Method for detecting semiconductor micro device bonding strength

A bonding strength and micro-device technology, which is applied in semiconductor/solid-state device testing/measurement, etc., can solve the problems of device electrodes or circuits, adding more solder, and inconvenient bonding, etc., to achieve stable process, simple process, and bond The effect of low combined temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

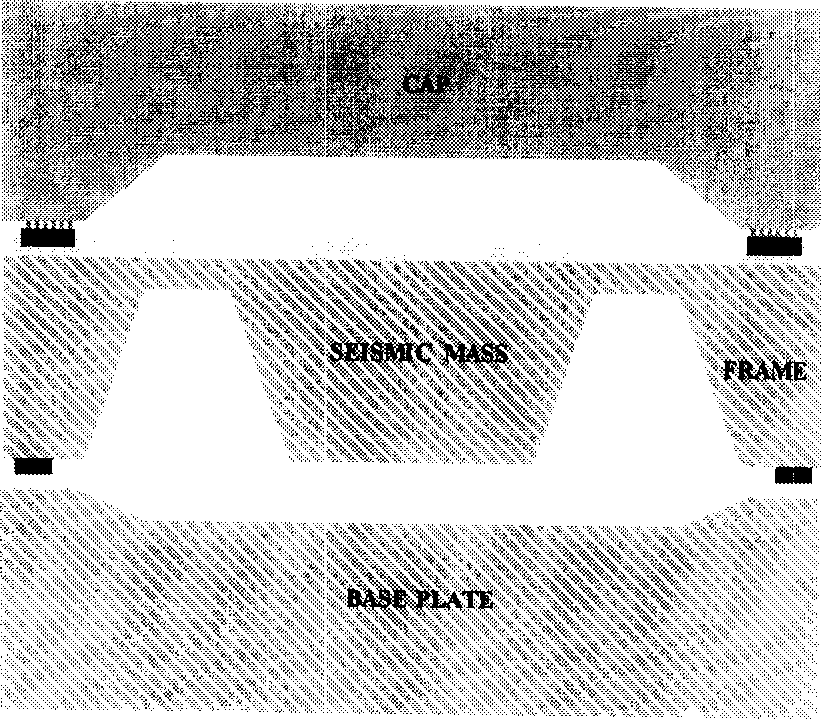

[0044] Example 1. Three-layer bonding of piezoresistive accelerometer

[0045] The cross-sectional structure of the piezoresistive accelerometer is as follows: figure 2 shown. Its three-layer structure needs to be assembled together by bonding. A 4-inch 525 μm thick n-(100) silicon structural wafer is used, and the middle layer is a double-sided polished structural wafer. Firstly, silicon wafers are subjected to a conventional acid boiling process, that is, silicon wafers are soaked in a mixed solution of sulfuric acid and hydrogen peroxide (H 2 SO 4 :H 2 o 2 =4:1) and boiled (about 120°C) for 10 minutes to remove pollutants and hydrocarbons on the surface of the silicon wafer. One surface of the structural sheet is sputtered with a Cr layer of 200-500 Å and an Au layer of about 3000 Å, and its structure is a silicon matrix-SiO 2 / Cr / Au, while the other side is pure silicon base (rinsed with BHF solution before bonding to remove the natural oxide layer) and matrix-SiO ...

Embodiment 2

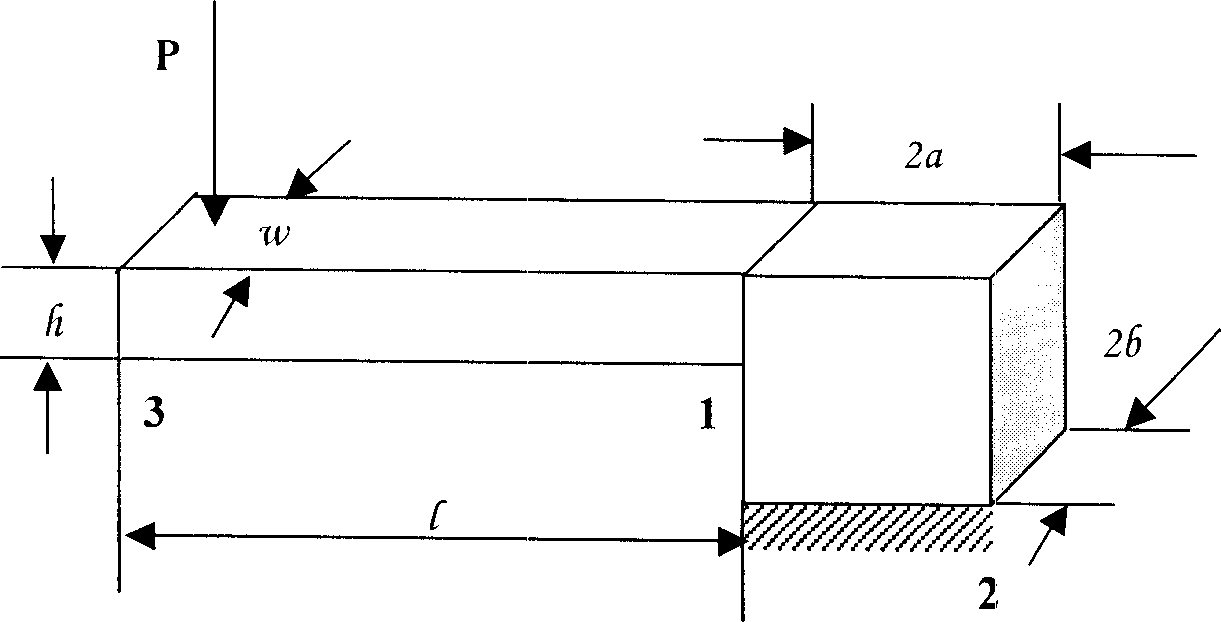

[0053] Embodiment 2: testing bonding strength by pressing arm method

[0054]Compression arm method to test the bonding strength, such as figure 1 Shown:

[0055] According to a series of design calculations, the length range of the pressing arm can be obtained:

[0056] 4 a 3 [ σ 2 ] - 2 Pa 3 P ≤ l ≤ ah 2 [ σ 1 ] 3 P - - - ( I )

[0057] Substituting the relevant parameters, it can be approximat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com