Process for producing porous poly(ethylene terephthalate) fine denier filament by using single plate

A polyethylene terephthalate and veneer technology, which is applied in the technical field of veneer production of 250-300-hole polyethylene terephthalate fine denier filaments, can solve the problem of high use cost and unsatisfactory use Requirements, uneven cooling of inner and outer layers of tow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

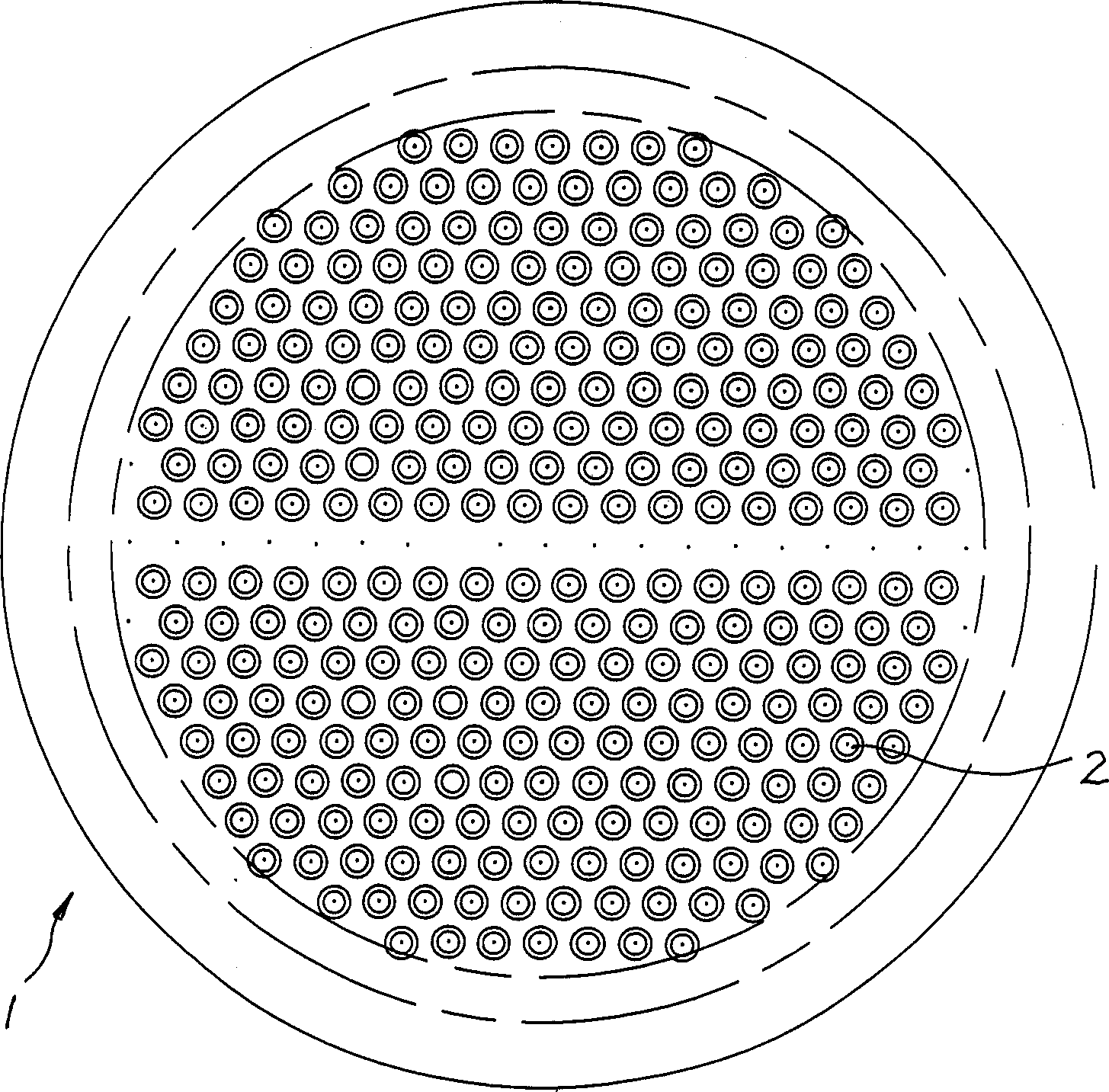

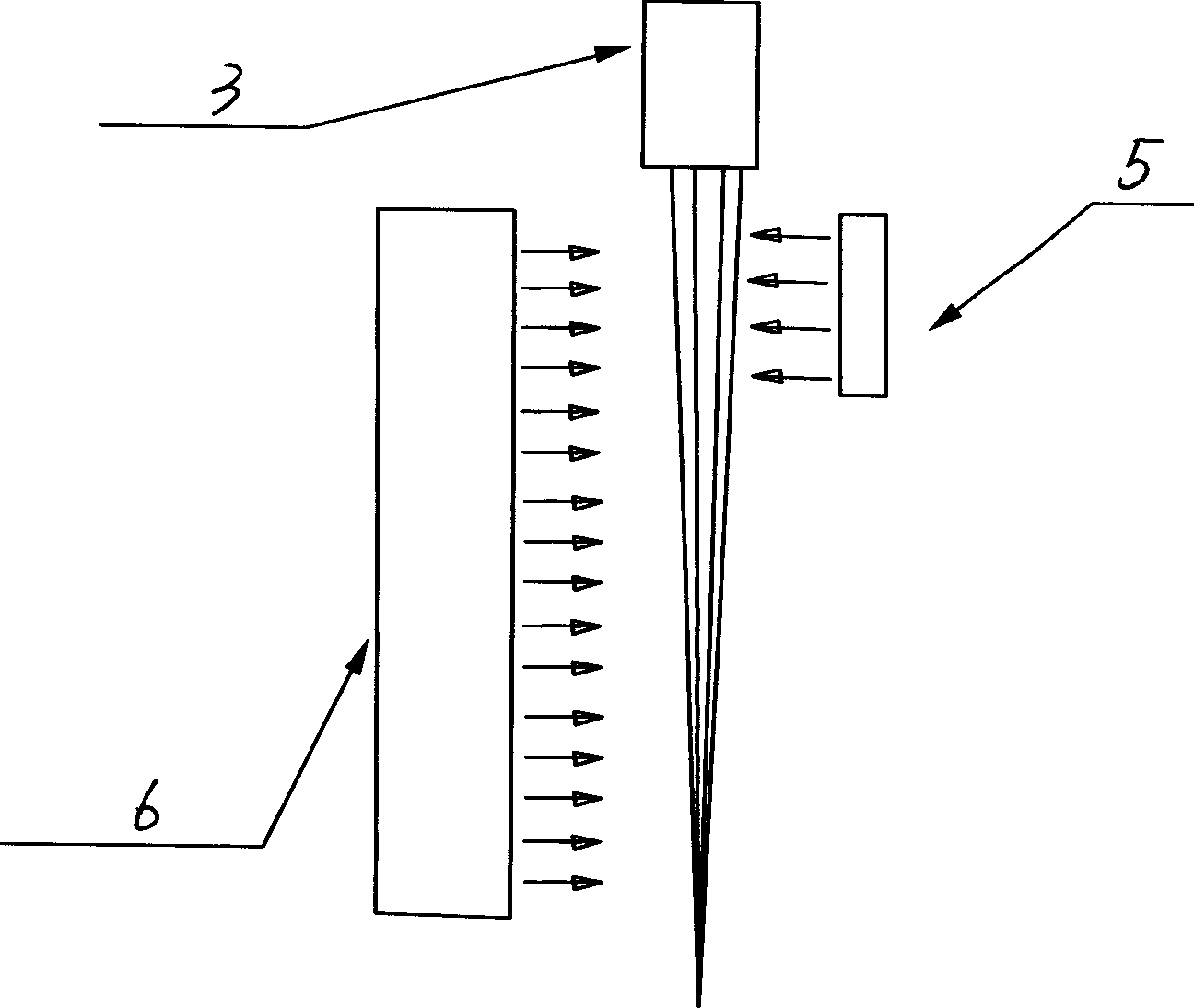

[0033] Example 1: Production of POY (pre-oriented yarn) with 150 denier / 288 strands (final denier of textured yarn). The diameter of the spinneret is 100 mm, distributed in a diamond shape, regardless of filaments; component selection: the filter material is metal sand, the component pressure is 150 kg / cm2, each spinning position has 10 components, and the component center distance is 127 mm ; Spinning temperature: 293°C; Side blowing window: 1.2 meters high, with honeycomb panels inside, so that the wind is in a uniform laminar flow state; an arc-shaped plate 5 is installed outside the side blowing window, and the arc-shaped plate 5 consists of 10 pieces Composed of semi-circular stainless steel sheets with a radius of 63.5 mm (refer to attached Figure 4 shown); oil content: 0.4-0.45%; winding speed: 2800 m / min. Implementation effect: production is unstable, evenness CV value (the coefficient of variation of the calculated silk thickness change) is greater than 1.6%, the fu...

