A novel hybridized non-ion fluorin surfactant and synthesis method thereof

A fluorosurfactant and non-ionic technology, applied in the field of new hybrid non-ionic fluorosurfactant and its synthesis, can solve problems such as complex formula design, affecting the performance of the compound, and difficulty in obtaining the best effect, and achieve production High conversion rate, ability to reduce surface tension, and non-polluting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

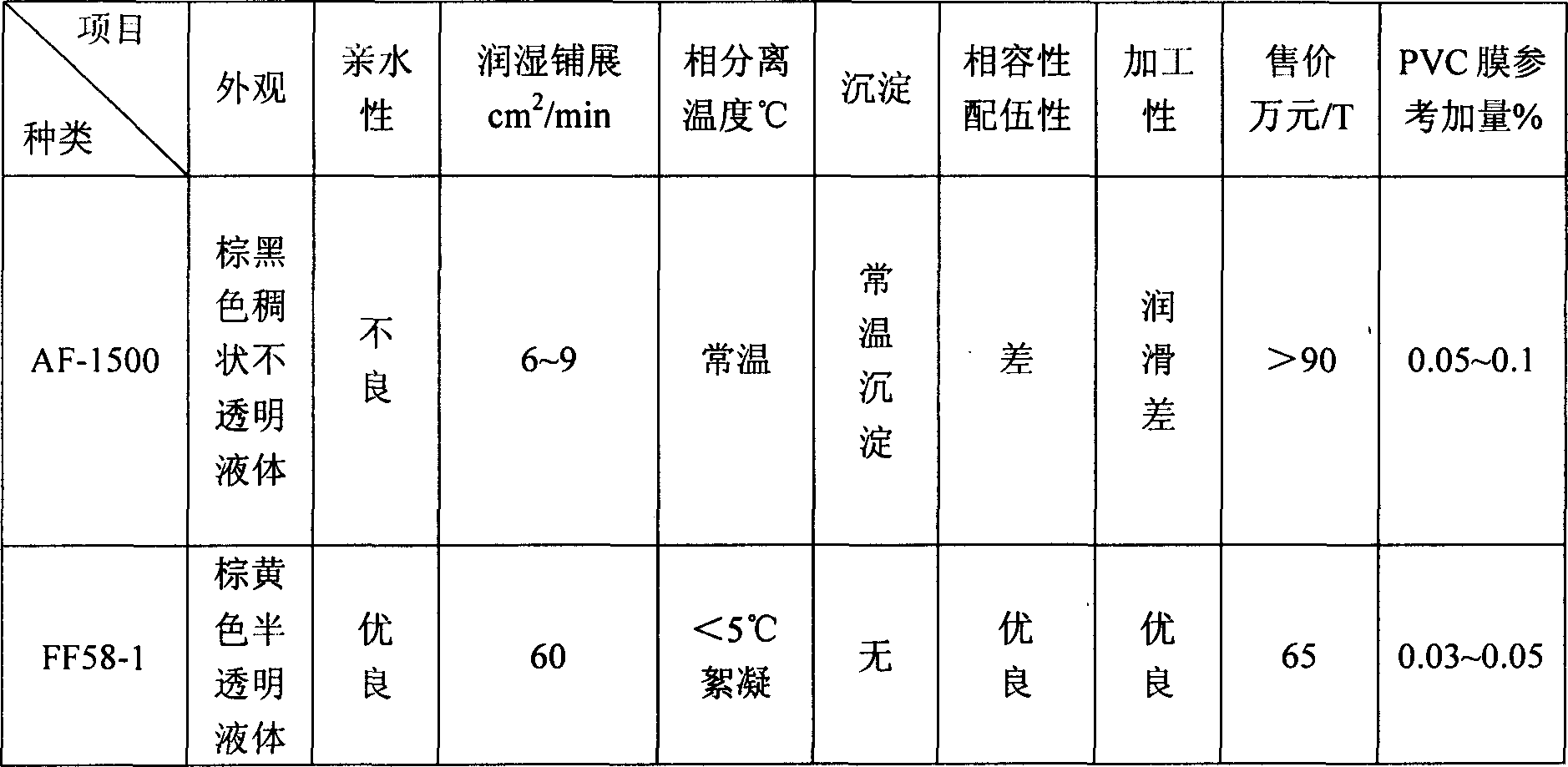

Image

Examples

Embodiment 1

[0053] Embodiment 1: the synthesis of the hybrid type nonionic fluorosurfactant containing sodium ion

