Method for catalytic hydrogenation dehalogenation of halogenated phenols

A halogenated phenol and catalytic hydrogenation technology, applied in the field of halogenated phenol compound catalytic hydrodehalogenation, can solve problems such as low conversion rate, and achieve the effects of easy control of operation, mild reaction conditions and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

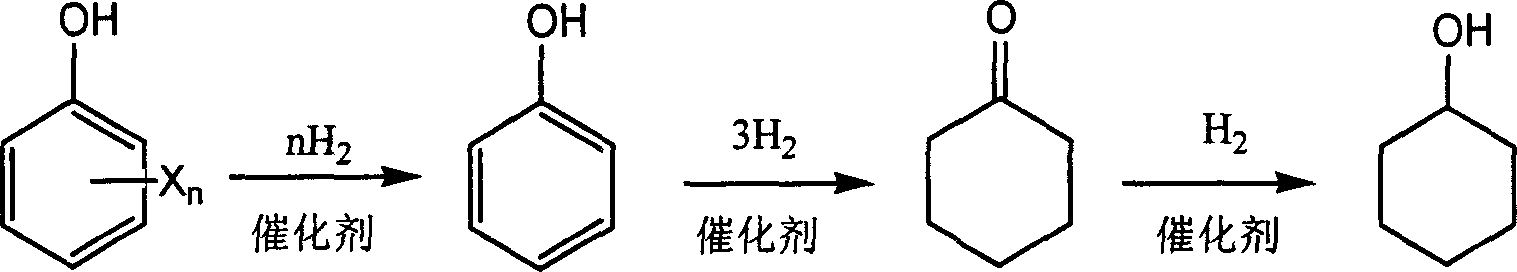

Method used

Image

Examples

example 1

[0018] Example 1, the preparation of catalyst

[0019] Dissolve a certain amount of palladium chloride in concentrated hydrochloric acid, dilute it with water, impregnate it into activated carbon, and evaporate to dryness under constant stirring. The obtained solid is ground into powder, reduced by hydrogen, and then sealed and stored to obtain palladium / carbon catalysts with different contents. Palladium / carbon catalysts with different contents are listed in Table 1

example 2

[0020] Example 2, according to the preparation process of the catalyst described in Example 1, except that the active component and the carrier are different, all the other processes are the same, and the supported catalysts of different carriers and different active components are prepared, and the prepared catalyst is listed in Table 1.

example 3

[0021] The preparation of example 3, Raney Ni

[0022] Dissolve a certain amount of NaOH in water, put it into a beaker and cool it with ice. Add a certain amount of powdered Ni-Al alloy, and add in small amounts under constant stirring until the addition is complete. Heat at 115-120°C for 4 hours, then add 440 ml of NaOH solution, keep it for a while until there is no more H 2 Generated, add water after cooling. Use the pouring method to remove the supernatant, add water and stir, and then remove the supernatant after precipitation, and then wash the catalyst repeatedly until the washing liquid is neutral to the stone reagent, then wash it with 95% ethanol for 5 times, and store it. in ethanol covered with a glass stopper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com