Sold liquid separation machine with flexible tubular frame and multiple utilization method thereof

A tubular and flexible technology, which is applied to flexible tubular solid-liquid disposal machines and its various fields of use, can solve the problems that the slag discharge speed is not as good as that of the reciprocating slag discharge piston mechanism, and the structure is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

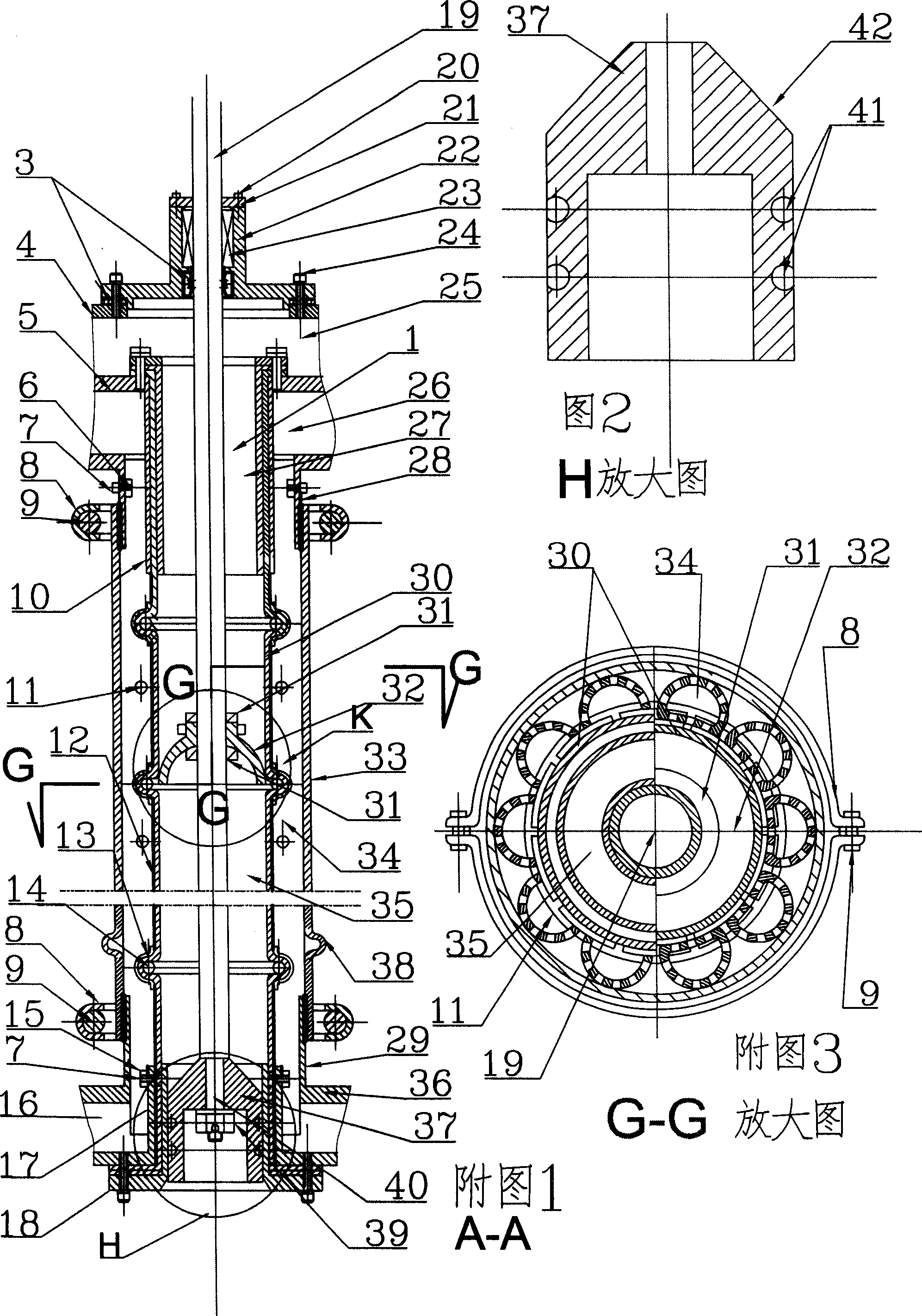

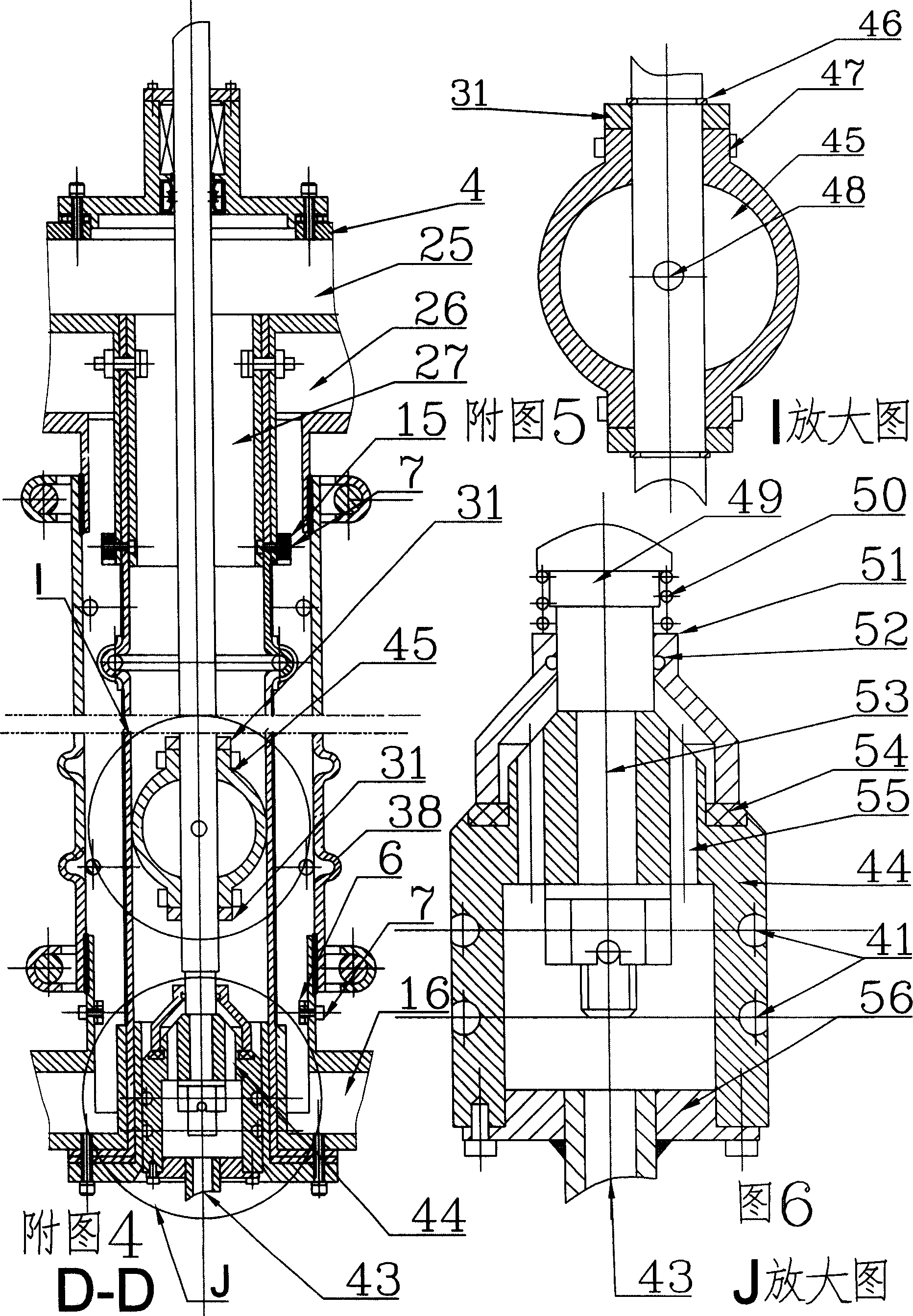

