Liquid crystal device and electronic apparatus

A liquid crystal device and liquid crystal layer technology, applied in folders, optics, printing, etc., can solve the problems of reduced pixel aperture ratio, large gap area, unable to display images, etc., and achieve the effect of excellent viewing angle characteristics and high pixel aperture ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0041] (the whole frame)

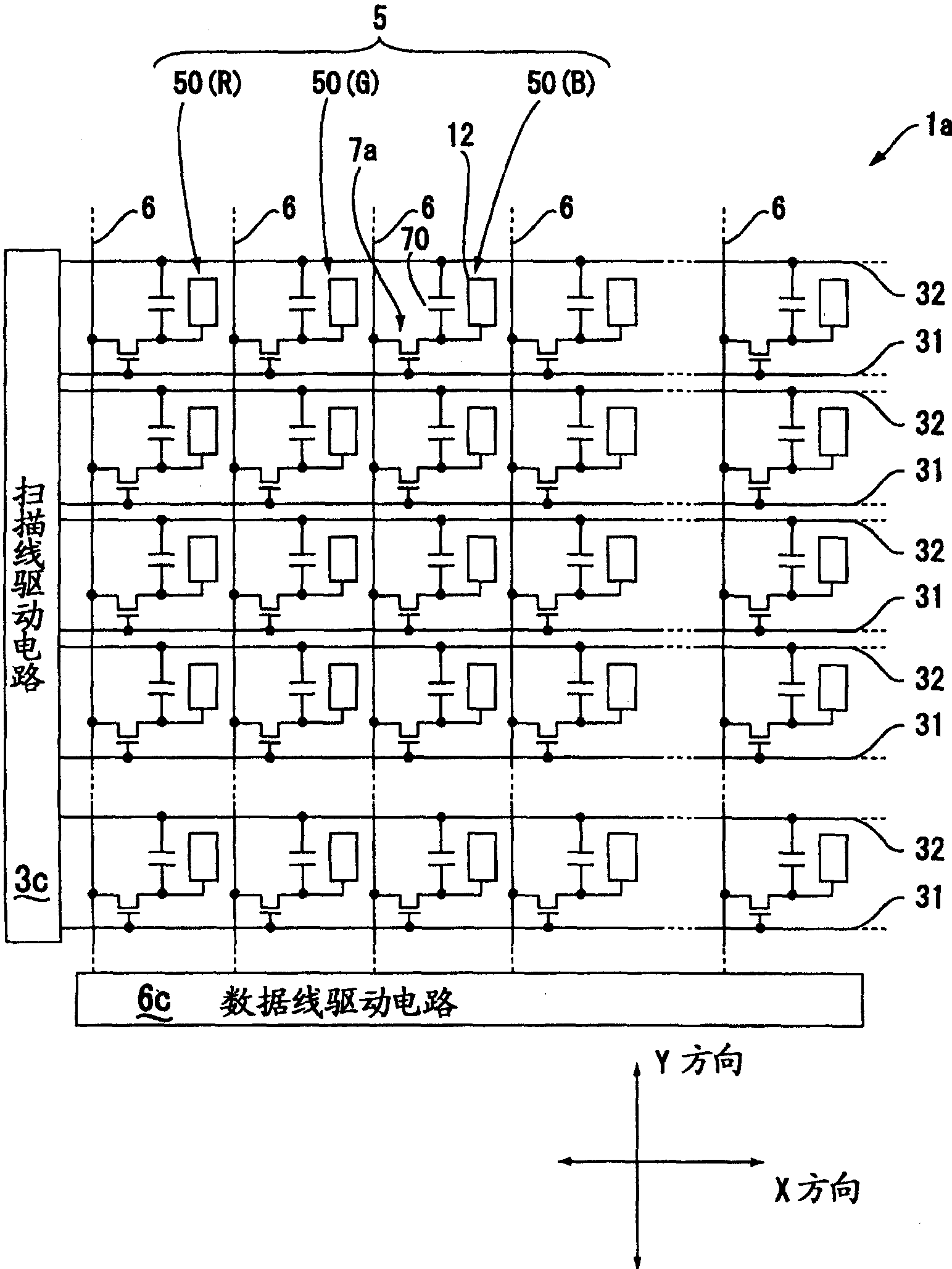

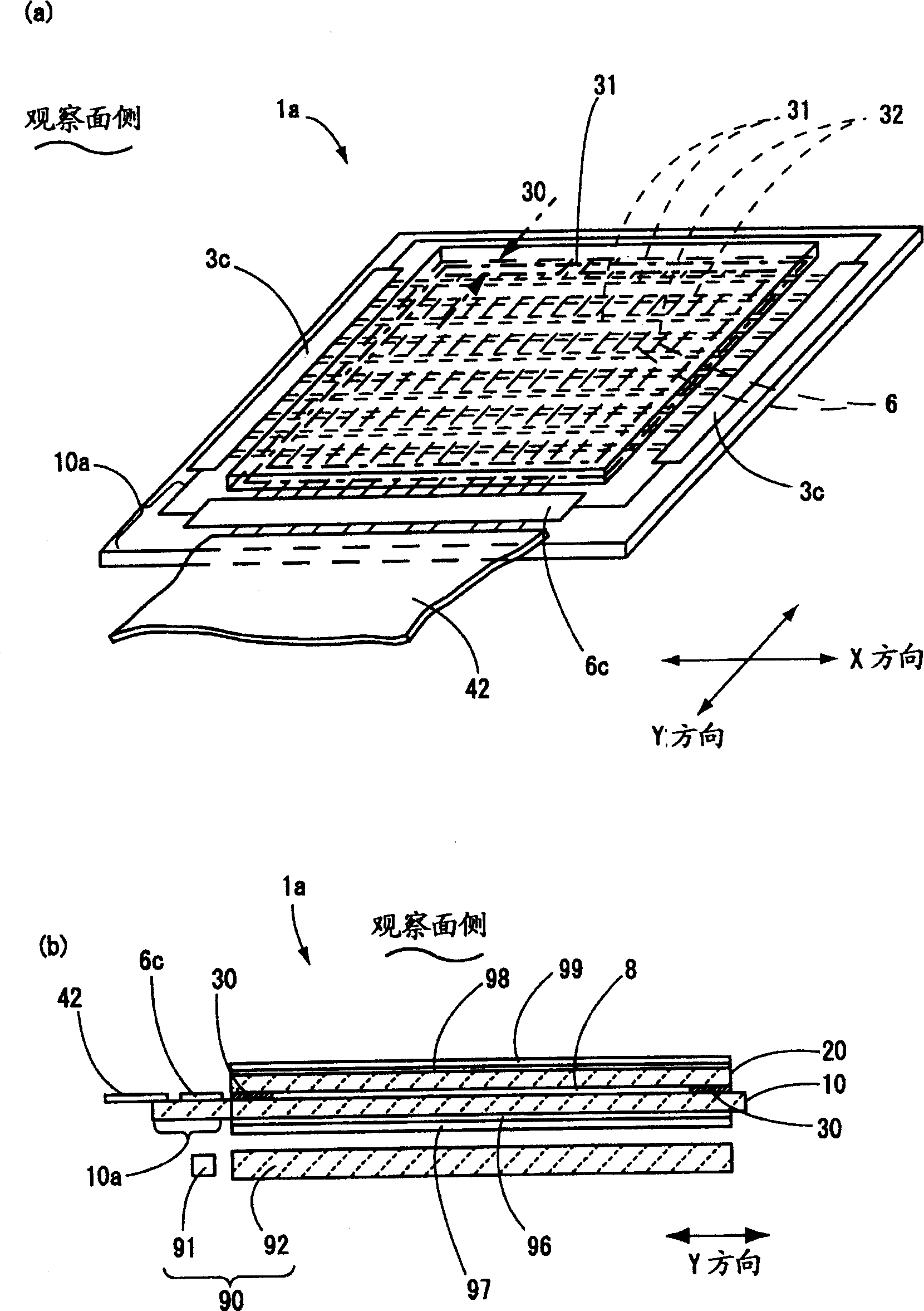

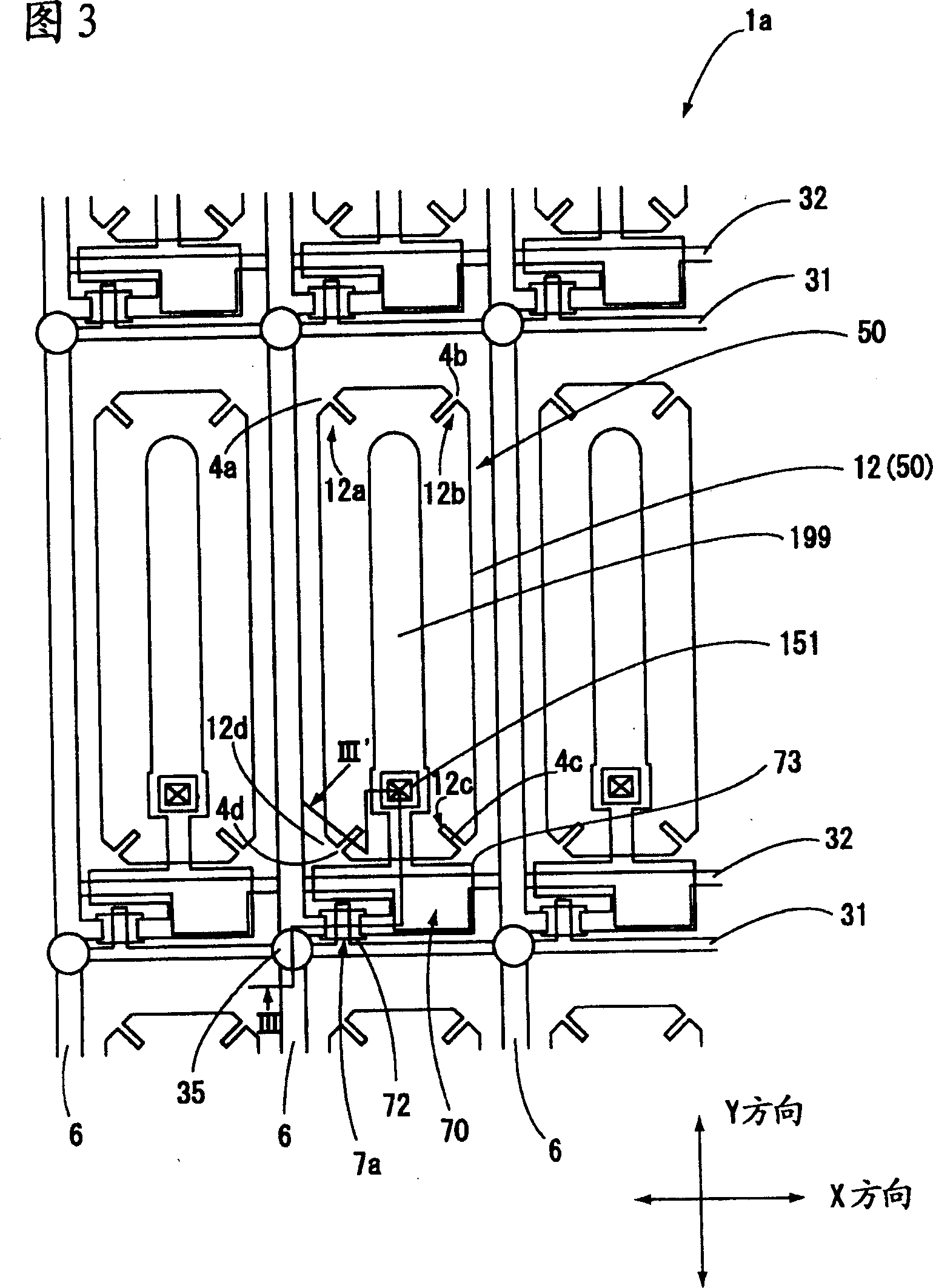

[0042] figure 1 It is a block diagram showing the electrical configuration of the liquid crystal device according to Embodiment 1 of the present invention. figure 2 (a) and (b) are schematic perspective views of the liquid crystal device according to Embodiment 1 of the present invention seen from obliquely above (counter substrate) side, and explanatory diagrams schematically showing a cross-section when the liquid crystal device is cut in the Y direction . In addition, since the liquid crystal device of this form is used for color display, each pixel corresponds to red (R), green (G), and blue (B). (R), (G), (B) to represent.

