Pressure-sensitive adhesive sheet

An adhesive sheet and adhesive layer technology, applied in pressure-sensitive films/sheets, adhesive additives, film/sheet release coatings, etc., can solve problems such as insufficient peelability and reduced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] 98 parts of methyl methacrylate and 2 parts of acrylic acid were copolymerized in a conventional manner to obtain a solution containing an acrylic polymer having a weight average molecular weight of 80,000 (glass transition temperature, 95° C.).

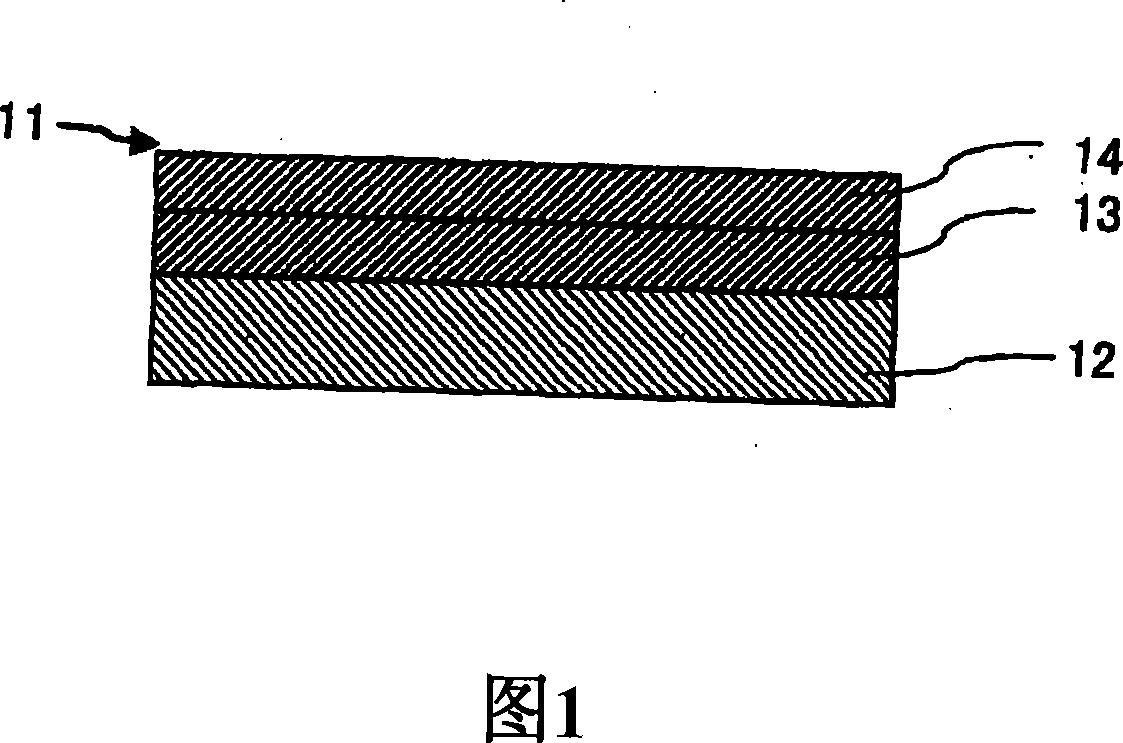

[0099] The solution containing the acrylic polymer was then applied onto a separator and dried to form an intermediate layer (thickness, 5 μm). This intermediate layer was transferred onto a flexible polyvinyl chloride film (substrate, with a thickness of 100 μm). Incidentally, the flexible polyvinyl chloride film contains DOP (dioctyl phthalate) as a plasticizer.

[0100]Subsequently, 50 parts of methyl acrylate, 20 parts of 2-ethylhexyl acrylate, and 5 parts of acrylic acid were copolymerized in a conventional manner to obtain a solution containing an acrylic polymer having a weight average molecular weight of 1,000,000. To 100 parts of this solution was added 3 parts of 2,2-dimethoxy-1,2-phenylethan-1-one (trade name "Irga...

Embodiment 2

[0103] This example differs from Example 1 in that an acrylic polymer containing poly(methyl methacrylate) is used as an intermediate layer constituent material instead of the acrylic polymer used in Example 1. The acrylic polymer including poly(methyl methacrylate) had a weight average molecular weight of 50,000 and a glass transition temperature of 105°C. The pressure-sensitive adhesive sheet obtained in this example is referred to as pressure-sensitive adhesive sheet B.

Embodiment 3

[0105] In this example, an intermediate layer constituting material prepared in the following manner was used. In place of the acrylic polymer used in Example 1, an acrylic polymer comprising NK-380 (trade name; manufactured by Nippon Shokubai Co., Ltd.) having an amino group introduced by graft copolymerization was prepared. To 100 parts of this acrylic polymer were added 20 parts of an epoxy crosslinking agent (trade name, Epikote 828; manufactured by Japan Epoxy Resins Co., Ltd.) and 40 parts of dioctyl phthalate as a plasticizer . Thus, a material for constituting the intermediate layer was prepared. The pressure-sensitive adhesive sheet C of this example was prepared in the same method as in Example 1 except using this material. The acrylic polymer including NK-380 had a weight average molecular weight of 70,000 and a glass transition temperature of 90°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com