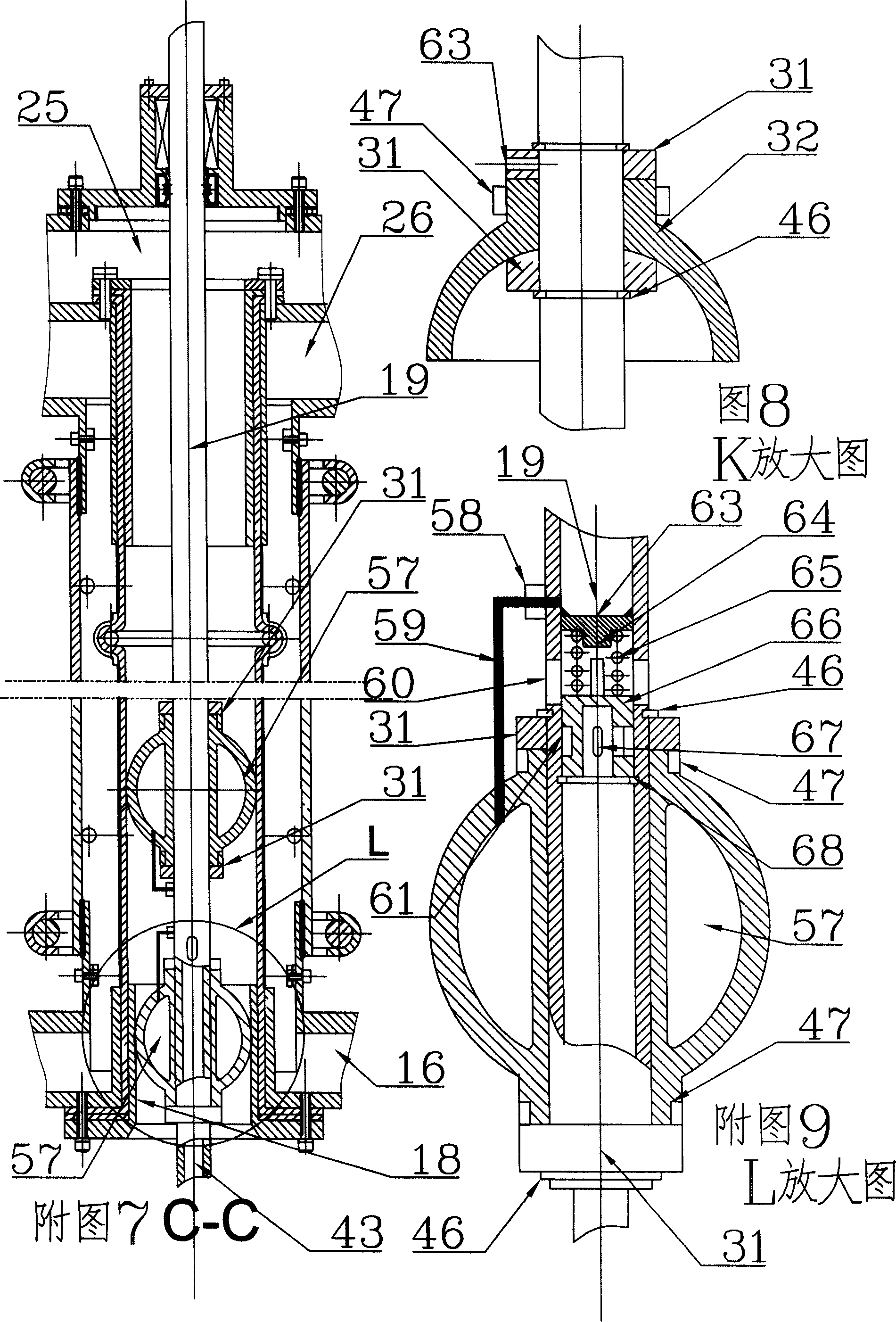

[0082] The solid-liquid disposer of the present invention will be further described below in conjunction with the accompanying drawings.

[0083]In Figures 1, 13, 14 and 18, the membrane module 2 includes 4 membrane units, the upper flange chamber 4 and the lower flange chamber 36; the circle centerlines of the 4 membrane units in the membrane module are aligned in a straight line (row axis), the row axes of the four membrane modules of the filter element are parallel to each other. The membrane unit comprises the following flexible elements: a tubular filter membrane 30 , a tubular filter membrane outer support frame 12 , a tubular grid and a tubular closure membrane 33 . The support frame 12 is a flexible porous net (not shown in the thin figure of the net), and the porous net has a porosity below 95% after being unfolded into a plane; the tubular sealing membrane 33 adopts a flexible thin-walled tube without leakage. ; their centerlines coincide and are perpendicular to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com