Active energy radiation hardenable skin plaster composition and skin plaster

A technology of active energy and skin patches, applied in the direction of non-polymer organic compound adhesives, active ingredients of heterocyclic compounds, drug combinations, etc., can solve problems such as yellowing, exudation, and working environment problems of cured films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

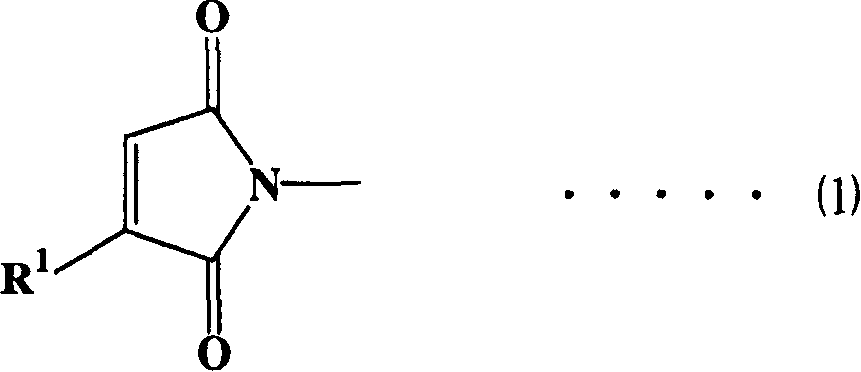

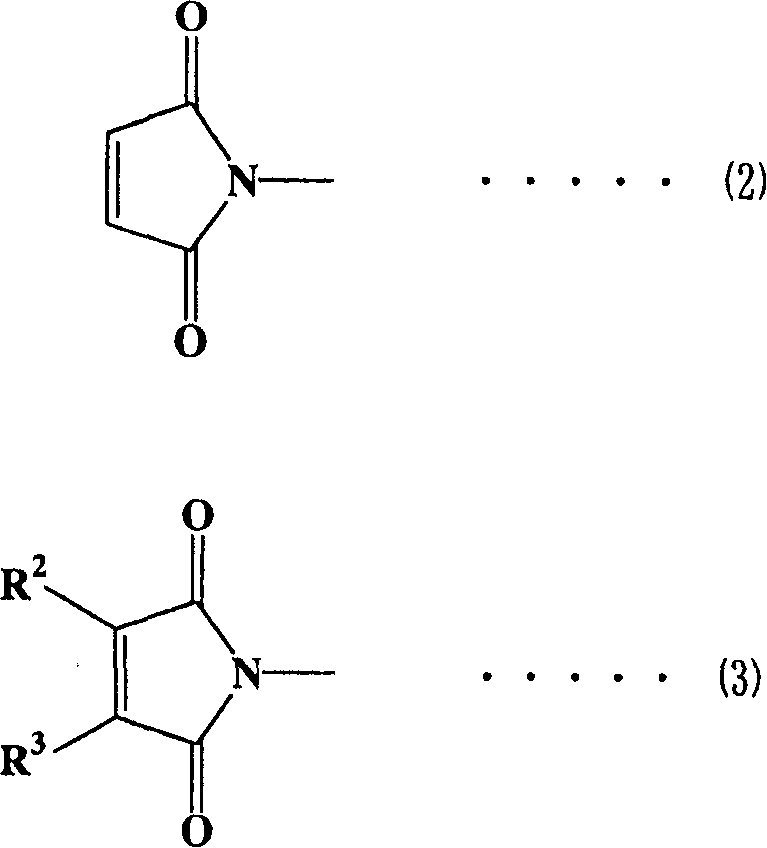

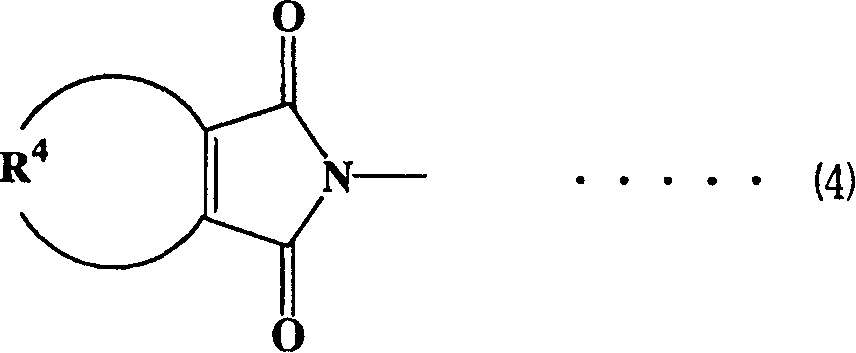

[0240] The composition of the present invention must only include the above-mentioned components (A) and (B) as essential components; as component (A) is preferably as follows.

[0241] Specifically, a component that is liquid at normal temperature is preferable as component (A). Furthermore, the above-mentioned component (I) or (II) is preferable as the component (A). Preference is given to components having a polyether backbone and a polyester backbone as component (A); components having a polyether backbone are particularly preferred. In addition, it preferably has a number average molecular weight of 1,000 to 20,000 as the component (A).

[0242] In addition, the composition of the present invention preferably contains a pharmaceutical component.

Embodiment 1 to 13 and comparative example 1 to 7

[0271] Using the maleimide compounds produced in the above production examples and comparative production examples, a composition for skin patches was produced according to the formulation given in Table 2 by the following method: the components were thoroughly mixed until the mixture became uniform, and then defoaming.

[0272] The obtained composition was coated with a thickness of 50 μm on the surface of a polyester film with a thickness of 50 μm as a substrate sheet, and a high-pressure mercury lamp (one lamp; 10 cm High), the sheet was passed 4 times at a transport speed of 10 m / min, and ultraviolet light was irradiated from the coated surface (accumulated amount of light = 1200 mJ / cm 2 ), whereby the composition is cured to produce a patch.

[0273] It should be noted that in Example 10 and Comparative Example 6, the composition was heated to 50°C and then applied, and in Comparative Example 7, C1 was heated to 80°C to melt and then applied.

[0274] In each of Example...

Embodiment 14 to 24

[0311] Examples 14 to 24 (Patch Compositions Containing Drug Components)

[0312] Using the maleimide compound produced in the above Production Example, a composition for a skin patch was produced according to the formulation given in Table 3 by mixing the components well until the mixture became uniform, followed by defoaming.

[0313] The obtained composition is coated with the thickness of the composition layer given in Table 3 on the surface of a polyester film with a thickness of 50 μm as the substrate sheet, and is concentrated under high pressure at 120W / cm with a UV irradiator equipped with a transmission belt. Under a mercury lamp (one lamp; 10 cm high), the sheet is passed repeatedly at a conveying speed of 10 m / min, and ultraviolet light is irradiated from the coated surface until the cumulative amount of light reaches the value given in Table 3 (each pass Accumulated amount of light = 300mJ / cm 2 ), whereby the composition is cured to produce a patch.

[0314]The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com