example 2

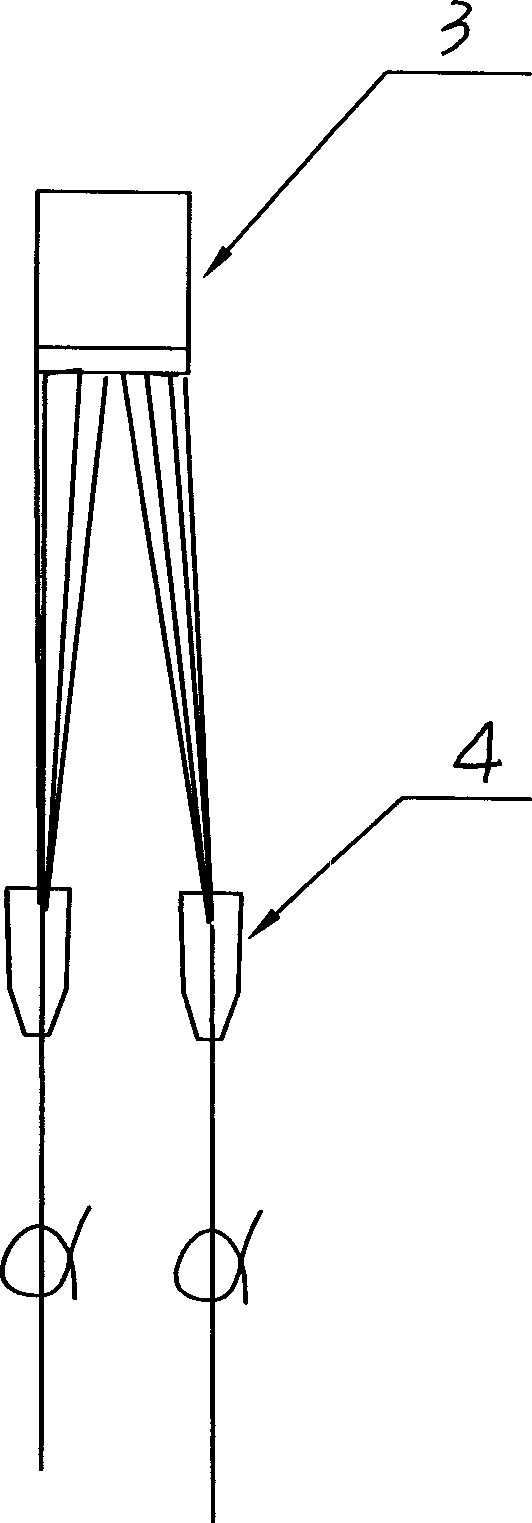

[0034] Example 2: Production of POY (pre-oriented yarn) with 150 denier / 288 strands (final denier of textured yarn). The diameter of the spinneret is 100 mm, and the spinneret holes are distributed in a diamond shape; component selection: the filter material is metal sand, the component pressure is 150 kg / cm2, each spinning position has 10 components, and the center distance of the components is 127 mm; Wire temperature: 293°C; side blower window: 1.2 meters high, with honeycomb panels inside, so that the wind is in a uniform laminar flow state; an arc-shaped plate 5 for wind protection is installed on the outside of the side blower window, and the arc-shaped plate 5 is 10 It consists of a semicircular stainless steel sheet with a radius of 63.5 mm (refer to the attached Figure 4shown); the silk extruded from the spinneret is divided into two parts, the double oil nozzles are oiled, and they are jointed before the godet; oil content: 0.4-0.45%; winding speed: 2800 m / min. Imp...

example 3

[0035] Example 3: POY (pre-oriented yarn) of 200 denier / 288 strands (final denier of textured yarn) was produced. The diameter of the spinneret is 100 mm, and it is distributed in a diamond shape; component selection: the filter material is metal sand, and the component pressure is 150 kg / cm2; each spinning position has 10 components, and the component center distance is 127 mm; spinning temperature: 292°C; side blower window: 1.2 meters high, with honeycomb panels inside, so that the wind is in a uniform laminar flow state; an arc-shaped windshield is installed on the outside of the side blower window, and the windshield is made of 10 semicircular stainless steel Composed of sheets, with a radius of 63.5 mm; the filaments extruded from the spinneret are divided into two, double oil nozzles are oiled, and jointed before the godet; oil content: 0.42%; winding speed: 2850 m / min. Implementation effect: stable production, evenness CV value is less than 1.35%, full roll rate is gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com