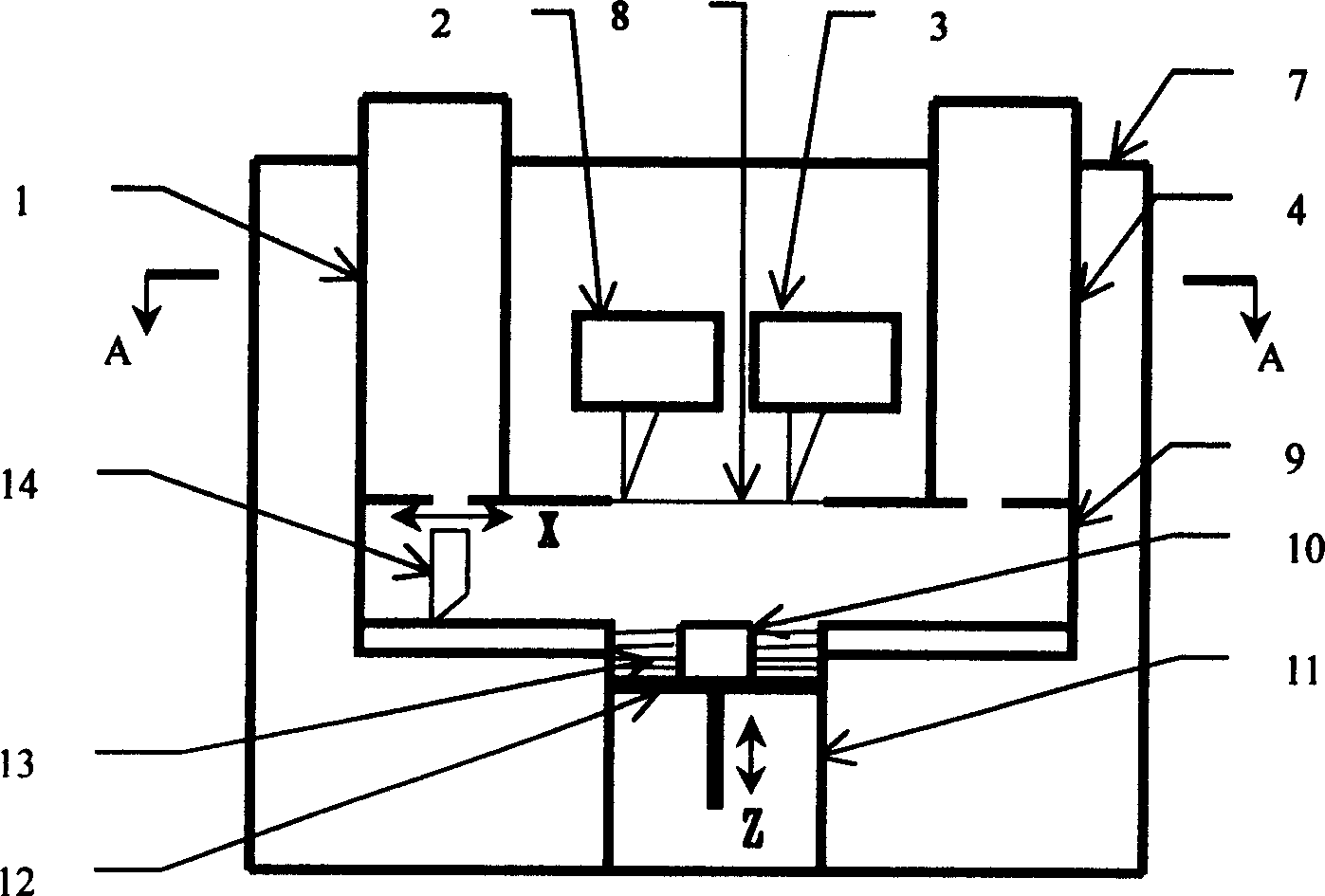

[0011] like figure 1 As shown, the system of the present invention consists of a processing space and two or more laser scanning devices. Wherein, the processing space 7 is composed of left and right powder falling devices 1, 4, a protective mirror group 8, a roller (or scraper) 14, a working chamber 9, a working cylinder 11 and a working cylinder piston 12.