[0054] Add polymerized glycerin and perfluoro or fluorinated alkyl carboxylic acid with 4 to 16 carbon atoms into the reactor in an equimolar ratio or a ratio of 1.5:1, and stir under negative pressure at 140°C to 200°C under nitrogen protection carry out esterification reaction. When the reaction temperature reaches above 120°C, start to monitor the pH value of the reactant. When the pH value reaches 3.5, stop heating to slow down the esterification reaction. Slowly add NaHCO in batches when the temperature is lowered to 120°C 3 Aqueous solution, continue to monitor the pH value to 6.5±0.5, stop adding liquid caustic soda NaHCO 3 , the product is C n f 2n+1 The anionic fluorosurfactant of COONa continued to react for 30 minutes and was regarded as the end point. Then cool down to 60°C naturally under stirring to discharge the material. This period of time can promote ...

Embodiment 2

[0071] Embodiment 2: the same reason can be added by adding K 2 CO 3 or KHCO 3 The aqueous solution obtains the hybrid type nonionic fluorosurfactant containing potassium ion:

[0072] (1) When n=4; m=2; x=1; R=CH 2 ;M=K + Time;

[0073] C 4 f 9 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 2 OH·(C 4 f 9 COOK)

[0074] C 4 f 9 CH 2 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 2 OH·(C 4 f 9 CH 2 COOK)

[0075] C 4 f 9 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 2 OH·(C 4 f 9 CH 2 COOK)

[0076] C 4 f 9 CH 2 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 2 OH·(C 4 f 9 COOK)

[0077] (2) When n=10; m=15; x=31; R=(CH 2 ) 9 ;M=K + , the new hybrid nonionic fluorosurfactant is

[0078] C 10 f 21 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 15 OH·(C 10 f 21 COOK) 31

[0079] C 10 f 21 (CH 2 ) 9 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 15 OH·[C 10 f 21 (CH 2 ) 9 COOK] 31

[0080] C 10 f 21 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 15 OH·[C 10 f 21 (CH 2 ) 9 COOK] 31

[0081] C 10...

Embodiment 3

[0087] Embodiment 3: also can be by adding NH 3 HCO 3 Aqueous solution or NH 4 Water yields a hybrid nonionic fluorosurfactant containing ammonia ions.

[0088] (1) When n=4; m=2; x=1; R=CH 2 ;M=NH 4 + Time;

[0089] C 4 f 9 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 2 OH·(C 4 f 9 COONH 4 )

[0090] C 4 f 9 CH 2 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 2 OH·(C 4 f 9 CH 2 COONH 4 )

[0091] C 4 f 9 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 2 OH·(C 4 f 9 CH 2 COONH 4 )

[0092] C 4 f 9 CH 2 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 2 OH·(C 4 f 9 COONH 4 )

[0093] (2) When n=10; m=15; x=31; R=(CH 2 ) 9 ;M=NH 4 + , the new hybrid non-ionic fluorosurfactant is

[0094] C 10 f 21 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 15 OH·(C 10 f 21 COONH 4 ) 31

[0095] C 10 f 21 (CH 2 ) 9 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 15 OH·[C 10 f 21 (CH 2 ) 9 COONH 4 ] 31

[0096] C 10 f 21 COOCH 2 CHOHCH 2 (CHOHCHOHCH 2 ) 15 OH·[C 10 f 21 (CH 2 ) 9 COONH 4 ]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com