[0043] figure 1 The shown liquid crystal device 1a is a transmissive active matrix liquid crystal device using TFT (Thin Film Transistor, thin film transistor) as a pixel switching element, and a plurality of scanning lines 31 as signals are formed in the X direction (row direction), A plurality of data lines 6 are f...

Embodiment approach 2

[0060] 5 is a plan view schematically showing a pixel structure in the range of one dot of the liquid crystal device according to Embodiment 2 of the present invention. 6 is an enlarged cross-sectional view showing one of a plurality of pixels formed in the liquid crystal device according to Embodiment 2 of the present invention, and corresponds to the V-V' cross-sectional view in FIG. 5 . Figure 7 (a) and (b) are explanatory diagrams showing equipotential lines when a slit is formed on a sub-pixel electrode in the liquid crystal device according to Embodiment 2 of the present invention. In addition, since the basic structure of the liquid crystal device of this embodiment is the same as that of Embodiment 1, the same parts are shown with the same symbols and their descriptions are omitted.

[0061] The liquid crystal device 1a shown in FIGS. 5 and 6 is also the same as Embodiment 1, and is a transmissive active-matrix liquid crystal device using TFTs as pixel switching eleme...

Embodiment approach 3

[0075]8 is a plan view schematically showing a pixel structure in a range of one dot of a liquid crystal device according to Embodiment 3 of the present invention. 9 is an enlarged cross-sectional view showing one of the plurality of pixels formed in the liquid crystal device according to Embodiment 3 of the present invention, and corresponds to the VIII-VIII' cross-sectional view in FIG. 8 . In addition, since the basic structure of the liquid crystal device of this embodiment is the same as that of Embodiment 1, the same reference numerals are attached to the same parts, and their descriptions are omitted.

[0076] The liquid crystal device 1a shown in FIGS. 8 and 9 is different from Embodiment 1 in that it is a transflective active matrix liquid crystal device. Reflective layer 16 made of aluminum alloy or silver alloy is formed on the following region among the layers of electrode 12 . In addition, the interlayer insulating film 15 is formed using a photosensitive resin a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com