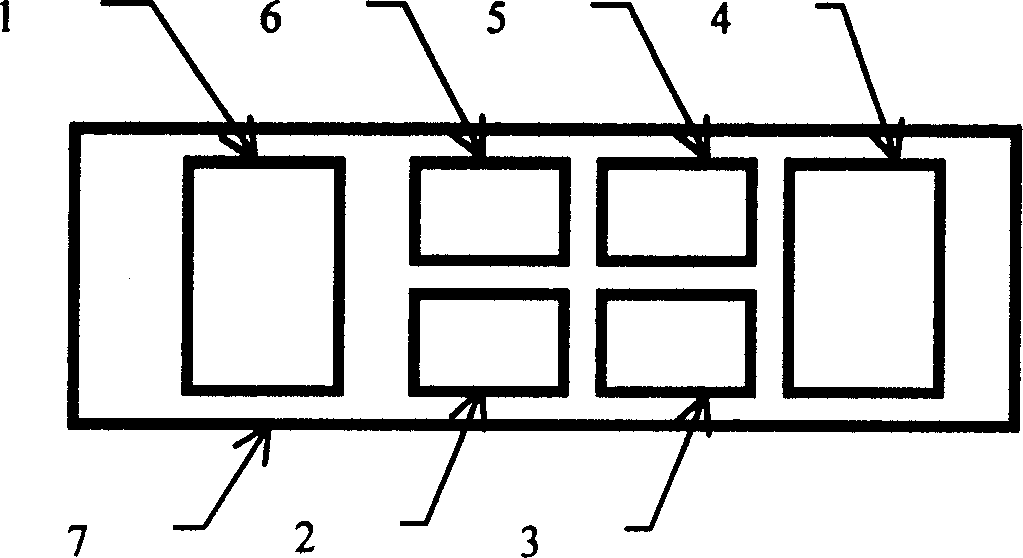

[0012] The laser scanning device consists of a scanning head and a laser generator connected to it. like figure 2 As shown, the scanning heads 2 , 3 , 5 , 6 are equidistantly distributed above the working cylinder 11 . The scanning head achieves focusing, and the laser scanning device realizes selective laser rapid prototyping of powder materials.

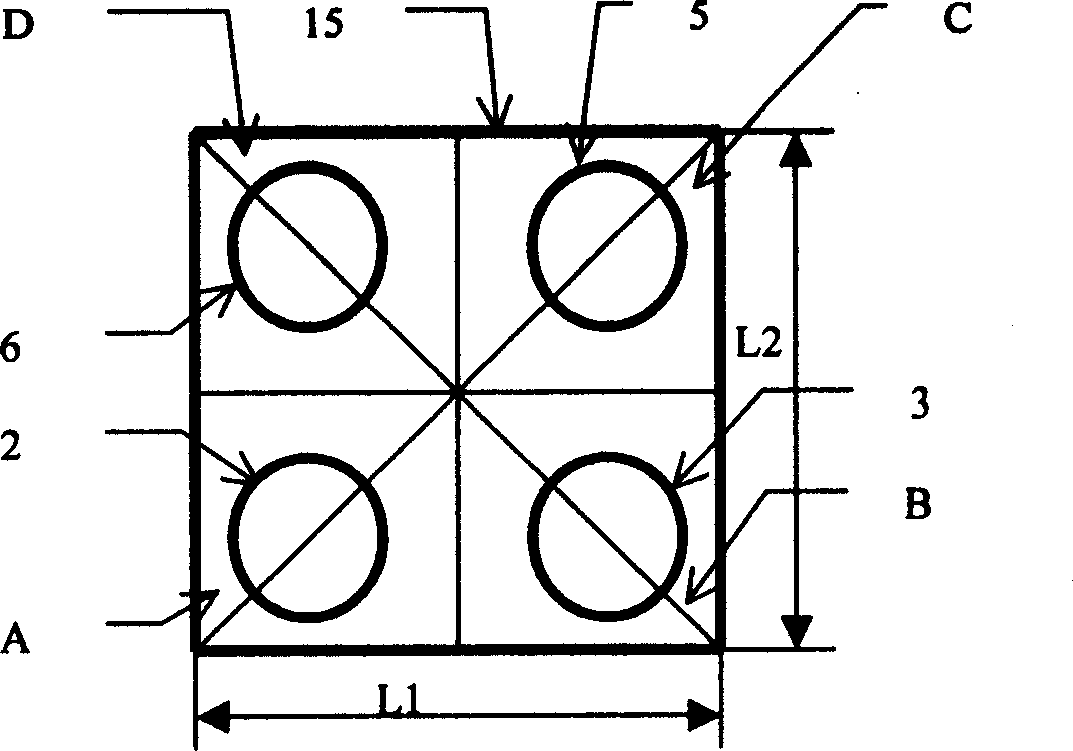

[0013] In order to make them compact, the installation size of the scanning head and the size of the scanning field are arranged equidistantly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com