Preparation method of nano filtration drinking water based on seconddary membrane filtering technology

A filtration technology, direct drinking water technology, applied in the field of nanofiltration direct drinking water preparation based on secondary membrane filtration technology, can solve the problems of unsafe drinking water, heavy load of nanofiltration equipment, short gap time, etc., to reduce equipment operation and maintenance cost, ease of cleaning and regeneration, and the effect of reducing the cost of membrane replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

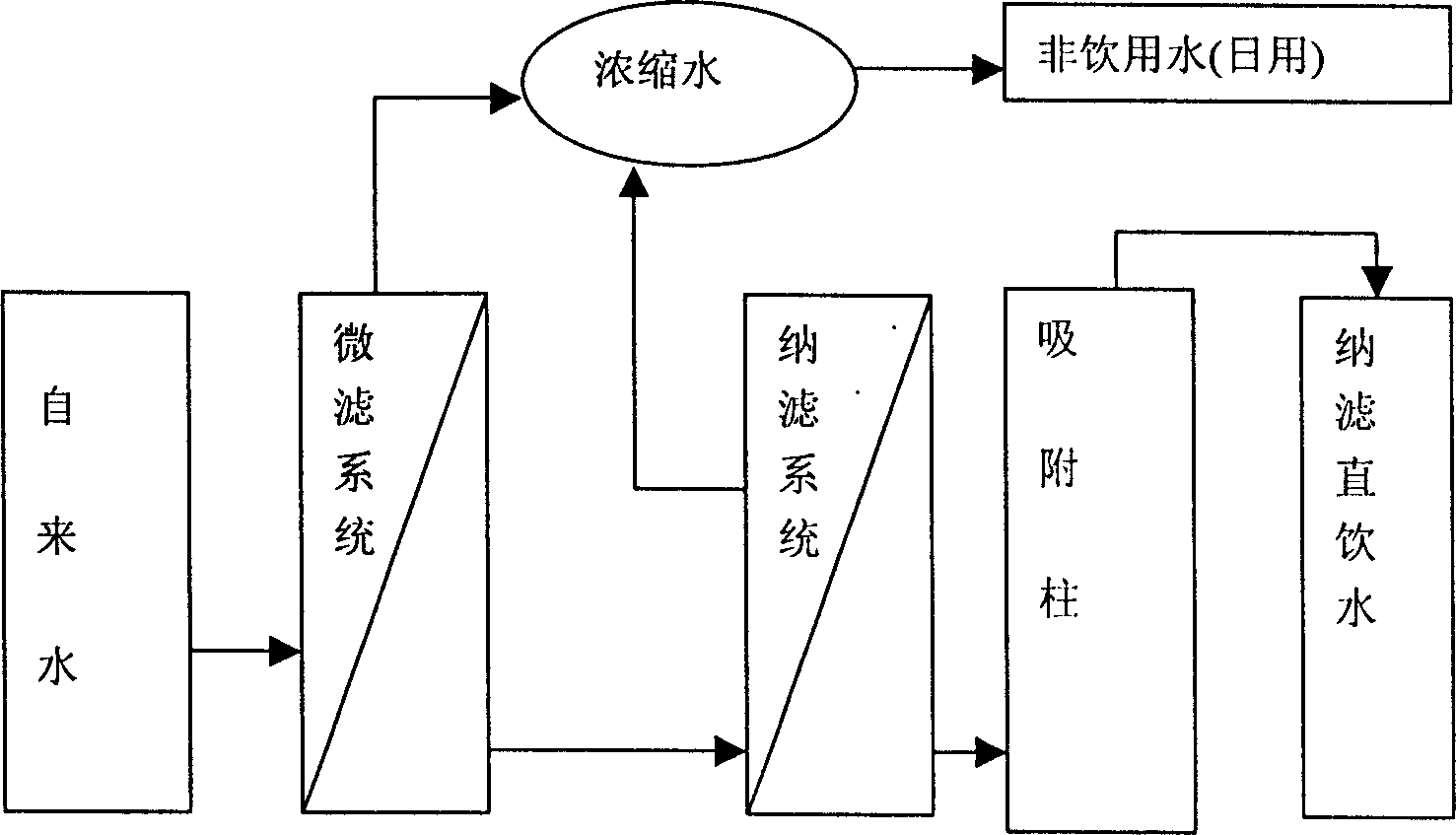

[0032] See figure 1, The tap water with a pressure of 3bar is filtered through a microfiltration system to obtain microfiltration water and microfiltration concentrated water. Micro-filtered water is used as the raw material for further production of direct drinking water into the next process, and the micro-filtered concentrated water is recycled as daily sanitary water. Use microfiltration to remove harmful impurities such as suspended solids, bacteria, other precipitates, and macromolecular compounds in tap water. The membrane used in the microfiltration system is a ceramic membrane with a molecular weight cut-off of 300,000 MWCO. The working condition of microfiltration is normal temperature, the working pressure difference is 1.5bar, that is, the inlet pressure is 3bar and the outlet pressure is 1.5bar. The microfiltration water obtained by the microfiltration treatment is pumped into the nanofiltration system with an increasing pump for filtration, and nanofiltration water a...

Embodiment 2

[0034] Similar to Example 1, the difference is that the membrane used in the microfiltration system is a metal membrane with a molecular weight cut-off of 450,000 MWCO, and the working pressure difference is 1.3 bar, that is, the inlet pressure is 2.8 bar and the outlet pressure is 1.5 bar.

Embodiment 3

[0036] Similar to Example 1, the difference is that the membrane used in the microfiltration system is a ceramic membrane with a molecular weight cut-off of 650,000 MWCO. The working pressure difference is 1bar, that is, the inlet pressure is 2.8bar, and the outlet pressure is 1.8bar. The nanofiltration membrane material used in the nanofiltration system is a polyethersulfone nanofiltration membrane with a molecular weight cut-off of 150MWCO. The inlet pressure: 35.5bar, the outlet pressure: 33.2bar, and the working pressure difference is 2.3bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com