Insulating method and structure for workshop operating side and inner side of external wall

A technology for operating surfaces and exterior walls, which is applied to building structures, building components, and building insulation materials. Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

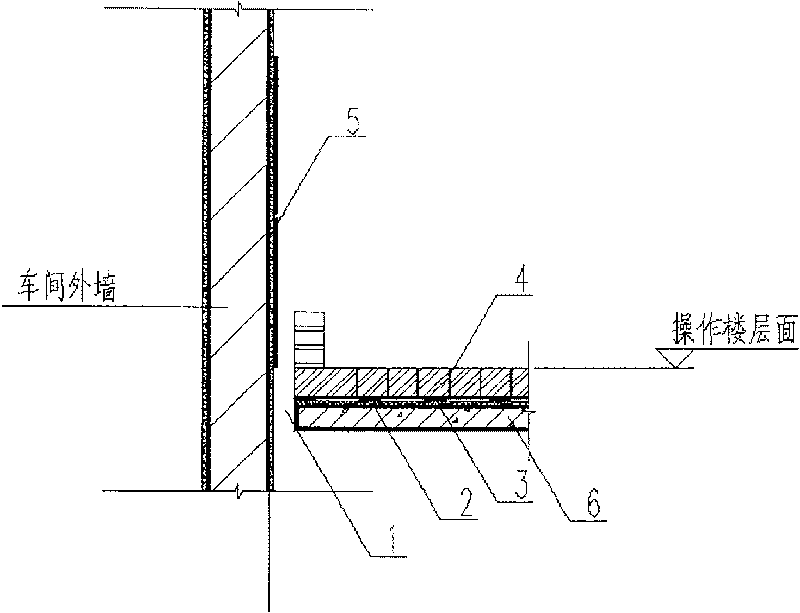

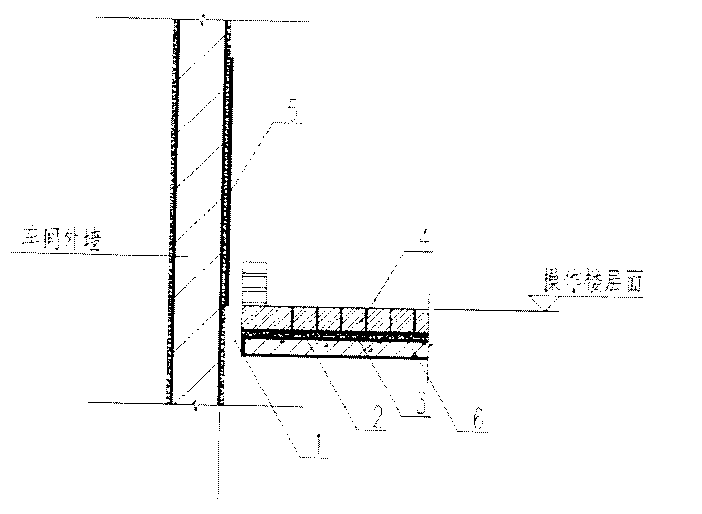

[0011] The embodiment of the present invention: firstly make the cast-in-place reinforced concrete operation floor slab 6 in the factory to separate it from the outer wall to form an air insulation seam 1 with a width of 100mm, and place it on the cast-in-place reinforced concrete operation floor 6 Make a 20mm thick, 1:3 cement mortar leveling layer 2, and apply a layer of chlorosulfonated rubber coating waterproof insulation layer 3 on the surface of the cement mortar leveling layer 2. The chlorosulfonated rubber coating can be directly used as a finished product on the market. Then paste the 113mm-thick insulating surface layer 4 of acid-resistant clinker brick on the surface of the waterproof insulating layer 3 with water glass mastic; in order to prevent the moving tools and equipment on the operation surface from directly contacting the outer wall, the acid-resistant clinker brick insulation surface layer at the end of the operating floor 6 4 Turn up by 215mm to form a reli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com